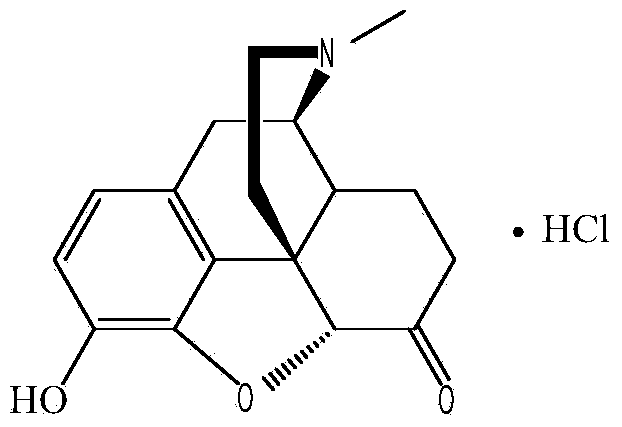

Refinement technique of hydromorphone acid salt

A technology of hydromorphone and acid salt, which is applied in the field of refining technology of hydromorphone acid salt, can solve the problems of unsatisfactory refining effect, small amount of refining, cumbersome methods, etc., and achieve the reduction of impurity content and increase of yield , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 68.5g of hydromorphone and 270mL of hydrochloric acid (hydrochloric acid (V):purified water (V)=2:3) into the salt-forming reaction bottle, stir and dissolve at 45°C. The solution was transferred to the crystallization tank. Cool down to 5°C, stir and precipitate a large amount of solids, then add 840ml of absolute ethanol and 1260L of anhydrous diethyl ether in sequence, stir and crystallize for 2 hours. Filter, mix reagents (84ml of absolute ethanol, 126ml of anhydrous ether, wash the filter cake, wash until the filtrate pH=6~7, put it in an oven and dry under reduced pressure at 45°C for 6 hours to obtain 70.0g of crude hydromorphone hydrochloride.

[0034] Add 280mL of purified water into the refined decolorization tank, raise the temperature to 35°C, then add 70.0g of crude hydromorphone hydrochloride, stir to completely dissolve, add 2g of medicinal charcoal, and then add about 0.15mL of dilute hydrochloric acid (hydrochloric acid (V): Purified water (V) = 1:...

Embodiment 2

[0036] Add 60.0g of hydromorphone and 200mL of dilute hydrochloric acid (hydrochloric acid (V):purified water (V)=2:3) into the reaction flask, stir and dissolve at 40°C. The solution was transferred to the crystallization tank. Cool down to -5°C, stir to precipitate a large amount of solids, add 440ml of absolute ethanol and 440ml of anhydrous isopropyl ether in sequence, stir and crystallize for 1 hour. Filter, wash the filter cake with a mixed reagent (40ml of absolute ethanol, 60ml of anhydrous isopropyl ether), wash until the filtrate pH=6~7, put it in an oven and dry under reduced pressure at 42°C for 6 hours to obtain crude hydromorphone hydrochloride 63.5 g.

[0037] Add 180mL of purified water into the refined decolorization tank, raise the temperature to 40°C, then add 63.5g of crude hydromorphone hydrochloride, stir to completely dissolve, add 1.5g of medicinal charcoal, and then add about 0.10mL of dilute hydrochloric acid (hydrochloric acid (V) : Purified water ...

Embodiment 3

[0039]Add 70.0g of hydromorphone and 230mL of dilute hydrobromic acid (hydrobromic acid (V):purified water (V)=2:3) into the salt-forming reaction bottle, stir and dissolve at 45°C. The solution was transferred to the crystallization tank. Cool down to 10°C, stir and precipitate a large amount of solids, then add 840ml of absolute ethanol and 840ml of ethyl ether in turn, and stir for 1.5 hours to crystallize. Filter, wash the filter cake with a mixed reagent (70ml of absolute ethanol, 210ml of absolute ether), wash until the filtrate pH=6~7, put it in an oven and dry under reduced pressure at 45°C for 6 hours to obtain crude hydromorphone hydrobromide 72.0 g.

[0040] Add 280mL of purified water into the refined decolorization tank, raise the temperature to 40°C, then add 72g of crude hydromorphone hydrobromide, stir to completely dissolve, add 1.5g of medicinal charcoal, and then add about 0.20mL of dilute hydrobromic acid (hydrogen Bromic acid (V): purified water (V) = 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com