Organic liquid fertilizer and preparation method thereof

A technology of organic liquid fertilizer and raw materials, applied in the preparation of organic fertilizer, organic fertilizer, bio-organic part treatment, etc., to achieve the effect of large processing capacity, improving crop quality and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

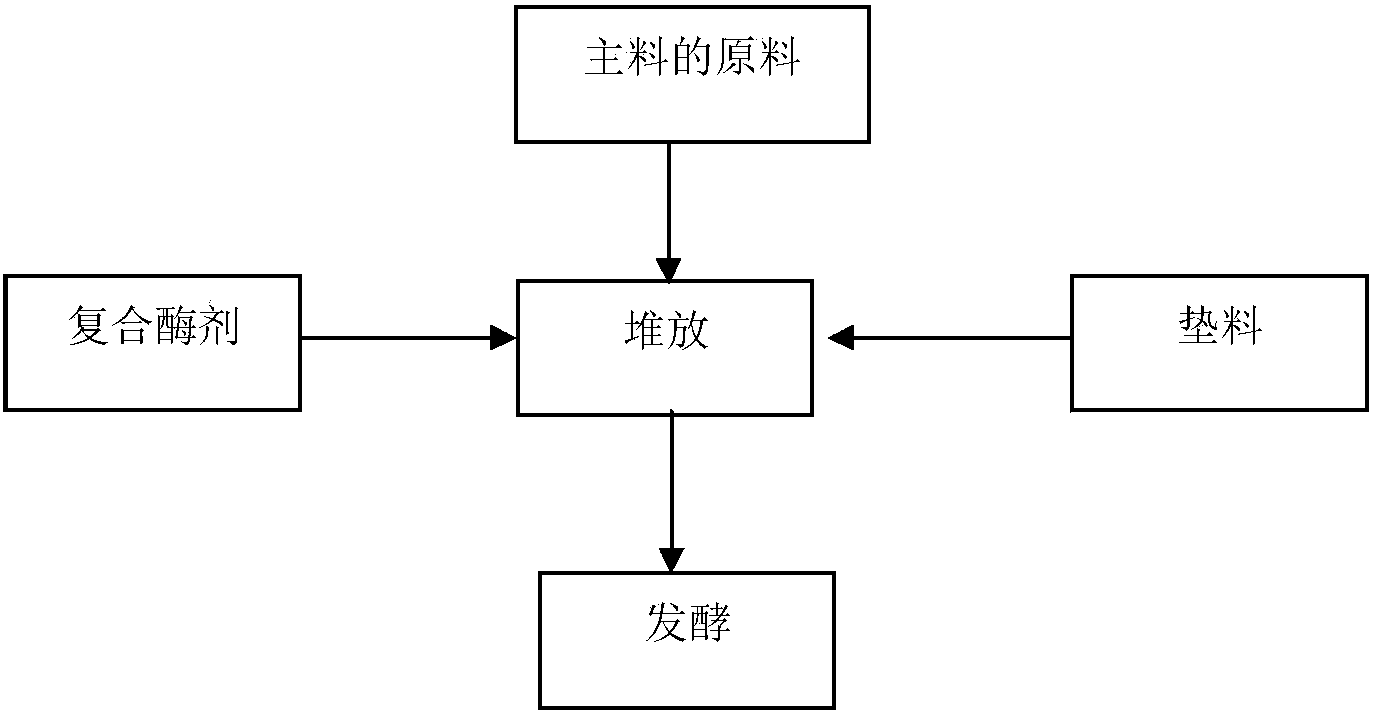

preparation example Construction

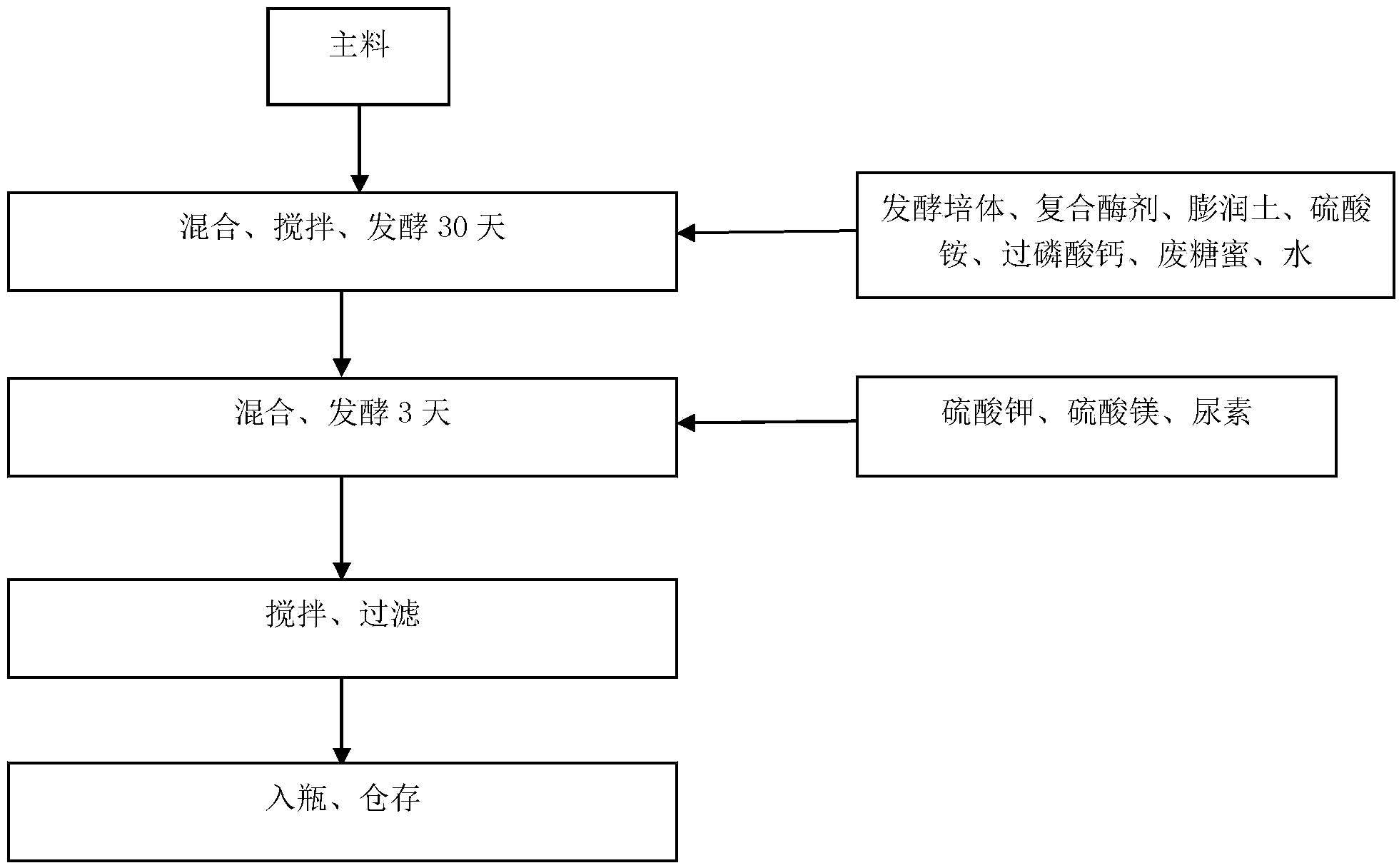

[0042] Such as figure 1 Shown, the preparation method of organic liquid fertilizer of the present invention may further comprise the steps:

[0043] 1. At room temperature (25°C), mix 200-300 parts of main ingredients, 100-200 parts of fermentation culture, 1-3 parts of compound enzyme, 50-60 parts of bentonite, and sulfuric acid in the cement fermentation tank according to the number of parts by mass. 10-25 parts of ammonium, 10-25 parts of superphosphate, 50-60 parts of waste molasses, and 300-600 parts of water are mixed. First, the waste molasses is diluted with water into waste molasses liquid, and then the main ingredients, fermentation culture, compound Enzyme, bentonite, ammonium sulfate, superphosphate, and water are added, mixed and stirred evenly, fermented for not less than 30 days, and filtered to obtain the fermentation stock solution.

[0044]2. Add 10-15 parts of potassium sulfate, 10-15 parts of magnesium sulfate, and 10-15 parts of urea to 500-600 parts of f...

Embodiment l

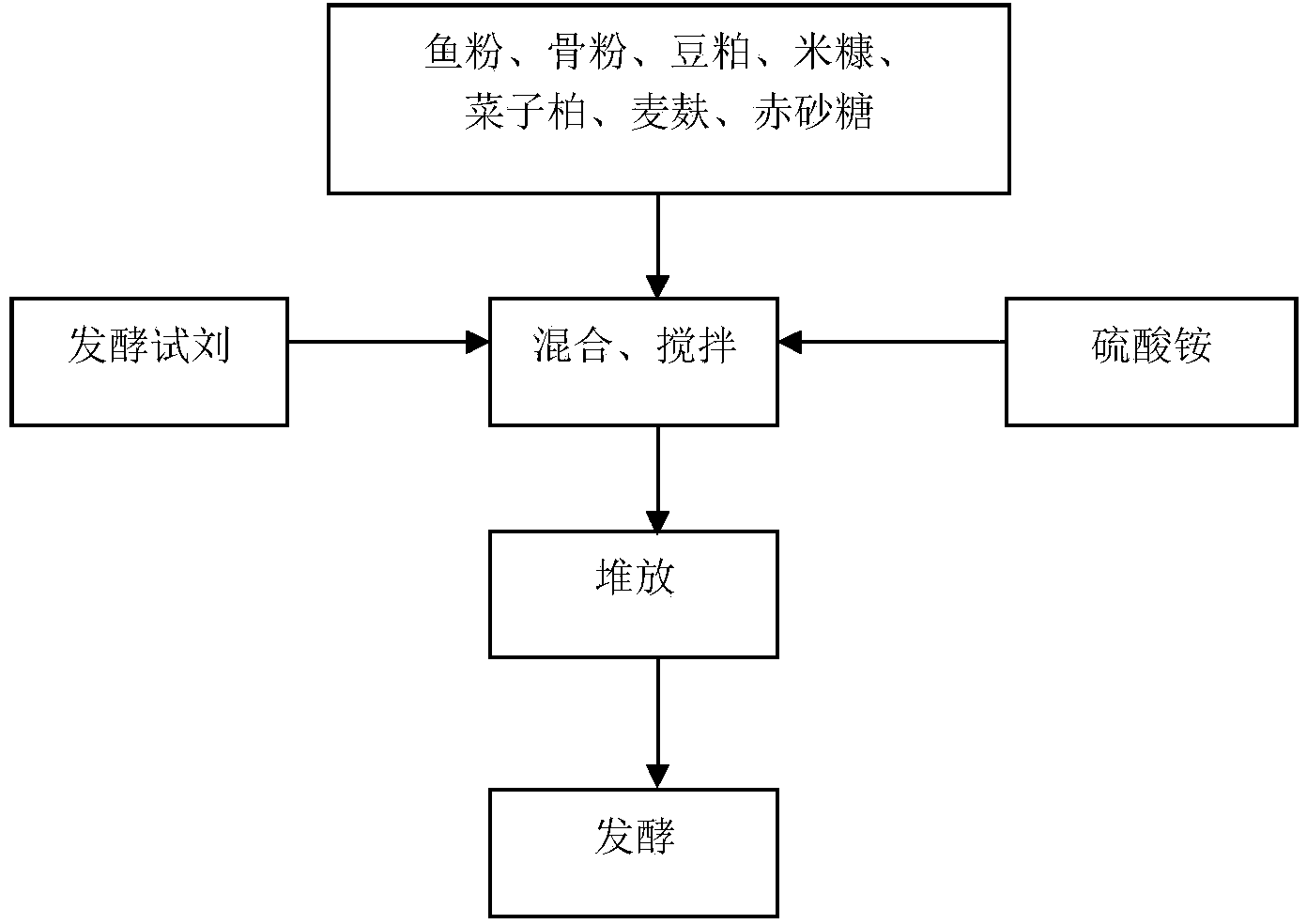

[0063] Embodiment 1, the raw material of main ingredient is 1000kg into chicken carcass, and preparation method is as follows:

[0064] 1. Mix 2000kg of rice husks with 2kg of fermentation reagent to obtain litter, and set aside.

[0065] 2. Put 30cm thick, 3m wide and 4m long litter on the indoor concrete floor, put 400kg chicken carcasses evenly on the litter, 25cm thick, add 0.2kg compound enzyme agent, sprinkle evenly on the chicken carcasses, A layer of 20cm thick bedding was spread on the corpse to form the first layer of fermentation layer.

[0066] Put 250kg of chicken carcasses evenly on the first layer of fermentation layer, 20cm thick, add 0.15kg of compound enzyme agent, sprinkle evenly on the chicken carcasses, and spread a layer of 25cm thick litter on the chicken carcasses to form the second layer. Layer fermentation layer.

[0067] Put 350kg of chicken carcasses evenly on the second layer of fermentation layer, 22cm thick, add 0.15kg of compound enzyme, sprin...

Embodiment 2

[0074] Embodiment 2, the raw material of major ingredient is 1000kg pig carcasses (10 pig carcasses, average each weight is 100kg), preparation method is as follows:

[0075] 1. Add 4kg of fermentation reagent to 2000kg of chaff, mix evenly to obtain litter, and set aside.

[0076] 2. Put a 40cm thick, 5m wide, and 5m long litter on the indoor concrete floor, place 4 pig carcasses (average weight 100kg each) evenly on the litter, 60cm thick, add 0.32kg of compound enzyme, Sprinkle evenly on the pig carcass, and then spread a layer of 30cm thick bedding on the pig carcass to form the first layer of fermentation layer.

[0077] Put 3 pig carcasses (average weight 100kg each) evenly on the first layer of fermentation layer, 30cm thick, add 0.24kg compound enzyme agent, sprinkle evenly on the pig carcasses, and spread another layer on the pig carcasses 30cm thick litter forms the second layer of fermentation layer.

[0078] Put 3 pig carcasses (the average weight of each is 100k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com