Non-phosphorus composite corrosion and scale inhibitor suitable for industrial circulating cooling water

A corrosion and scale inhibitor, circulating cooling water technology, applied in the direction of descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems such as sodium molybdate hindering the promotion, and achieve scale inhibition The formation, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Select raw materials by weight percentage

[0023] Naphthalene Sulfonate Sodium Formaldehyde Condensate (SNF) 45%,

[0024] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer (AA / AMPS) 5%,

[0025] Polyepoxysuccinic Acid (PESA) 10%,

[0026] Zinc salt (ZnSO 4 ·7H 2 O) 9.5%,

[0027] Benzotriazole (BTA) 0.7%,

[0028] The rest is water.

[0029] Add water, sodium naphthalenesulfonate formaldehyde condensate, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, polyepoxysuccinic acid, zinc salt and azole compounds into the container in sequence. After stirring for 2 hours, a phosphorus-free composite corrosion and scale inhibitor was obtained.

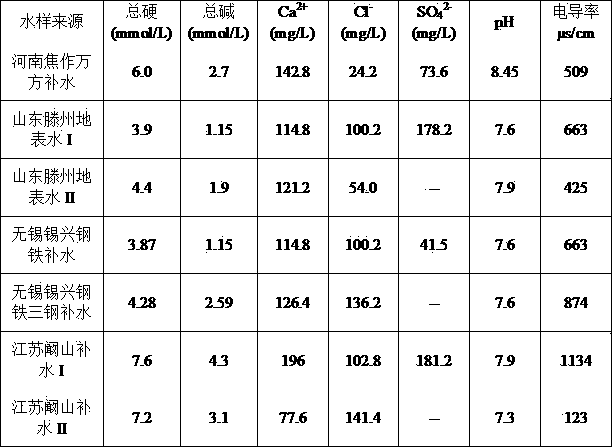

[0030] The above-mentioned non-phosphorus corrosion and scale inhibitor formula 1 was applied to water replenishment in Wanfang, Jiaozuo, Henan in Table 1, and corrosion and scale inhibition experiments were carried out.

Embodiment 2

[0032] Select raw materials by weight percentage

[0033] Sodium naphthalenesulfonate formaldehyde condensate (SNF) 28%,

[0034] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer (AA / AMPS) 15%,

[0035] Polyepoxysuccinic Acid (PESA) 10%,

[0036] Zinc salt (ZnSO 4 ·7H 2 O) 11%,

[0037] Benzotriazole (BTA) 0.5%,

[0038] The rest is water.

[0039] Add water, sodium naphthalenesulfonate formaldehyde condensate, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, polyepoxysuccinic acid, zinc salt and azole compounds into the container in sequence. After stirring for 1 hour, a phosphorus-free composite corrosion and scale inhibitor was obtained.

[0040] The above-mentioned non-phosphorus corrosion and scale inhibitor formula 2 was applied to the surface water I in Tengzhou, Shandong in Table 1, and the corrosion and scale inhibition experiments were carried out.

Embodiment 3

[0042] Select raw materials by weight percentage

[0043] Naphthalene Sulfonate Sodium Formaldehyde Condensate (SNF) 27%,

[0044] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer (AA / AMPS) 6%,

[0045] Polyepoxysuccinic Acid (PESA) 20%,

[0046] Zinc salt (ZnSO 4 ·7H 2 O) 8%,

[0047] Benzotriazole (BTA) 1.0%,

[0048] The rest is water.

[0049] Add water, sodium naphthalenesulfonate formaldehyde condensate, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, polyepoxysuccinic acid, zinc salt and azole compounds into the container in sequence. After stirring for 1.5 hours, the phosphorus-free re-corrosion and scale inhibitor was obtained.

[0050] The above formula 3 of a phosphorus-free corrosion and scale inhibitor was applied to the surface water II in Tengzhou, Shandong Province in Table 1, and the corrosion and scale inhibition experiments were carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com