Main group V-VI metal compound laser crystal and preparation method thereof

A technology of metal compounds and laser crystals, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problem of narrow spectral bandwidth of lasers, and achieve the effect of wide application range and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Crucible descending method grows Bi 2 Te 3 the crystal

[0038] Using high-purity Bi and Te elemental substances as raw materials, the ratio of Bi and Te atomic numbers is 2:3 for ingredients, fully mixed evenly, heated and dehydrated;

[0039] Put the raw materials into a quartz crucible and vacuum seal it, put it into a crucible descending furnace using a silicon carbide rod as a heating element to grow crystals, set the material temperature to 620°C, and the crucible descending speed to 1mm / h;

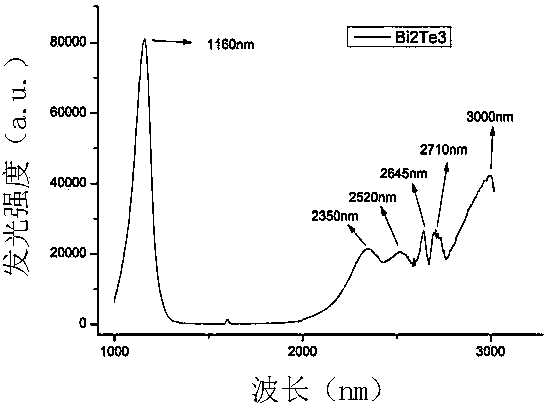

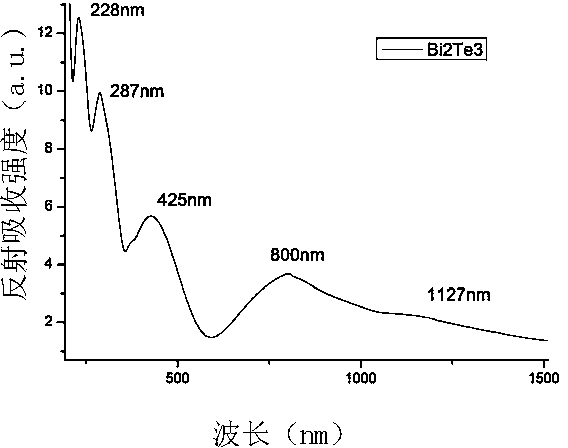

[0040] Cut the grown crystal into 10×10×3mm 3 After polishing, test the emission spectrum at room temperature on a ZOLIX SBP300 fluorescence spectrometer, using a laser diode or a solid-state laser with an emission wavelength in the range of 700-1000 nm as the pump source. Test results such as figure 1 As shown, there are two luminous bands in the emission spectrum, one of which is located near 1.16 μm in the near-infrared band, with a half-maximum width g...

Embodiment 2

[0042] Embodiment 2: grow under crucible drop method (Bi 11.3 Sb 29.6 ) Te 59.1 the crystal

[0043] Using high-purity Bi, Sb and Te simple substances as raw materials, according to the ratio of Bi, Sb and Te atomic number 11.3:29.6:59.1, mix well, heat and dehydrate;

[0044] Put the raw materials into the quartz crucible, first evacuate it, then fill it with argon gas, seal the crucible, put silicon carbide rods as heating elements in the crucible drop furnace to grow crystals, set the material temperature to 640°C, and crucible The descending speed is 2mm / h;

[0045] The grown Bi:CsI crystal is irradiated with γ-rays to further increase the concentration of near-infrared centers, the radiation dose is 10KGy, and the dose rate is 100Gy / h.

Embodiment 3

[0046] Embodiment 3: growing Bi by temperature gradient method x Te 3 the crystal

[0047] Using high-purity Bi and Te elemental substances as raw materials, the ratio of Bi and Te atomic numbers is 2:3, 1.8:3 and 2.2:3, respectively, for batching, fully mixed evenly, and heated for dehydration;

[0048] Put the raw materials into the graphite crucible, fill the crucible with high-purity argon, seal the crucible, put it into a temperature gradient furnace using high-purity graphite as the heating element to grow crystals, evacuate the furnace, and then fill it with high-purity argon Gas, set the chemical material temperature to 660°C, keep warm for 3 hours and then cool down to grow, and the temperature drop rate is 2°C / h;

[0049] Crystal irradiation can adopt the method shown in embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com