Method for carrying out chemical oxidation repair on organic contaminated soil by compounding potassium permanganate (KMnO4) and hydrogen peroxide (H2O2)

A technology of organic pollution and potassium permanganate, applied in the field of soil remediation, can solve the problems of long repair time, difficult repair effect, high cost, etc., and achieve the effect of speeding up the repair speed, shortening the repair period, and improving the repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

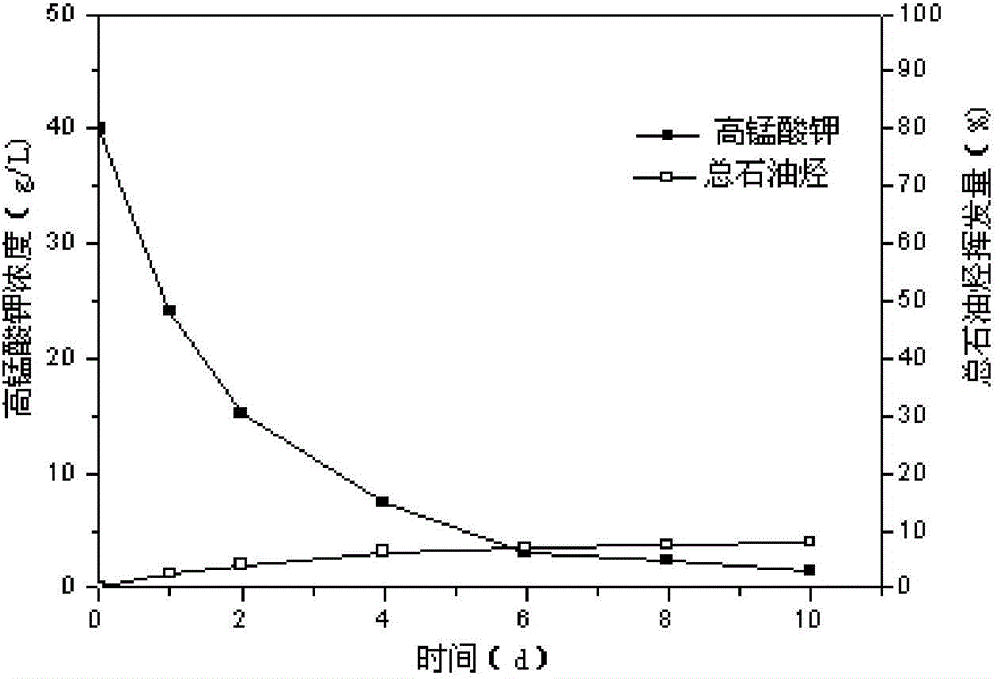

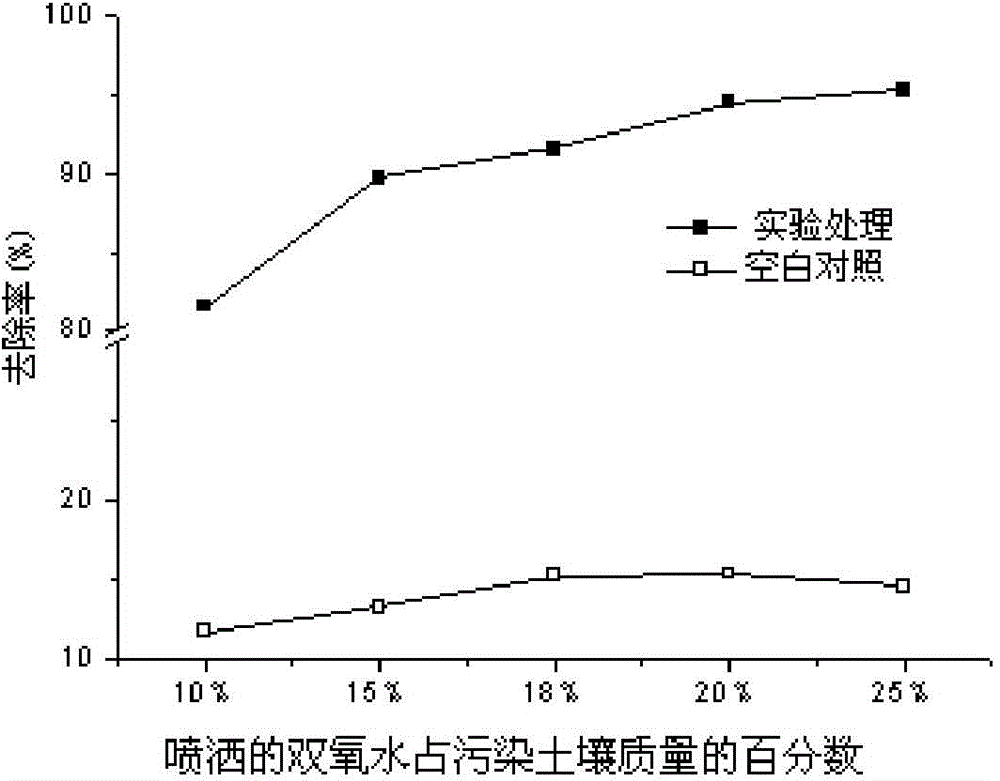

[0050] Embodiment 1 Establishment of the remediation method of petroleum-contaminated soil in a certain oil refinery

[0051] The soil of an oil refinery is polluted by petroleum, and its soil quality is sandy silt. Total petroleum hydrocarbons (TPH) is the characteristic pollutant of the site. The soil was dried to control the moisture content to be less than 15%, crushed, and the soil particles with a particle size of no more than 20mm were screened out, and the total petroleum hydrocarbon pollution concentration was measured to be 7142.85mg / kg.

[0052] 1. KMnO 4 Dosage Calculation

[0053] Method: Take organic polluted soil, dry it at low temperature to control the moisture content to be less than 15%, crush and sieve the soil particles with a particle size not greater than 20mm, weigh 20g of the soil under the sieve, put it in a brown VOC bottle, add 35ml40g to each bottle / L KMnO 4 Solution, cover the bottle cap, shake well, put it on a 360°rotary shaker, take the sup...

Embodiment 2

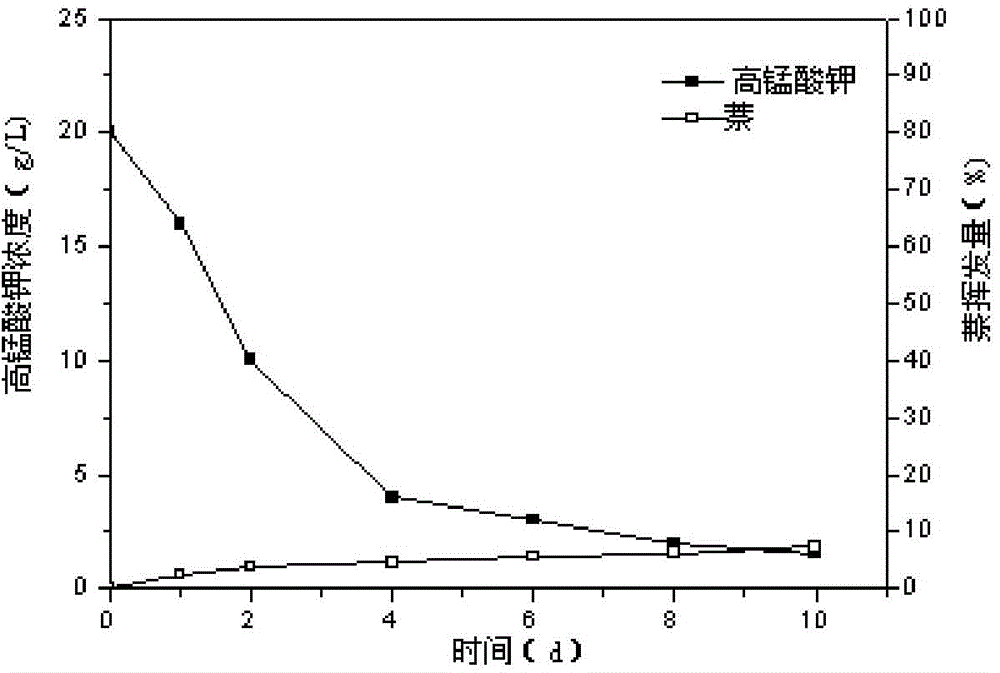

[0078] Example 2 Establishment of a remediation method for polycyclic aromatic hydrocarbons (PAHs) contaminated soil in a coking plant

[0079] The site of a coking plant was polluted by polycyclic aromatic hydrocarbons (PAHs), and the soil was sandy. Naphthalene was the characteristic pollutant of the site. The soil was dried to control the moisture content to be less than 15%, crushed, and the soil particles with a particle size of no more than 20 mm were screened out, and the naphthalene pollution concentration was measured to be 499.51 mg / kg.

[0080] 1. KMnO 4 Dosage Calculation

[0081] Method: Take organic polluted soil, dry it at low temperature to control the moisture content to be less than 15%, crush and sieve the soil particles with a particle size not greater than 20mm, take 20g of the polluted soil with a particle size not greater than 20mm under the sieve, and put it in a brown VOC bottle. Add 35ml20g / L of KMnO to each bottle 4 Solution, cover the bottle cap,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com