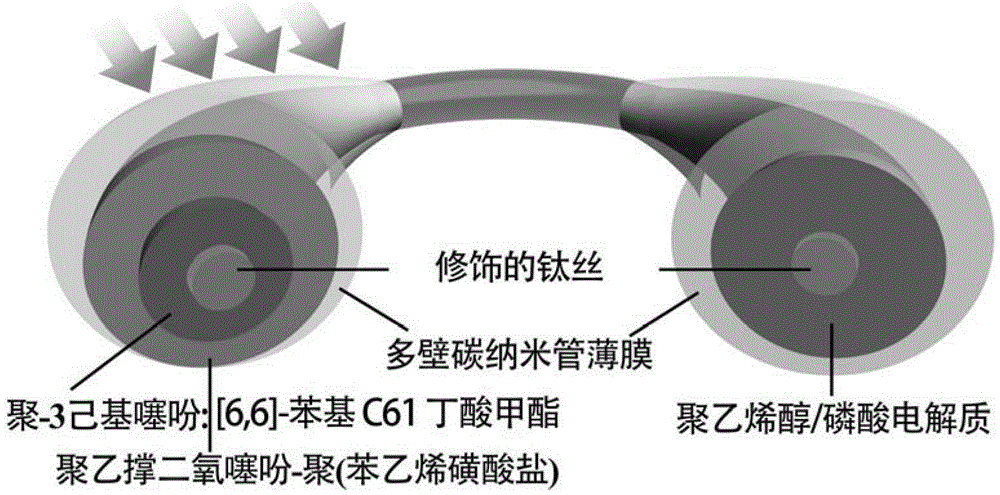

All-solid-state fibrous coaxial polymer solar cell and supercapacitor integrated device and preparation method thereof

A technology of supercapacitors and integrated devices, applied in the direction of electrolytic capacitors, hybrid capacitors, capacitors, etc., to achieve the effects of efficiency improvement, cost reduction, good transparency and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

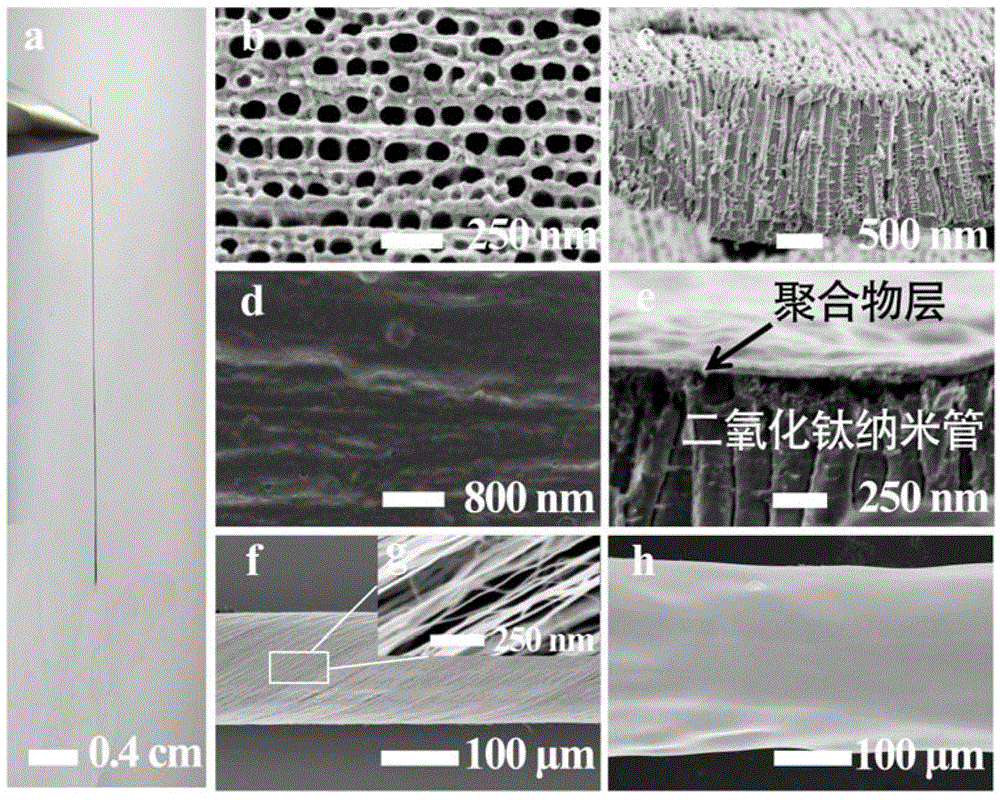

[0027] 1. Synthesis of Aligned Carbon Nanotube Arrays

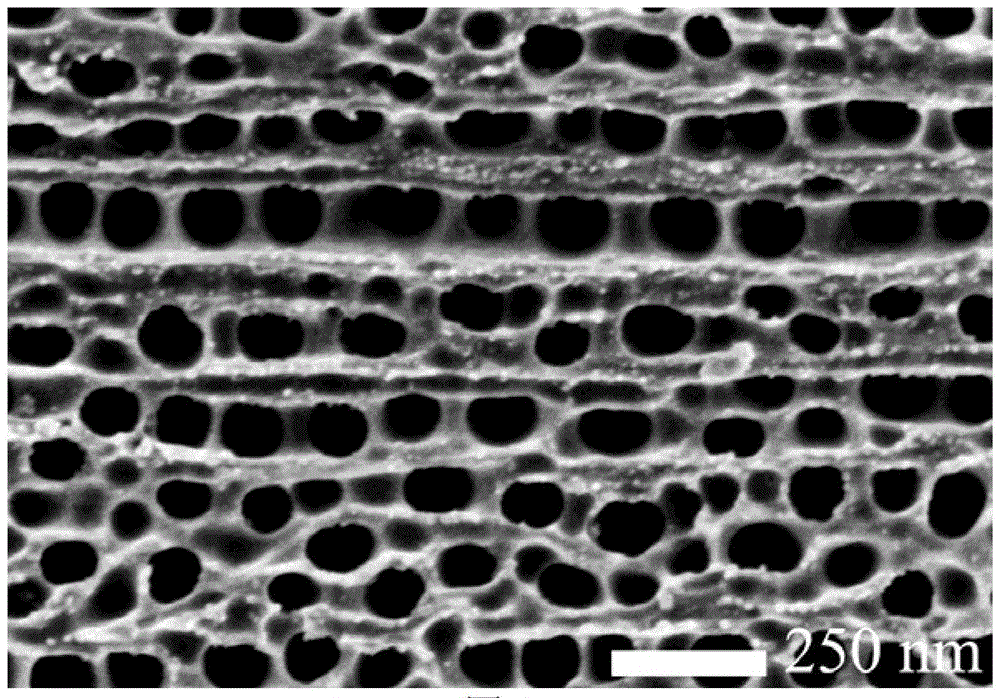

[0028] Growth of vertically spinnable multi-walled carbon nanotube arrays by chemical vapor deposition (CVD) with Fe catalyst

[0029] (1.2nm) / Al 2 o 3 (3nm) / SiO2 2 / Si,Al 2 o 3 and Fe are sequentially deposited on the silicon wafer using an electron beam evaporation coater, in which Al 2 o 3 As a buffer layer, Fe as a catalyst, ethylene as a carbon source, hydrogen and argon as carrier gases, were grown in a tube furnace at 740 °C for 10 min.

[0030] 2. Prepare the counter electrode, and pull out the aligned multi-walled carbon nanotube film on the spinnable multi-walled carbon nanotube array.

[0031] 3. Prepare the working electrode. First, use the two-electrode method to anodize the cleaned titanium wire for 10 minutes, anodize the titanium dioxide tube on the surface of the titanium wire, and then calcinate it in a tube furnace at 500 degrees Celsius for 1 hour and anneal it. After cooling down to room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com