Preparation method of tubular starch derivative

A technology of starch derivatives and starch, which is applied in the field of modified starch processing, can solve the problems of low efficiency of debranching enzyme debranching starch, wide range of polymers of tubular starch derivatives, and reduced yield of tubular starch derivatives, so as to improve the yield , Strong embedding ability and narrow distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Disperse 5g of glutinous rice starch in 100mL of distilled water, stir, put in a boiling water bath until the starch is completely gelatinized, and cool to room temperature; in the JY92-2D ultrasonic cell breaker, immerse the ultrasonic probe in the starch paste, and at an ultrasonic frequency of 20kHz, ultrasonic The power is 200W, and the ultrasonic treatment time is 15min in the way of ultrasonication for 3s and rest for 3s; cool to 37°C, adjust the pH to 3.5 with 0.1mol / L acetic acid-sodium acetate buffer solution, add 5mL isoamylase (enzyme activity 5U / mL ) for 12 hours, heated in a boiling water bath for 5 minutes to stop the reaction, and cooled to room temperature.

[0022] Take 10mL of starch debranching solution, under stirring at a rate of 50rpm, add 10mL of ethanol at a rate of 0.16mL / min through a peristaltic pump to make the volume ratio of aqueous solution to ethanol 1:1, continue to stir for 10min, stand still at 4°C for 12h, and Centrifuge at 10,000×g f...

Embodiment 2

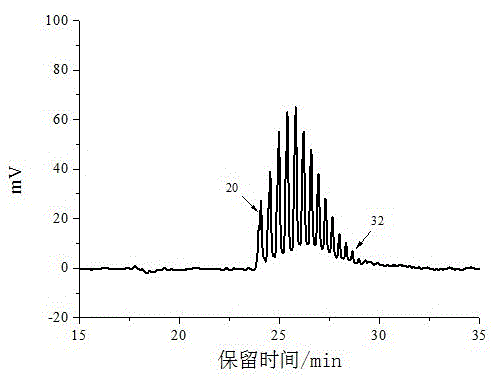

[0024] The starch derivatives prepared in Example 1 were dissolved in distilled water and analyzed by high performance anion chromatography. Analysis conditions: adopt Dionex ICS-500 chromatographic system, column type is DionexCarboPAC PA200 (250*4mm I.D.); eluent: 100mM sodium hydroxide solution (solution A), 100mM sodium hydroxide solution containing 600mM sodium acetate (solution B); Gradient elution: 20% eluent B at 0 min, 100% eluent B at 60 min; the flow rate is 1 mL / min, the injection volume is 25 μL, see figure 2 , figure 2 It shows that the degree of polymerization of the obtained tubular starch derivative is 20-32.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com