Precious-metal-carried mesoporous composite oxide catalyst and preparation method and application thereof

A technology of composite oxides and noble metals, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, molecular sieve catalysts, etc. and stability limitations, etc., to achieve the effects of easy operation and control, improved CO catalytic performance, high acidity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of a noble metal supported catalyst and its application in CO catalytic oxidation reaction.

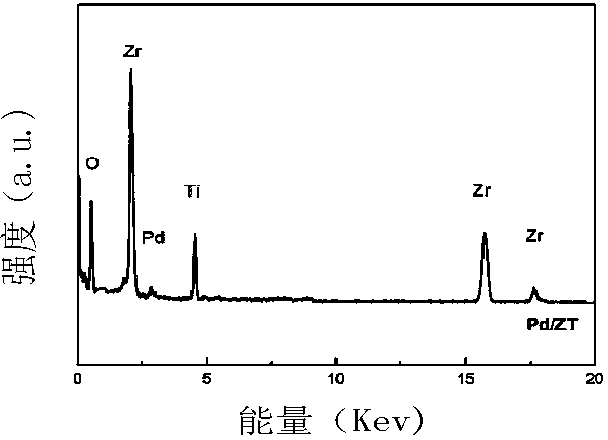

[0029] The supported catalyst is a mesoporous composite oxide doped with noble metal ions (zirconia titanium oxide, ZrO 2 -TiO) material, this noble metal ion is located in the framework of mesoporous zirconia-titanium, for example, compounded on the framework of mesoporous zirconia-titanium by in-situ composite.

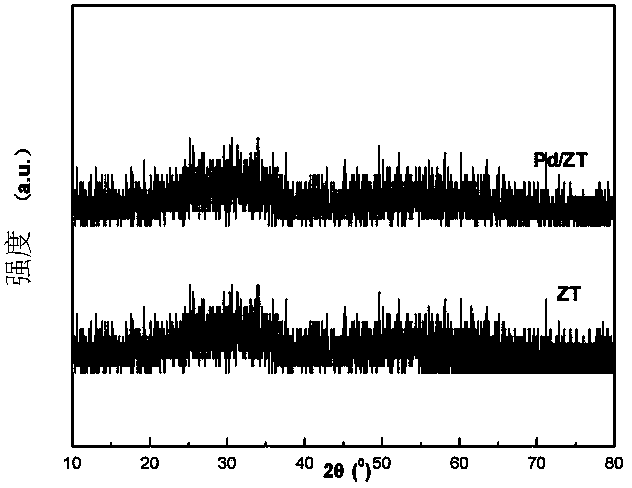

[0030] Mesoporous composite oxides (zirconia titanium, ZrO 2 -TiO) has a Zr / Ti ratio of 7:3. In a preferred example, the Zr / Ti ratio is 7:3. Supported mesoporous composite oxides (zirconia-titanium, ZrO 2 -TiO) may have an amorphous structure.

[0031] Catalytically active component noble metals such as Pd are also preferably present in amorphous form.

[0032] In the present invention, the noble metal X accounts for 0.5-1.5 wt% of the total weight of the catalyst. Preferably 1 wt%.

[0033] Preparation method: Novel...

Embodiment 1

[0050] Preparation of catalyst Pd / ZT: Add 5ml of concentrated hydrochloric acid to 10ml of water and stir for 0.5h, then add 0.043~0.128g of PdCl 2 powder, then add 15ml of zirconium n-propoxide (70%) and 5ml of tetrabutyl titanate to hydrochloric acid solution for prehydrolysis for 1 hour; add 5.47g of tetrapropylammonium hydroxide and 3.1g of copper nitrate to 90ml of aqueous solution Stir at room temperature for 2h. Mix the above two solutions together and stir for 2 hours, then put them into a hydrothermal kettle for crystallization at 120°C for 48 hours, dry the crystallized product in an oven at 100°C, and calcinate the obtained powder in a muffle furnace at 400°C for 4 hours , with a heating rate of 1°C min -1 . The resulting material is Pd-loaded mesoporous ZT, denoted as Pd / ZT.

[0051] figure 1 Contains the XRD diffraction spectrum of the catalyst Pd / ZT prepared in this embodiment. Pd / ZT maintains the amorphous structure characteristics of the carrier ZT.

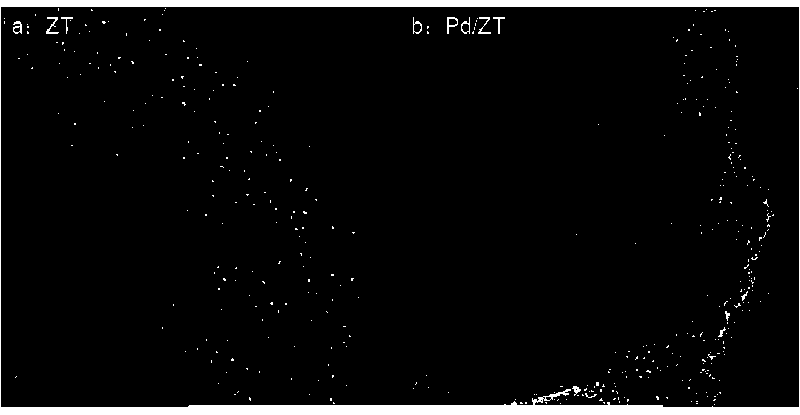

[00...

Embodiment 2

[0056] The difference between this example and Example 1 is that there is no Pd doping, only the catalyst carrier ZT, and other contents are the same as those described in Example 1: 5ml of concentrated hydrochloric acid is added to 10ml of water and stirred for 0.5h, and 15ml of Zirconium n-propoxide (70%) and 5ml tetrabutyl titanate were added to hydrochloric acid solution for prehydrolysis for 1 hour; 5.47g tetrapropylammonium hydroxide and 3.1g copper nitrate were added to 90ml aqueous solution and stirred at room temperature for 2 hours. Mix the above two solutions together and stir for 2 hours, then put them into a hydrothermal kettle for crystallization at 120°C for 48 hours, dry the crystallized product in an oven at 100°C, and calcinate the obtained powder in a muffle furnace at 400°C for 4 hours , with a heating rate of 1°C min -1 . The resulting material is mesoporous ZT, denoted as ZT.

[0057] It has been detected that the catalyst carrier ZT prepared in this ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com