Method for preparing Enramycin A and B hydrochloride mixture

A technology of enramycin and hydrochloride, applied in the field of preparing enramycin A and B hydrochloride mixture, can solve the problems of large-scale production limitation, cumbersome weak acid resin regeneration, high solvent usage, and achieves The effect of long resin life, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

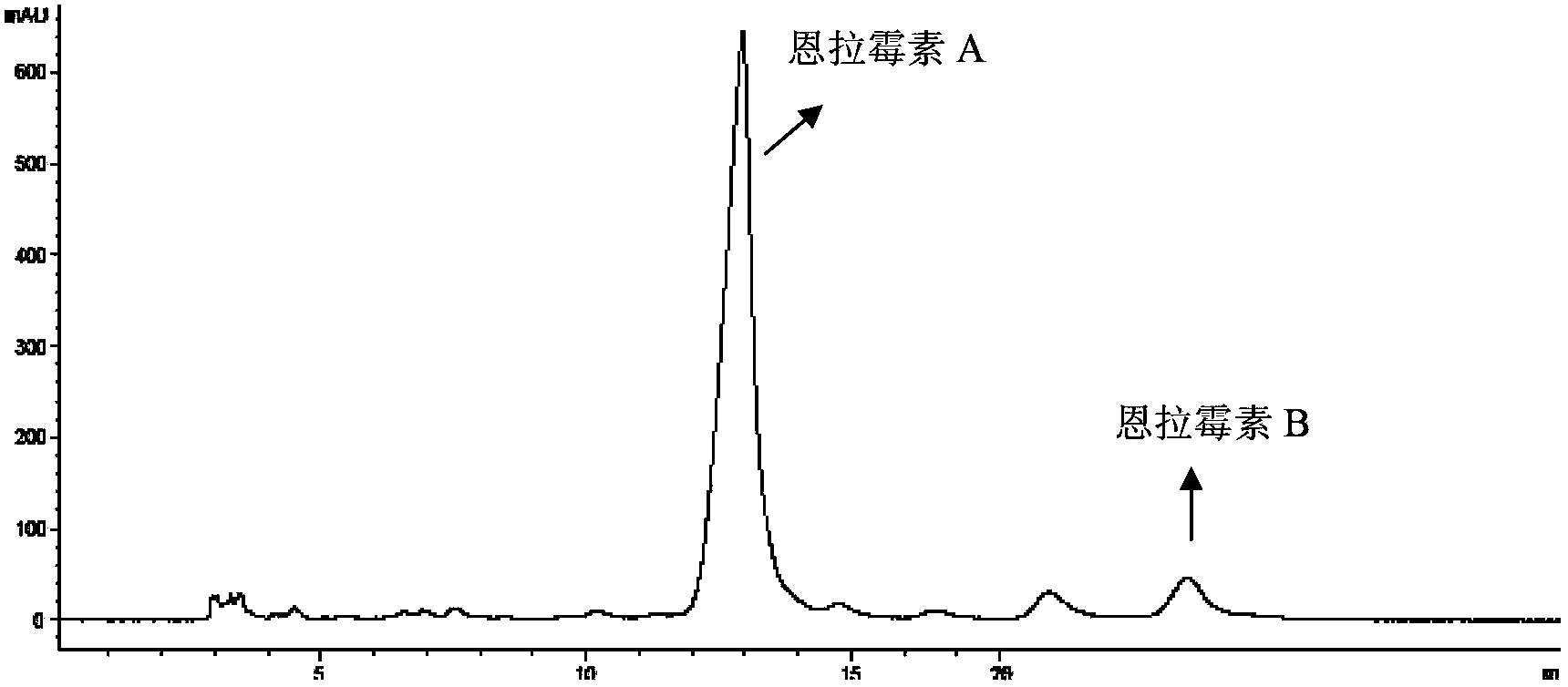

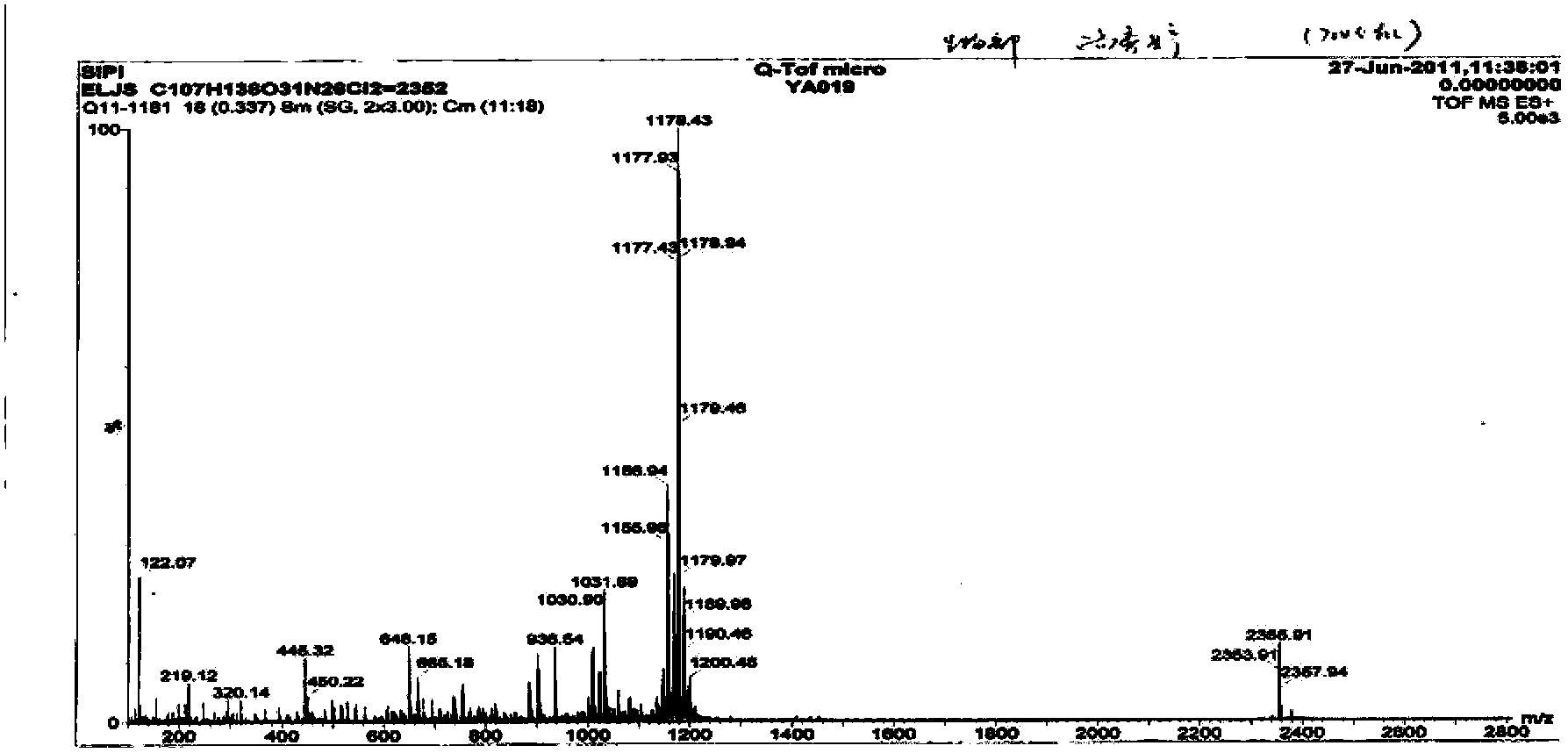

[0054] 1L enramycin fermented liquid is filtered, obtain the mycelium that contains enramycin, weigh 42g, be 2.0 (with hydrochloric acid to adjust pH) aqueous solution (extract solution) that mycelium contains 50% methanol ) in 200ml, then perform ultrasonic cell disruption for 1h and mechanically stir for 12h, filter after standing, add 100ml of the above extract to the mycelium filter residue, filter after ultrasonic stirring, mix the two filtrates and vacuum at 35°C Concentrate to 30ml to obtain a concentrated solution containing enramycin A and B.

[0055] Install a chromatographic column with a height of 16cm and a diameter of 4cm containing macroporous adsorption resin HZ-816, and regenerate the equilibrium completely. Adjust the pH of the above concentrated solution to 8.0, add 30ml of 50% methanol and filter, put the filtrate on the column at a speed of 50ml / h, and then wash 2CV and 3CV with 20% and 80% aqueous methanol to remove impurities; 60% methanol with pH 2.0 (...

Embodiment 2

[0057] 1L enramycin fermented liquid is filtered, obtain the mycelium that contains enramycin, weighing 52g, the aqueous solution (extract solution) that contains 84% methanol pH is 4.0 (with hydrochloric acid to adjust pH) with mycelium ) in 300ml, then ultrasonically disrupted cells for 1.5h and mechanically stirred for 24h, filtered after standing, and concentrated under reduced pressure and vacuum at 40°C to 20ml to obtain a concentrated solution containing enramycin A and B.

[0058] Install a chromatographic column with a height of 20cm and a diameter of 4cm containing macroporous adsorption resin HZ-818, and regenerate the equilibrium completely. Adjust the pH of the above-mentioned concentrated solution to 9.0, add 20ml of 84% methanol and filter, put the filtrate on the column at a speed of 50ml / h, and then wash 2CV and 3CV with 40% and 70% methanol aqueous solution to remove impurities; The aqueous solution of 90% methanol with a pH of 3.0 (adjusted with hydrochlor...

Embodiment 3

[0060] 1L enramycin fermented liquid is filtered, obtain the mycelium that contains enramycin, weigh 48g, be 3.0 (with hydrochloric acid to adjust pH) aqueous solution (extract solution) that mycelium contains 75% methanol ) in 300ml, then subjected to ultrasonic cell disruption for 2h and mechanical stirring for 18h, filtered after standing, and concentrated under reduced pressure and vacuum at 40°C to 10ml to obtain a concentrated solution containing enramycin A and B.

[0061] Install a chromatographic column with a height of 25cm and a diameter of 4cm containing macroporous adsorption resin HZ-803, and regenerate the equilibrium completely. Adjust the pH of the above concentrate to 8.5, add 10ml of 75% methanol and filter it, put the filtrate on the column at a speed of 50ml / h, then wash 2CV and 3CV with 40% and 70% aqueous methanol to remove impurities; 80% methanol with a pH of 2.5 (adjust the pH with hydrochloric acid) was eluted, and the eluate was collected step by st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com