Urease inhibitor composition

A technology of urease inhibitor and composition, which is applied in the field of urease inhibitor composition and urease inhibitor composition with gossypol as active substance, and achieves the effect of not being easy to preserve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of Urease Inhibitors

[0037] Instrument: WGZ-2XJ bacterial turbidimeter (instrument) (Shanghai Xinrui Instrument Co., Ltd.), HH-2 digital display constant temperature water bath (Changzhou Aohua Instrument Co., Ltd.), DHG 9070A electric heating constant temperature blast drying oven ( Shanghai Jinghong Experimental Equipment Co., Ltd.)

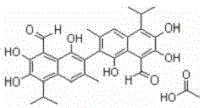

[0038] Reagents: gossypol acetate (≥98.0%, Shaanxi Ciyuan Biotechnology Co., Ltd.), PVP (K15), PVP (K25), PVP (K30) (Aladdin Reagent (Shanghai) Co., Ltd.), dichloromethane (Sinopharm Group Chemical Reagent Co., Ltd.), absolute ethanol (Nanjing Chemical Reagent Co., Ltd.), urea (Guangdong Guanghua Chemical Factory Co., Ltd.), urease (activity>4U / mg, Shanghai Jinsui Biotechnology Co., Ltd.). All reagents used in the experiment were of analytical grade.

[0039] The following are some embodiments of the present invention:

[0040] Inhibitor 1 The preparation process:

[0041] S1. Accurately weigh the solids ...

Embodiment 2

[0077] Example 2 Performance testing of inhibitors

[0078] 1. Dispersion experiment of urease inhibitor composition in water, detection of sedimentation performance

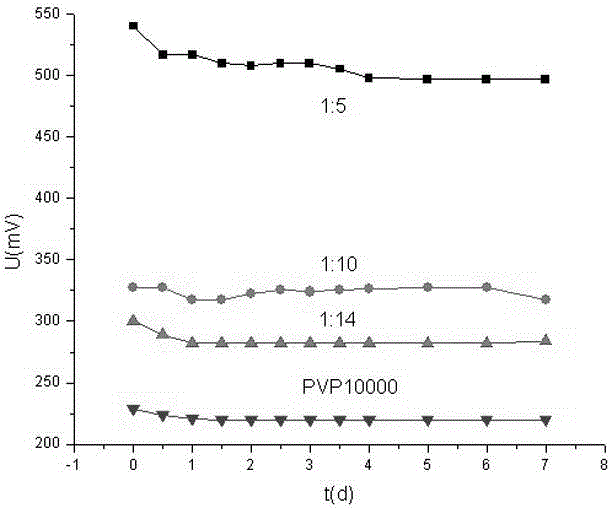

[0079] Take 0.01g of samples (inhibitors 1-9 prepared in Example 1) in a beaker, add 5mL of distilled water, ultrasonically disperse until the solution is clear, and then transfer all the samples to the sample bottle. After the bacterial turbidity meter is preheated for 30 minutes, perform zero adjustment and calibration, put it into the sample bottle filled with liquid, read the turbidity value (in MCF) and the corresponding voltage value (in mV) at regular intervals, and draw the graph . The sedimentation curve of gossypol acetate dispersion is shown in the appendix figure 1 shown. attached by figure 1 It can be seen that within 0 to 7 days, the analysis of the turbidity and its corresponding voltage data shows that PVP basically has no effect on the change of the turbidity of the dispersion. In the PVP...

Embodiment 3

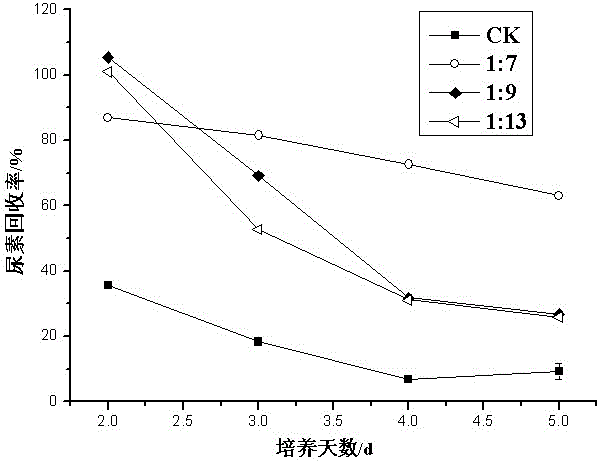

[0080] Example 3 Urease inhibitory performance test of urease inhibitor composition

[0081] 1. Preparation of urease solution Accurately weigh 0.0190 g of urease, dissolve it in distilled water in a beaker, transfer the solution to a 25 mL volumetric flask, dilute to volume, and filter. Pipette 20 mL of the filtrate into a 100 mL volumetric flask, and distilled water to volume.

[0082] 2. Preparation of reaction solution In each 50 mL volumetric flask, add different concentrations of inhibitor solution and 3 mL urease solution, and place the volumetric flask in a water bath at 37 °C for pre-incubation. After 1 h, add a little pH7.0 phosphate buffer solution and 1 mL of 10% urea to the volumetric flask, and adjust the phosphate buffer solution to volume, and place it in a water bath at 37 °C for 0.5 h.

[0083] 3. Detection method With no urea added as a reference, it is determined by indophenol blue spectrophotometry. Take 2 mL of the solution from each volumetric flask ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com