Method for manufacturing high-voltage electrolytic capacitor

A manufacturing method, high-voltage electrolysis technology, applied in the direction of electrolytic capacitors, capacitors, capacitor dielectric layers, etc., can solve the problems of reduced dielectric oxide film withstand voltage performance, affecting the uniformity and compactness of dielectric oxide film, etc., to ensure the withstand voltage Performance, the effect of reducing the chance of being broken down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

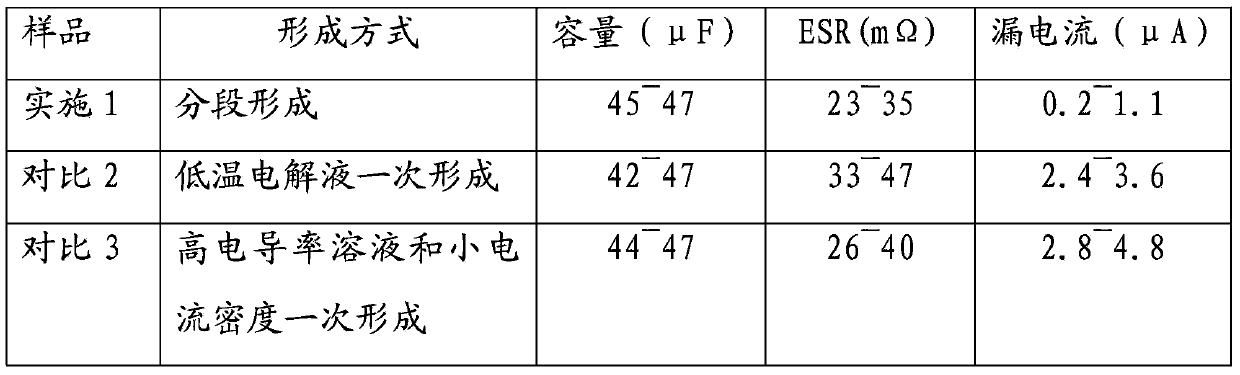

Examples

Embodiment 1

[0026] A kind of manufacture method of high-voltage electrolytic capacitor, it comprises the following steps:

[0027] (1) Carry out the molding and sintering of the valve metal anode block, press molding a tantalum block with a size of 3.1×1.0×4.3 (mm), sintering at high temperature and vacuum to volatilize the binder and effectively bond the tantalum powder, the sintering ratio Capacity is 37,000CV / g;

[0028] (2) Clean the formed anode block;

[0029] (3) Prepare an electrolyte solution with a conductivity of 10mS / cm, and then heat the electrolyte solution;

[0030] (4) Initial coating: Put the anode block in the electrolyte at 75°C, turn on the power supply to meet the rated voltage of 245V, and the initial current density is 0.5mA / g, then increase the voltage at a constant current until the oxide film formation voltage reaches the set value at the same time Constant value, every time the voltage increases by 5V, the current density doubles, and the temperature of the el...

Embodiment 2

[0053] A kind of manufacture method of high-voltage electrolytic capacitor, it comprises the following steps:

[0054] (1) Forming and sintering valve metal anode blocks;

[0055] (2) Clean the formed anode block;

[0056] (3) Prepare an electrolyte solution with a conductivity of 0.3mS / cm, and then heat the electrolyte solution;

[0057] (4) Initial coating: put the anode block in the electrolyte at 45°C, turn on the power supply to meet the rated voltage, the initial current density is 0.1A / g, and then boost the voltage at a constant current until the oxide film formation voltage reaches the set value at the same time value, that is, start constant pressure drop and keep the temperature of the electrolyte constant until a uniform and dense dielectric oxide film is formed on the surface of the anode block, and the constant pressure time is 1.5 hours;

[0058] (5) Cleaning and heat treatment of dielectric oxide film after electrochemical formation;

[0059] (6) Secondary co...

Embodiment 3

[0066] A kind of manufacture method of high-voltage electrolytic capacitor, it comprises the following steps:

[0067] (1) Forming and sintering valve metal anode blocks;

[0068] (2) Clean the formed anode block;

[0069] (3) Prepare an electrolyte solution with a conductivity of 65mS / cm, and then heat the electrolyte solution;

[0070] (4) Initial coating: put the anode block in the electrolyte at 85°C, turn on the power supply to meet the rated voltage, the initial current density is 50mA / g, and then boost the voltage at a constant current until the oxide film formation voltage reaches the set value at the same time , that is, start constant pressure drop and keep the temperature of the electrolyte constant until a uniform and dense dielectric oxide film is formed on the surface of the anode block, and the constant pressure time is 10 hours;

[0071] (5) Cleaning and heat treatment of dielectric oxide film after electrochemical formation;

[0072] (6) Secondary coating: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com