Method for rapidly preparing forsythin from forsythia suspense leaves

A technology for forsythia leaves and forsythin, which is applied in the field of rapidly preparing forsythin from forsythia leaves, can solve the problems of low purity, long time consumption, cumbersome methods and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Take forsythia leaves, crush them, and pass through a 10-20 mesh sieve to obtain powder;

[0032] 2) Weigh 200g of forsythia leaf powder, add 2000mL of absolute ethanol to extract by back distillation, extract twice, filter with three layers of gauze, and obtain the filtrate;

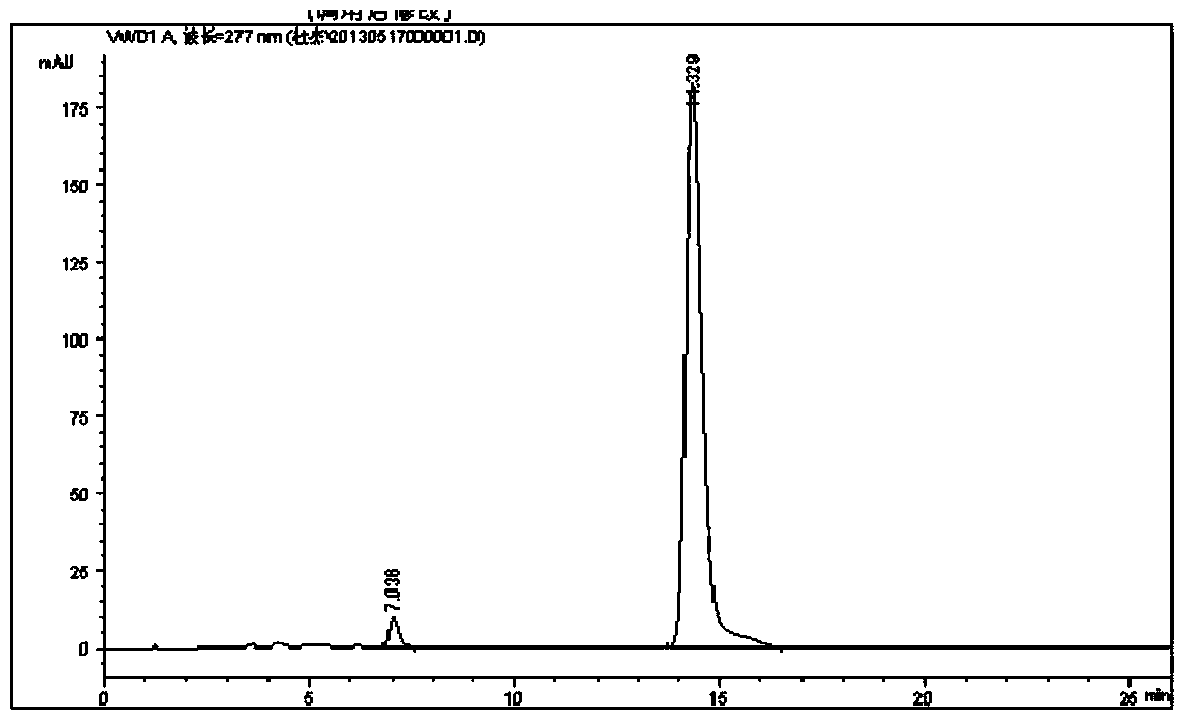

[0033] 3) Concentrate the filtrate to a paste. Part of the paste was dried and detected by HPLC as figure 1 shown. Add 8 times the volume of distilled water to the rest of the paste, filter under reduced pressure on filter paper, and obtain the filtrate;

[0034] 4) Concentrate the filtrate obtained in step 3) to 40% of the original volume, refrigerate at 4°C for 8 hours, filter under reduced pressure on filter paper, and obtain a precipitate;

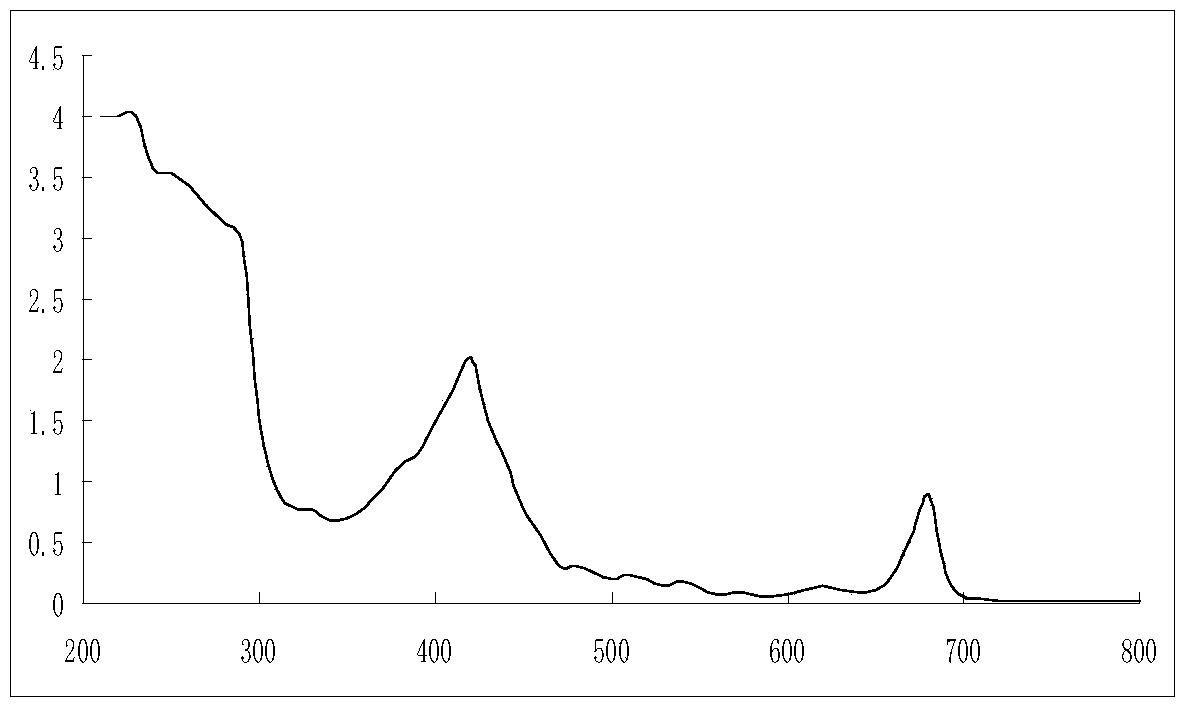

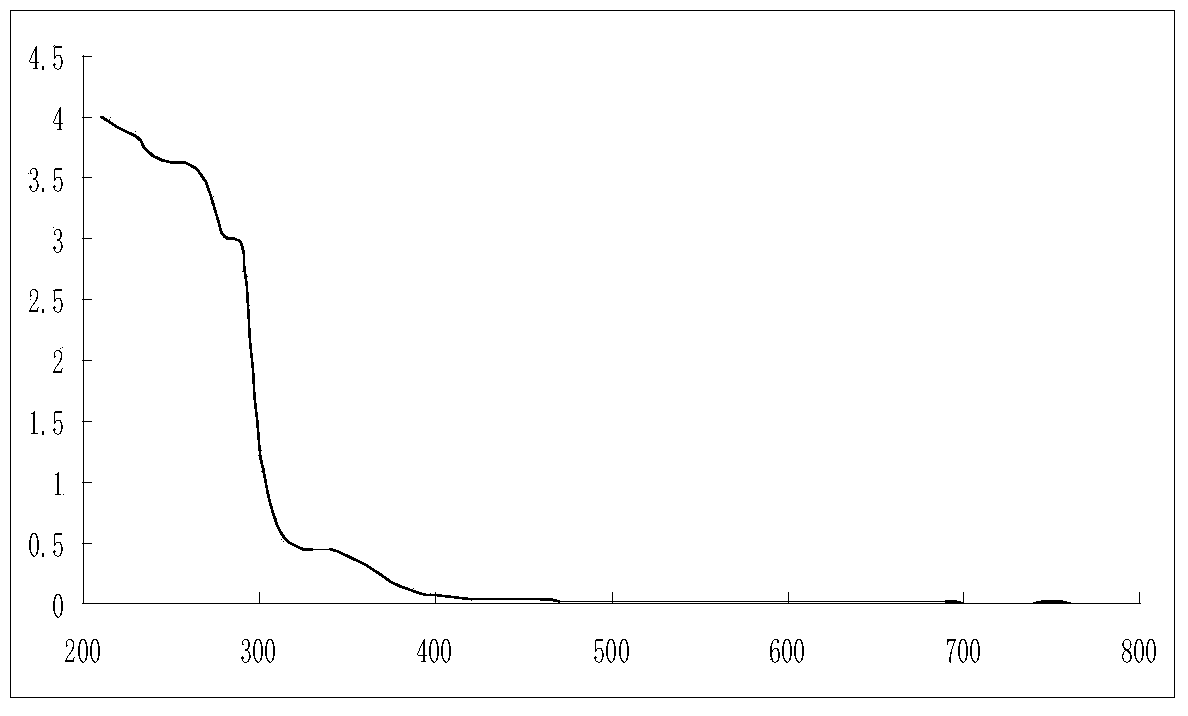

[0035] 5) Dissolve the precipitate with ethanol solution, add petroleum ether, the volume ratio of petroleum ether and ethanol is 1:1, mix well, stand for extraction for 8 hours, and obtain upper and lower layers of solution; figure 2 For the abso...

Embodiment 2

[0039] In step 2), absolute ethanol was back distilled and extracted 3 times, and the others were the same as in Example 1. 2.01 g of forsythin was obtained, and its purity was measured by HPLC, and the purity reached 98.4%.

Embodiment 3

[0041] In step 5), petroleum ether is added for extraction, the volume ratio of petroleum ether to ethanol is 0.5:1, and the others are the same as in Example 1. 1.97 g of forsythin was obtained, and its purity was measured by HPLC, and the purity reached 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com