A kind of electrode material of supercapacitor

A technology for supercapacitors and electrode materials, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of poor voltage retention performance, large leakage current, and high impurity content, and achieve good conductivity, wide application range, and rich nitrogen content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] In the preparation method of the electrode material of the present invention, the polymerization reaction conditions generally include the temperature of contact and the time of contact, and the temperature of the contact only needs to ensure that the metal salt is in a molten state, so the contact The temperature can be from the melting point of the metal salt to lower than the boiling point of the metal salt, preferably, the temperature is 400-700° C.; the optional range of the contact time is wide, and in order to carry out the polymerization reaction more completely, the The contact time may be more than 20 hours, preferably, the contact time is 20-80 hours, more preferably, the contact time is 40-50 hours.

[0022] Since the temperature required to keep the metal salt in a molten state is generally high, the reaction in an open system may cause some unstable factors due to the difference in the environment. Preferably, the contact is carried out under an inert atmo...

Embodiment 1

[0033] This example is used to illustrate the preparation of the supercapacitor electrode material provided by the present invention.

[0034] Mix 1g (7.81mmol) of terephthalonitrile (p-DCB) and 5.32g (39.04mmol) of anhydrous zinc chloride, and transfer to a 10ml glass tube, replace the air in the glass tube with argon, After sealing it, put it in a muffle furnace, react at 550°C for 40 hours, cool it down to room temperature (25°C) naturally, open the glass tube, take out the polymerized product, and wash it with 5% by weight hydrochloric acid, purified water, tetrahydrofuran After washing, put it into an oven, and dry it at 120° C. for 10 hours to obtain an electrode material.

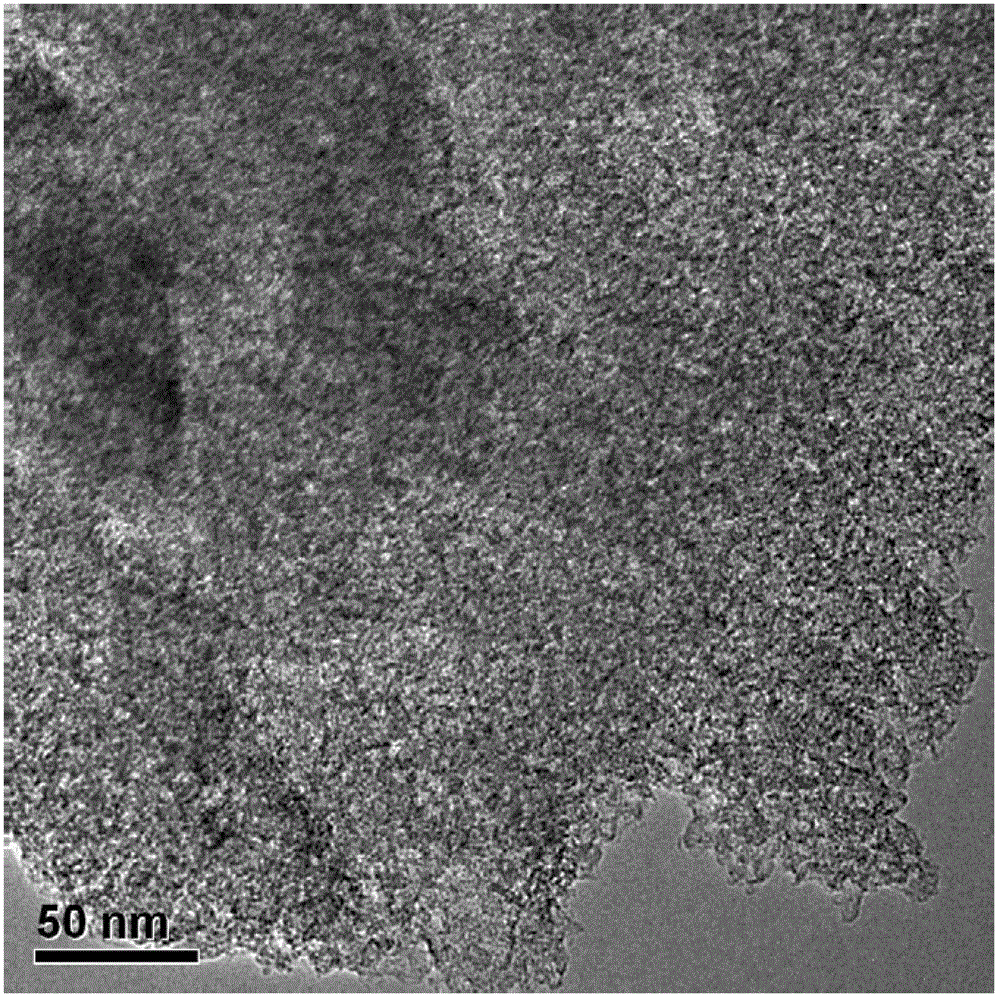

[0035] from figure 1 It can be seen that the electrode material prepared by this example has a loose and porous network structure.

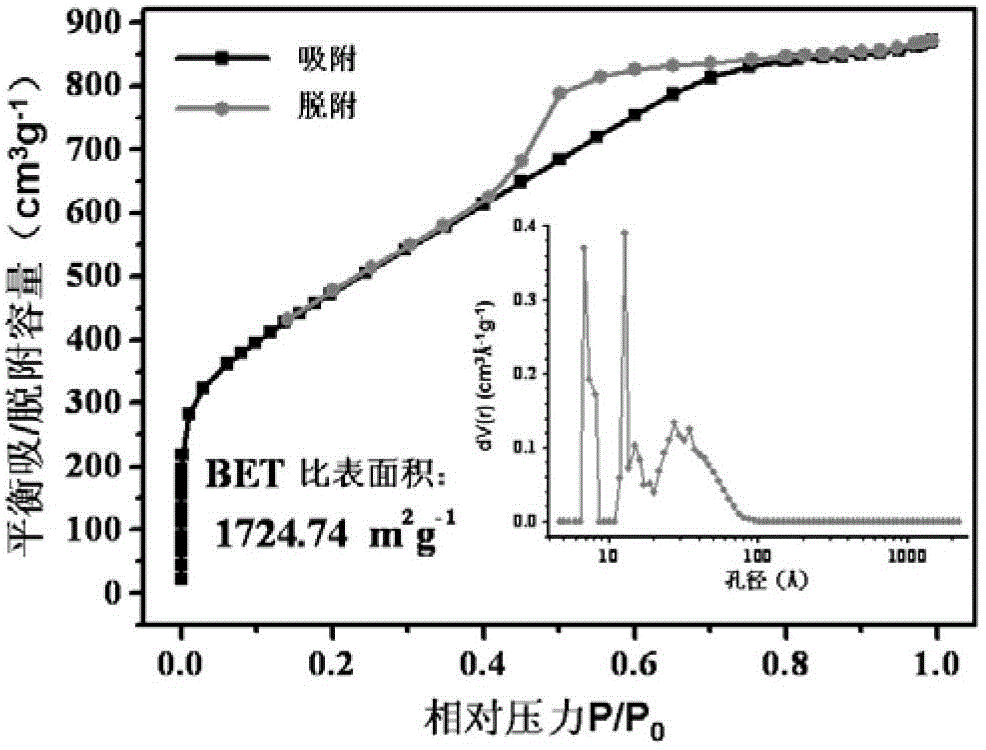

[0036] Depend on figure 2 According to the calculated data, the BET specific surface area of the prepared electrode material is 1724.74m 2 / g, the pore size dist...

Embodiment 2

[0038] This example is used to illustrate the preparation of the supercapacitor electrode material provided by the present invention.

[0039] The electrode material was prepared according to the method of Example 1, except that 1 g (7.81 mmol) of isophthalonitrile (m-DCB) was used as the raw material instead of 1 g (7.81 mmol) of terephthalonitrile (p-DCB). The BET specific surface area of the prepared electrode material is 1622m 2 / g, the pore size distribution of the electrode material is calculated by DFT method between 0.6-9nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com