Preparation method of high K hafnium dioxide amorphous film

A hafnium dioxide and amorphous thin film technology, which is applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem of incomplete formation of amorphous thin film, and achieve the suppression of multiphase mixing and optimization of structure Proportion, good compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

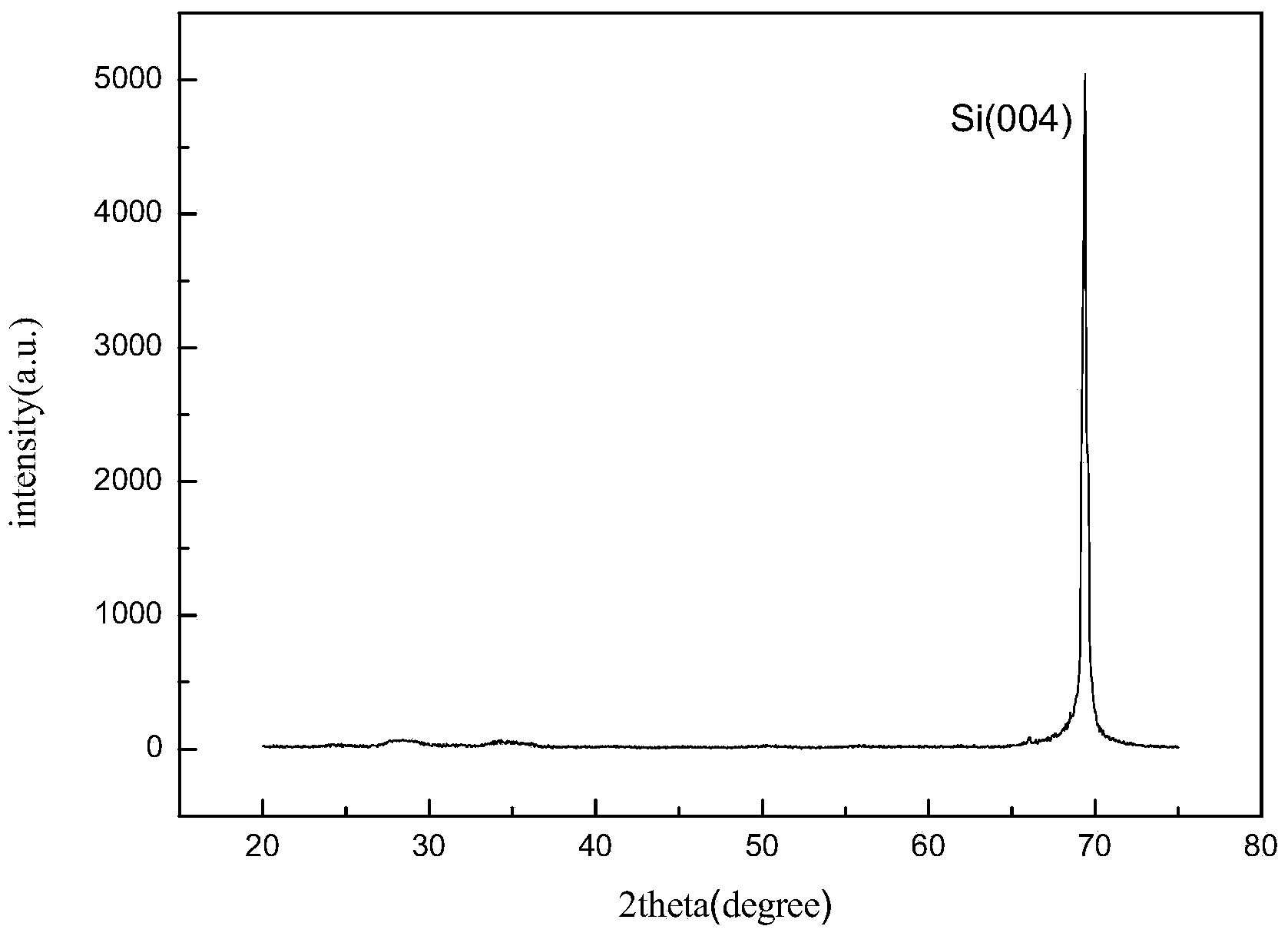

Image

Examples

Embodiment

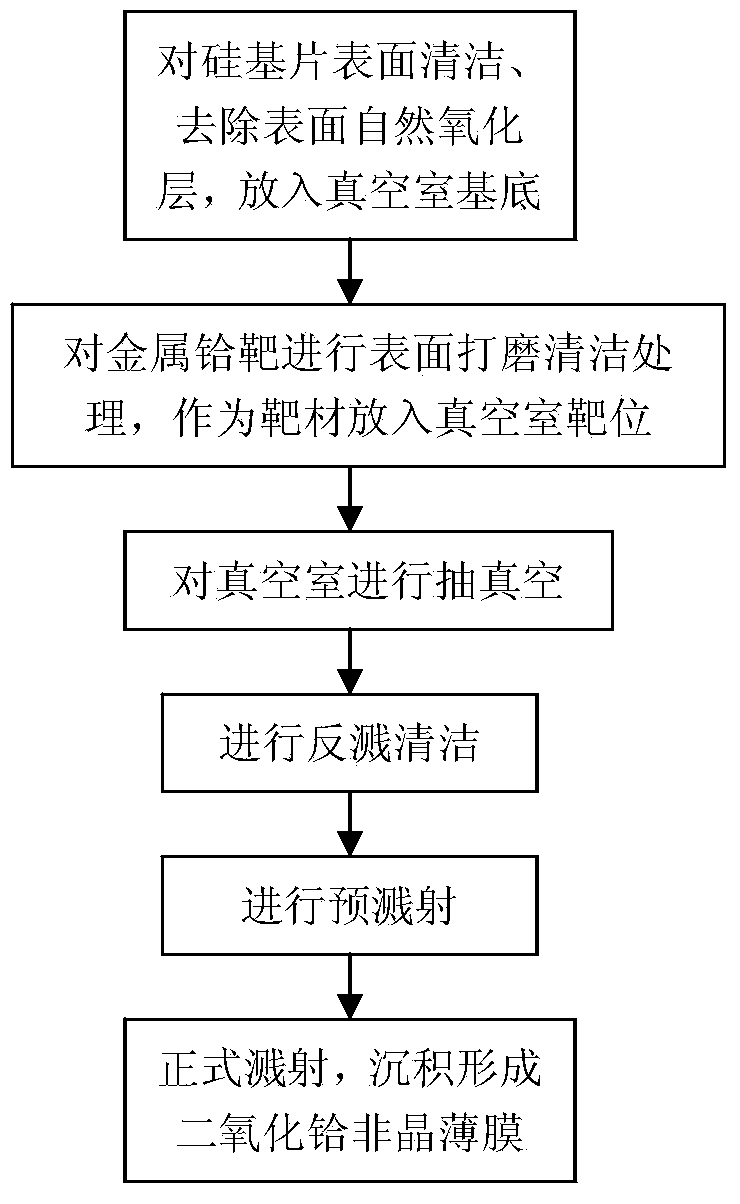

[0026] In this example, QX-500 high-vacuum multifunctional coating equipment is used. The preparation method of the high-K hafnium dioxide amorphous film in this example includes the following steps:

[0027] A. Clean the surface of the silicon substrate, remove the natural oxide layer on the surface of the silicon substrate, and put it into the base of the vacuum chamber.

[0028] In this step, the silicon substrate is a single-polish silicon substrate with n-type crystal orientation (100) of 10mm×10mm. This step is specifically: clean the silicon substrate with an ultrasonic cleaner in acetone and alcohol for a fixed period Carry out surface cleaning treatment, the fixed time is 10 to 15 minutes, after drying, soak in a certain concentration of hydrofluoric acid solution for a period of time to remove the natural oxide layer on the surface of the silicon substrate, the certain concentration can be about 5% , the period of time is 1 to 2 minutes, the silicon substrate is clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com