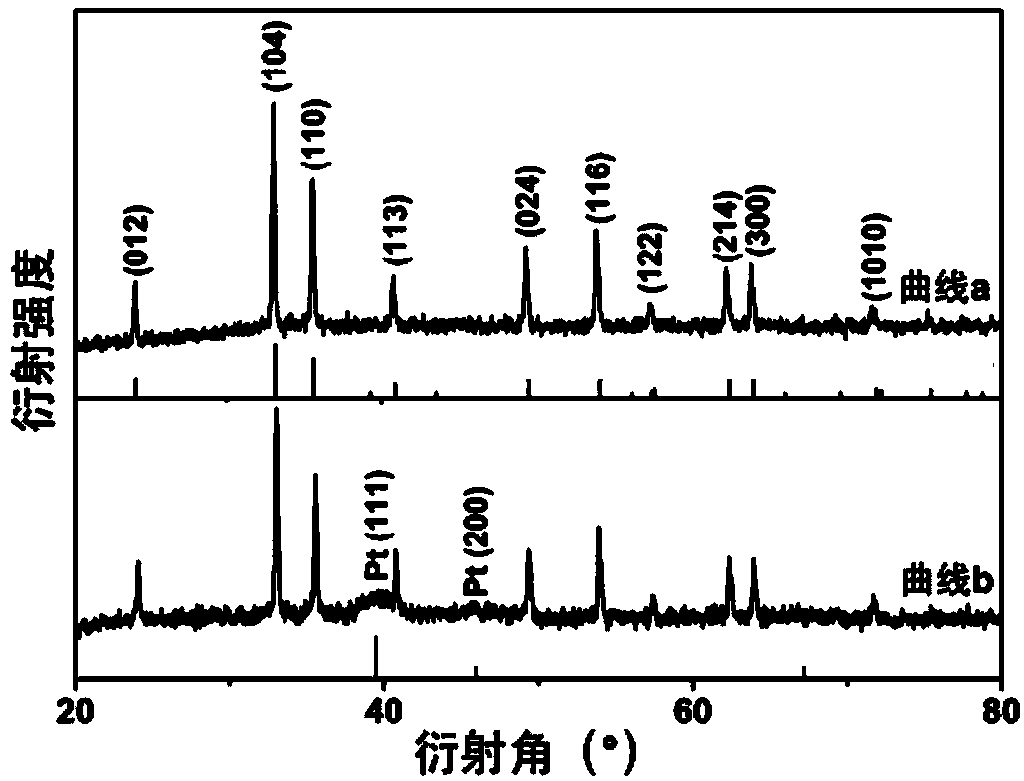

Preparation method of alpha-phase ferric oxide/platinum hybridized nanoring

A technology of ferric oxide and nano rings, which is applied in the field of composite materials, can solve the problems of high electron-hole recombination rate and short hole diffusion path, and achieve the effect of simple process, mild conditions and superior photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Prepare 40mL water-soluble ferric salt solution (ferric chloride, FeCl 3 ·6H 2 O), and adding acid phosphate (NH 4 h 2 PO 4 ) and sulfate (Na 2 SO 4 ), wherein the molar concentration of ferric chloride is 0.02mM, NH 4 h 2 PO 4 Molar concentration is 0.2mM, Na 2 SO 4 The molar concentration is 0.6mM (the molar concentration ratio of acid phosphate and sulfate is 2:6 in this embodiment, and the molar concentration ratio of ferric salt and sulfate is 1:30).

[0022] (2) Ultrasound the solution obtained in step (1) for 3-5 minutes, mix it evenly, and then transfer it to a 50mL stainless steel reaction kettle lined with polytetrafluoroethylene (the volume ratio of the reaction kettle in this example is 80%) , sealed and heated to 210 ° C for 24 hours.

[0023] (3) Cool down to room temperature naturally after the reaction is complete, centrifuge the sediment at the bottom of the kettle, wash with absolute ethanol and deionized water successively, and dry the ...

Embodiment 2

[0031] (1) Prepare 40mL water-soluble ferric salt solution (ferric chloride, FeCl 3 ·6H 2 O), and adding acid phosphate (NH 4 h 2 PO 4 ) and sulfate (Na 2 SO 4 ), wherein the molar concentration of ferric chloride is 0.02mM, NH 4 h 2 PO 4The molar concentration is 0.6mM, Na 2 SO 4 The molar concentration is 0.6mM (the molar concentration ratio of acid phosphate and sulfate is 6:6 in this embodiment, and the molar concentration ratio of ferric salt and sulfate is 1:30).

[0032] (2) Ultrasound the solution obtained in step (1) for 3-5 minutes, mix it evenly, and then transfer it to a 50mL stainless steel reaction kettle lined with polytetrafluoroethylene (the volume ratio of the reaction kettle in this example is 80%) , sealed and heated to 220 ° C for 24 hours.

[0033] (3) Same as embodiment 1.

[0034] (4) Same as embodiment 1.

[0035] (5) Immerse the powder obtained in step (4) into 40mL of ethylene glycol (in this example, the volume ratio of ethylene glycol ...

Embodiment 3

[0037] (1) Prepare 80mL water-soluble ferric salt solution (ferric nitrate, Fe(NO 3 ) 3 9H 2 O), and adding acid phosphate (NH 4 h 2 PO 4 ) and sulfate (Na 2 SO 4 ), wherein the molar concentration of ferric nitrate is 0.02mM, NH 4 h 2 PO 4 Molar concentration is 0.4mM, Na 2 SO 4 The molar concentration is 0.6mM (in this embodiment, the molar concentration ratio of acid phosphate and sulfate is 4:6, and the molar concentration ratio of ferric salt and sulfate is 1:30).

[0038] (2) Ultrasound the solution obtained in step (1) for 3 to 5 minutes, mix it evenly, and then transfer it to a 100mL stainless steel reaction kettle lined with polytetrafluoroethylene (the volume ratio of the reaction kettle in this example is 80 %), sealed and heated to 220°C for 32h.

[0039] (3) Same as embodiment 1.

[0040] (4) Prepare 2 mL of chloroplatinic acid solution (H 2 PtCl 6 ·6H 2 0, the molar concentration is 10 mM), and then add 8 mL of absolute ethanol to the chloroplatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com