Environmentally-friendly composite interior wall coating material and preparation method thereof

An interior wall coating and environmental protection technology, which is applied in the field of architectural interior wall coatings, can solve the problems of reducing drying time, harmful substances, coating environmental protection, pollution resistance, water resistance, scrub resistance defects, etc., and achieves the improvement of contrast ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

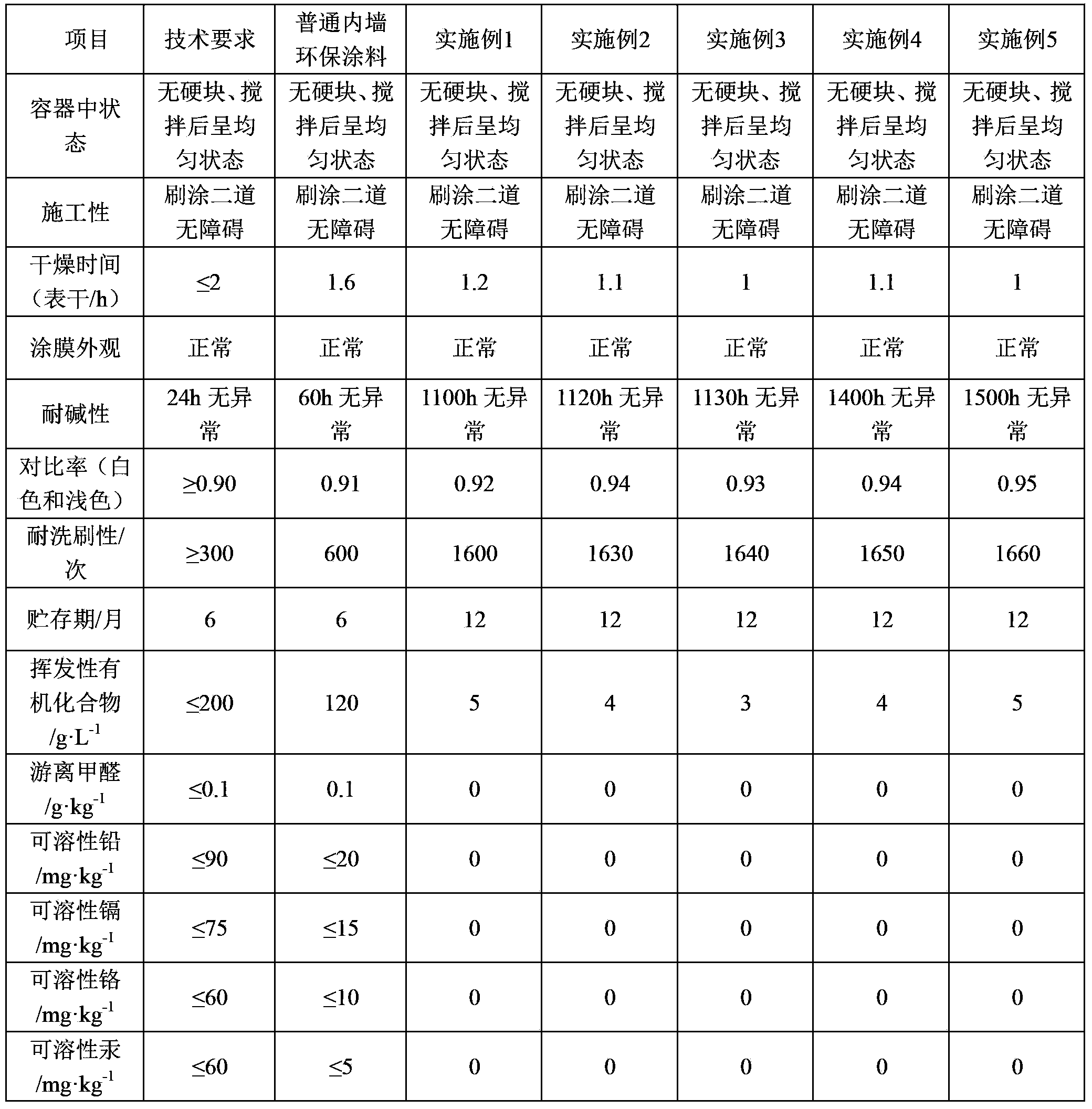

Examples

Embodiment 1

[0013] An environmentally friendly composite interior wall paint, the mass percentage of each component is: water 25%, polyvinyl acetate emulsion 17%, GHT-2DS pure acrylic emulsion 10%, 800 mesh sharp titanium dioxide 15%, 800 mesh Light calcium carbonate 18%, 800 mesh talcum powder 7.0%, 800 mesh bentonite 6.0%, lauryl alcohol ester 1.85%, ultramarine blue 0.12%, S-220 defoamer 0.02%, BEK-500 fungicide 0.01%.

[0014] The preparation method of the environment-friendly composite interior wall paint provided by the invention comprises the following steps:

[0015] (1) Add 800-mesh bentonite into the soaking bucket, add 1 / 3 of the mass of water and soak for 24 hours, set aside.

[0016] (2) Add the remaining 2 / 3 of the water, 800 mesh sharp titanium dioxide, 800 mesh light calcium carbonate, and 800 mesh talc powder into the ESJ500 mixer (speed range 50-2000rP / min, power 500w) in sequence, and control The rotation speed is 1200rpm, after stirring for 30 minutes, add all the ben...

Embodiment 2

[0020] An environmentally friendly composite interior wall paint, the mass percentage of each component is: water 20%, polyvinyl acetate emulsion 15%, GHT-2DS pure acrylic emulsion 15%, 800 mesh sharp titanium dioxide 19%, 800 mesh Light calcium carbonate 20%, 800 mesh talcum powder 5.0%, 800 mesh bentonite 4.7%, lauryl alcohol ester 1.0%, ultramarine blue 0.2%, S-220 defoamer 0.05%, BEK-500 fungicide 0.05%.

[0021] The preparation method of the environment-friendly composite interior wall paint provided by the invention comprises the following steps:

[0022] (1) Add 800-mesh bentonite into the soaking bucket, add 1 / 3 of the mass of water and soak for 24 hours, set aside.

[0023] (2) Add the remaining 2 / 3 of the water, 800 mesh sharp titanium dioxide, 800 mesh light calcium carbonate, and 800 mesh talc powder into the ESJ500 mixer (speed range 50-2000rP / min, power 500w) in sequence, and control Rotate at 1200rpm, stir for 29 minutes, then add all the bentonite soaked in st...

Embodiment 3

[0027] An environmentally friendly composite interior wall paint, the mass percentage of each component is: water 18%, polyvinyl acetate emulsion 20%, GHT-2DS pure acrylic emulsion 11%, 800 mesh sharp titanium dioxide 20%, 800 mesh Light calcium carbonate 15%, 800 mesh talc powder 8.0%, 800 mesh bentonite clay 7.0%, lauryl alcohol ester 0.72%, ultramarine blue 0.04%, S-220 defoamer 0.04%, BEK-500 fungicide 0.02%.

[0028] The preparation method of the environment-friendly composite interior wall paint provided by the invention comprises the following steps:

[0029] (1) Add 800-mesh bentonite into the soaking bucket, add 1 / 3 of the mass of water and soak for 24 hours, set aside.

[0030] (2) Add the remaining 2 / 3 of the water, 800 mesh sharp titanium dioxide, 800 mesh light calcium carbonate, and 800 mesh talc powder into the ESJ500 mixer (speed range 50-2000rP / min, power 500w) in sequence, and control Rotate at 1200rpm, stir for 31 minutes, then add all the bentonite soaked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com