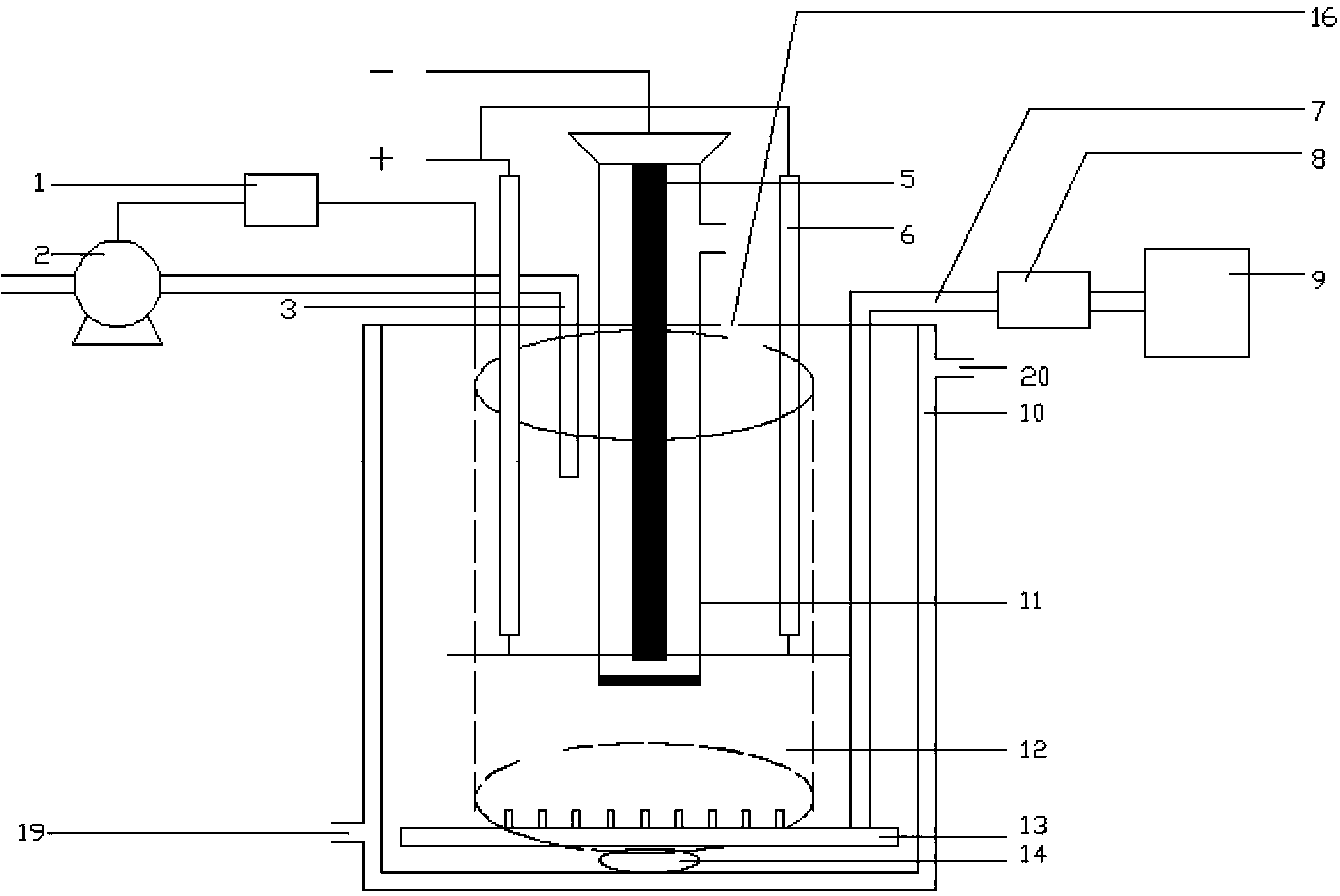

Low-temperature plasma collaborative Fenton biomembrane reaction device and implementation method thereof

A low-temperature plasma and reaction device technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Complex post-processing problems, to achieve good environmental benefits, speed up the film hanging speed, improve the effect of COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

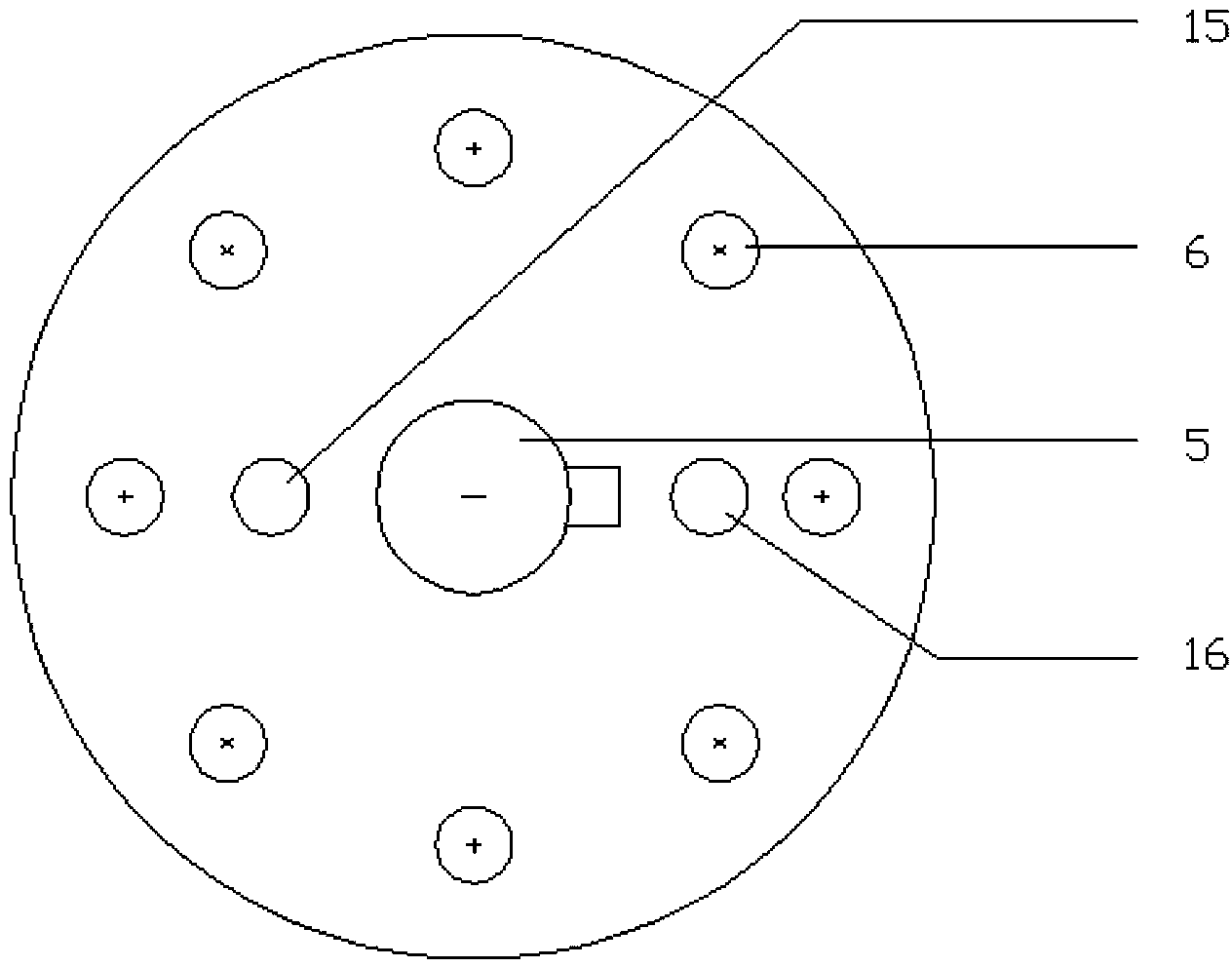

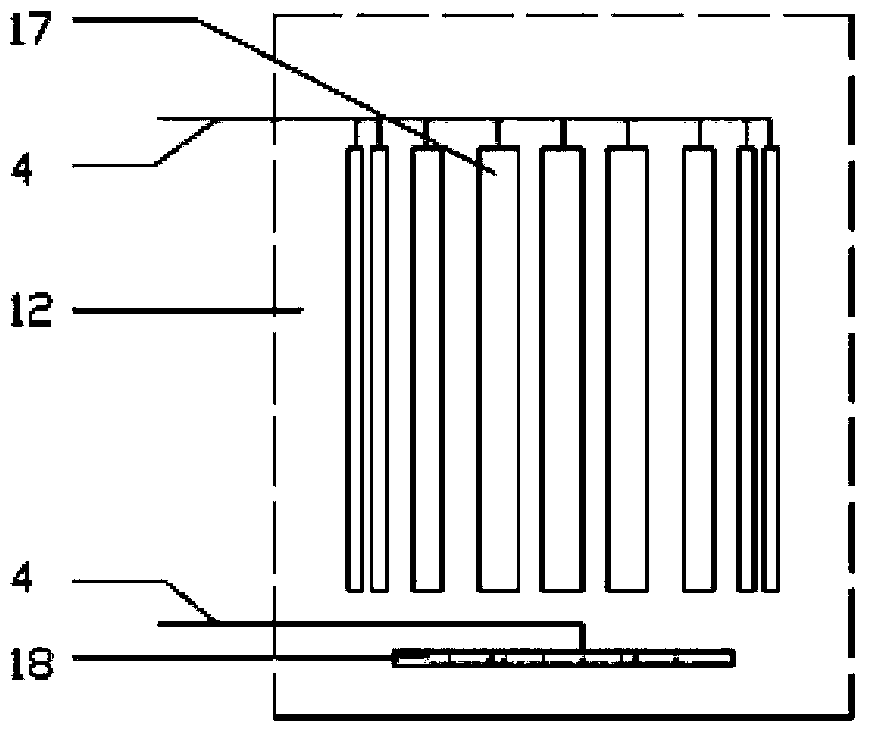

Method used

Image

Examples

Embodiment 1

[0040] (1) The activated sludge attached to the carrier was treated with low-temperature plasma Ar, and then placed in Fe(OH) 3 Formation of deposited iron in colloidal suspension;

[0041] (2) Adjust the glow current and maintain the power at 60W. Make microbial extracellular polysaccharides attach to the surface of the carrier and multiply to form a biofilm;

[0042] (3) Adjust the glow voltage to 620V, and pass the phenol simulated wastewater into the low-temperature plasma cooperative Fenton-like biofilm reaction device through the water pump;

[0043] (4) Use contact glow discharge plasma technology to degrade, and record the concentration change of hydrogen peroxide;

[0044] (5) With the degradation of pollutants, the concentration of hydrogen peroxide gradually increases. When the concentration of hydrogen peroxide reaches 2mmol / L, the pH of the wastewater is controlled to be 4;

[0045] (6) The glow voltage is 550V, and the number of anode electrodes is 2, which ar...

Embodiment 2

[0048] With other conditions unchanged, the hydrogen peroxide concentration of 2 mmol / L in step (5) in Example 1 was changed to 3 mmol / L.

Embodiment 3

[0050] With other conditions unchanged, the hydrogen peroxide concentration of 2 mmol / L in step (5) in Example 1 was changed to the hydrogen peroxide concentration of 4 mmol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com