Reclaiming agent, reclaimed rubber prepared therefrom, and preparation method of reclaimed rubber

A technology for reclaimed rubber and rejuvenating agent, applied in recycling technology, plastic recycling, etc., can solve the problems of large Mooney viscosity rebound, difficult to promote, too expensive, etc., achieve small regeneration process, improve operating environment and processing technology Simple and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 50 kilograms of 20-40 mesh waste tire rubber powder into a 200-liter high-speed mixer, add a composite environmental protection regeneration activator as 250 grams of Pitong-22, 5 kilograms of stearic acid, 100 grams of accelerator D, and 100 grams of Antioxidant BHT, a mixture of 100 grams of manganese dioxide, 6 kilograms of environmentally friendly aromatic oil, a mixture of 250 grams of rosin and 5 kilograms of light calcium carbonate as a processing aid, stirred in a high-speed mixer for 8-12 minutes, and then mixed at a high speed The material in the machine will be discharged when the temperature rises to 120°C due to friction. Put the mixed primary mixture into a mill or extruder, and after 5-8 minutes of pressing, it will become a uniform sheet and become recycled rubber.

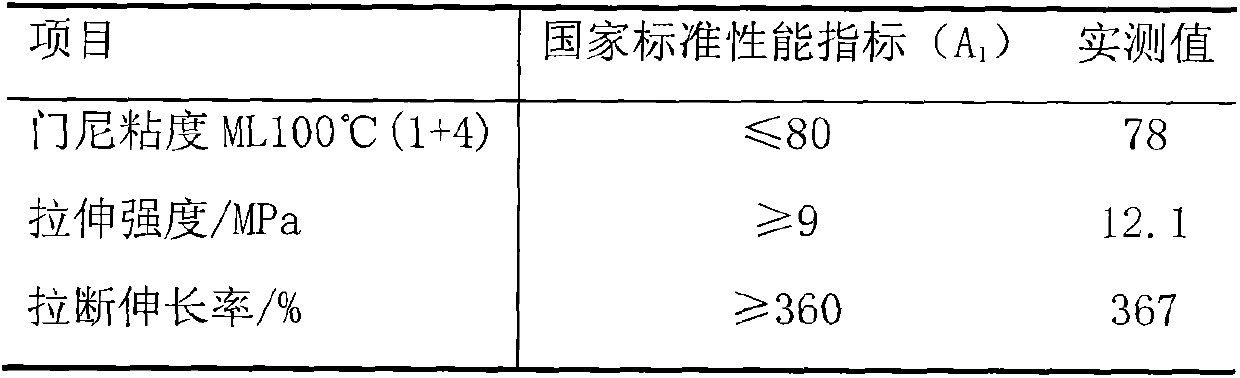

[0026] According to the national standard GB / T13460-2008, the performance of the regenerated rubber is tested to obtain that the basic performance of the regenerated rubber in this examp...

Embodiment 2

[0029] Add 50 kg of 20-40 mesh waste tire rubber powder into a 200-liter high-speed mixer, add a compound environmental protection regeneration activator as 250 g of Pitong-22, 5 kg of stearic acid, 100 g of urea, and 100 g of antioxidant Agent BHT, the mixture of 100 grams of manganese dioxide, 6 kilograms of plant asphalt, processing aid is the mixture of 250 grams of coumarone resin, 4 kilograms of light calcium carbonate, 1 kilogram of white carbon black, stir 8- After 12 minutes, the temperature of the material in the high-speed mixer is raised to 120°C due to friction, and the material can be discharged. Put the mixed primary mixture into a mill or extruder, and after 5-8 minutes of pressing, it will become a uniform sheet and become recycled rubber.

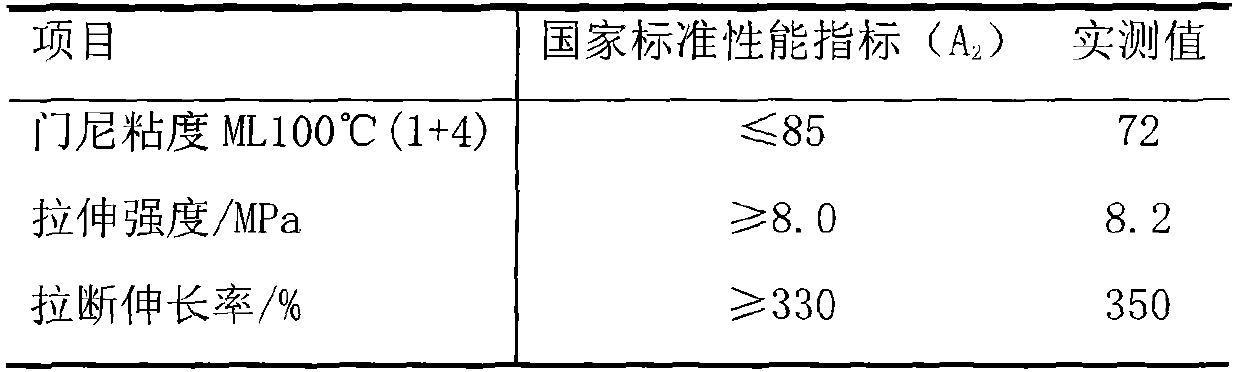

[0030] According to the national standard GB / T13460-2008, the performance of the regenerated rubber is tested to obtain that the basic performance of the regenerated rubber in this example meets the national A2 standard fo...

Embodiment 3

[0033] Add 50 kilograms of 20-40 mesh waste tire rubber powder into a 200-liter high-speed mixer, add a composite environmental protection regeneration activator as 250 grams of Pitong-22, 5 kilograms of stearic acid, 100 grams of accelerator D, and 100 grams of Antioxidant BHT, a mixture of 100 grams of manganese dioxide, 6 kilograms of pine tar, a mixture of 250 grams of rosin, 4 kilograms of light calcium carbonate, and 0.5 kilograms of carbon black as processing aids, stirred in a high-speed mixer for 8-12 minutes Finally, the material in the high-speed mixer is heated up to 120°C due to friction, and then the material can be discharged. Put the mixed primary mixture into a mill or extruder, and after 5-8 minutes of pressing, it will become a uniform sheet and become recycled rubber.

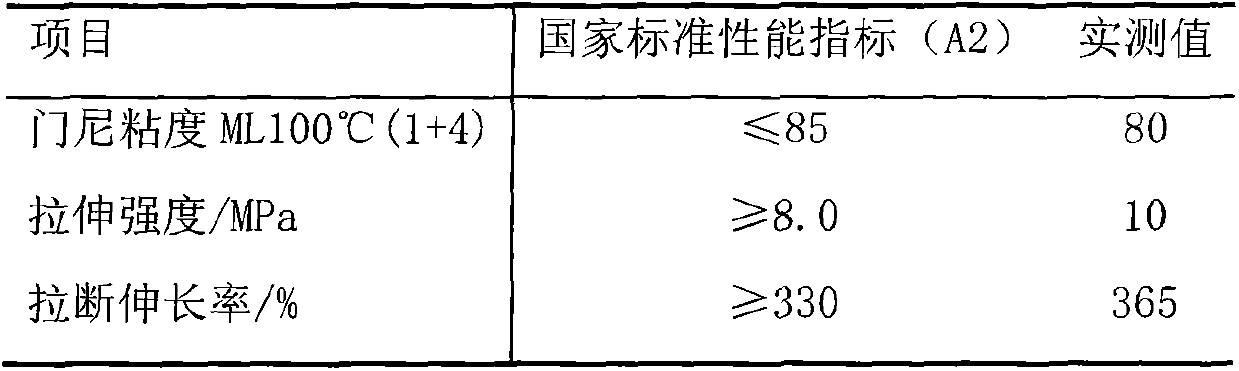

[0034] According to the national standard GB / T13460-2008, the performance of the regenerated rubber is tested to obtain that the basic performance of the regenerated rubber in this example m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com