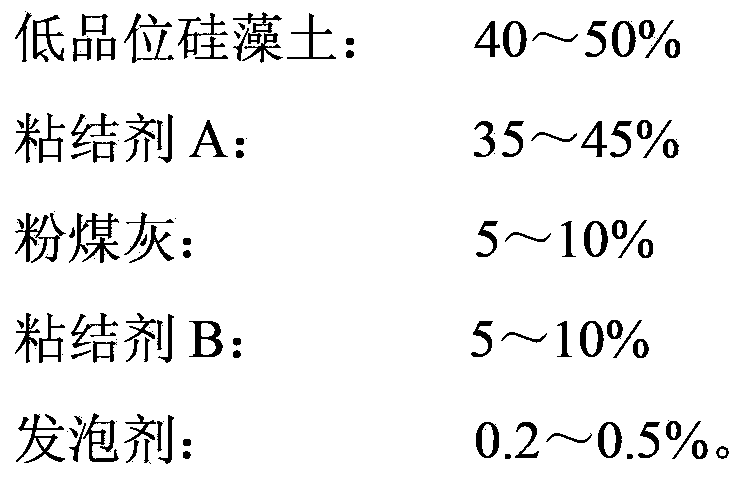

Light burning-avoiding heat-insulating material and preparation method thereof

A thermal insulation material and lightweight technology, applied in the field of building thermal insulation materials, can solve the problems of high price, poor thermal insulation effect, poor fire resistance, etc., and achieve good economic and social benefits, enhanced thermal insulation effect, and good fire performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] ①Pretreatment of raw materials: Dry, pulverize, ball mill and pass through a 40-mesh sieve for low-grade diatomite for use;

[0032] ②Ingredients: Weigh all the raw materials according to the formula (low-grade diatomite: 35g, cement: 32g, fly ash: 4.5g, latex powder: 5g, aluminum powder: 0.3g), and then weigh 76.8g of the weighed raw materials All are put into a ball mill and ball milled for 1 hour and mixed until uniform and ready for use.

[0033] ③Molding and maintenance: Pour 76.8g of the uniformly ground mixture into the container, add 76.8g of water at room temperature and stir, after stirring, put it into the mold and vibrate the mold to make the surface of the slurry smooth; after molding in the mold for 1 day, release the mold , Natural drying after curing at room temperature for 7d.

[0034] The obtained thermal insulation material has a pore size of less than 1 mm, a porosity of 45%, a compressive strength of 0.38 MPa, a flexural strength of 0.14 MPa, and a...

Embodiment 2

[0036] ① Raw material pretreatment: same as Example 1;

[0037] ②Ingredients: Weigh all the raw materials according to the formula (low-grade diatomite: 35g, cement: 30g, fly ash: 4.5g, latex powder: 6g, aluminum powder: 0.3g), and then weigh 75.8g of the weighed raw materials All are put into a ball mill and ball milled for 1.5h and mixed until uniform and ready for use.

[0038] ③Molding and maintenance: Pour 75.8g of the uniformly ground mixture into a container, add 75.8g of water to stir at room temperature, put it into the mold and shake the mold to make the surface of the slurry smooth after stirring; demold it after molding in the mold for 1 day , Natural drying after curing at room temperature for 10d.

[0039] The obtained thermal insulation material has a pore size of less than 1 mm, a porosity of 42%, a compressive strength of 0.40 MPa, a flexural strength of 0.15 MPa, and a density of 0.33 g / cm 3 , the thermal conductivity is 0.070W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com