Method for production of phosphoric acid and coproduction of alkaline fertilizer from phosphate ore and potash feldspar

A technology of alkaline fertilizer and potassium feldspar, which is applied in the field of comprehensive utilization of resources and chemical production to achieve the effect of improving overall value, diverse nutrients and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

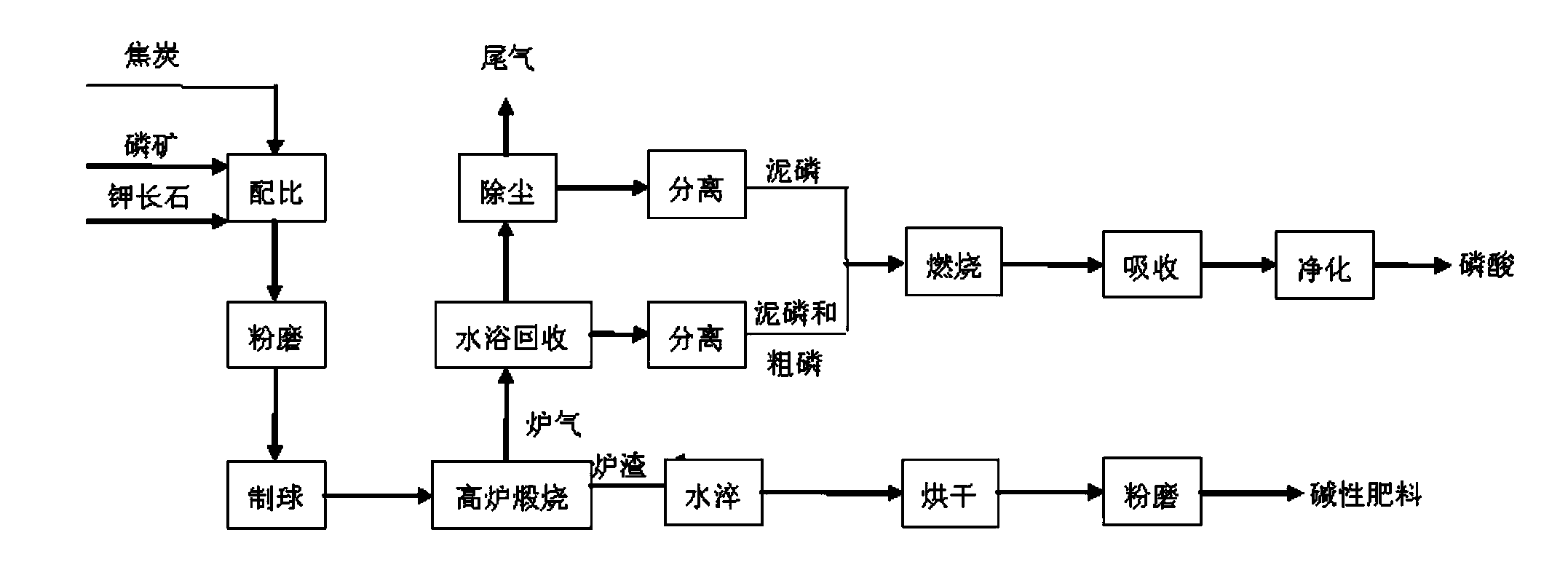

Method used

Image

Examples

Embodiment 1

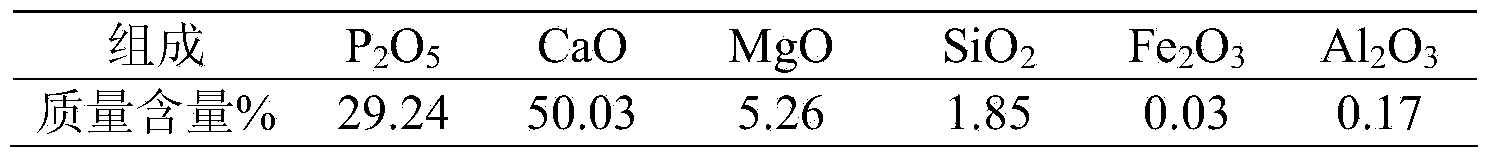

[0036] Raw material 1: Phosphate rock, collection location: Weng'an Mining Industry, Guizhou

[0037] The chemical composition of phosphate rock is shown in the table below:

[0038]

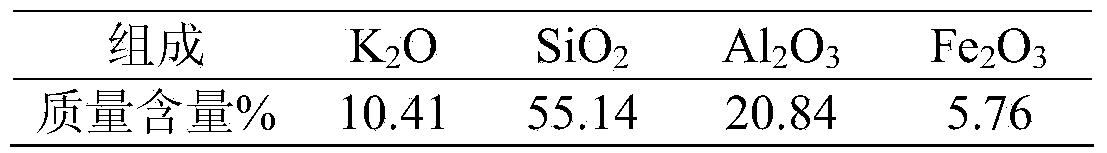

[0039] Raw material 2: Potassium feldspar, collection location: Qiping, Guizhou

[0040] The chemical composition of potassium feldspar is shown in the table below:

[0041]

[0042] A method for producing phosphoric acid co-production alkaline fertilizer with phosphate rock and potassium feldspar, comprising the steps:

[0043] Mix phosphate rock: potassium feldspar: coke according to the mass ratio of 1:1:0.32. After grinding, pass through a 100-mesh sieve, add water to make balls, and calcinate in a blast furnace at 1350°C for 30 minutes to obtain slag and blast furnace gas;

[0044] The blast furnace gas is cooled by a normal temperature water bath in the phosphorus receiving tank to obtain crude phosphorus and most of the phosphorus sludge. The blast furnace gas that has been prelim...

Embodiment 2

[0049] Raw material 1: Phosphate rock, collection location: Jinde Mining, Guizhou

[0050] The chemical composition of phosphate rock is shown in the table below:

[0051]

[0052] Raw material 2: Potassium feldspar, collection location: Jinde Mining, Guizhou

[0053] The chemical composition of potassium feldspar is shown in the table below:

[0054]

[0055] A method for producing phosphoric acid co-production alkaline fertilizer with phosphate rock and potassium feldspar, comprising the steps:

[0056] Mix phosphate rock: potassium feldspar: coke according to the mass ratio of 1:0.65:0.26. After grinding, pass through a 120-mesh sieve, add water to make balls, and calcinate in a blast furnace at 1150°C for 120 minutes to obtain slag and blast furnace gas;

[0057] The blast furnace gas is rinsed and cooled by a three-stage absorption tower in series at room temperature to obtain crude phosphorus and most of the phosphorus sludge. The blast furnace gas that has been ...

Embodiment 3

[0062] Raw material 1: Phosphate rock, collection location: Weng'an Mining Industry, Guizhou

[0063] The chemical composition of phosphate rock is shown in the table below:

[0064]

[0065] Raw material 2: Potassium feldspar, collection location: Jinde Mining, Guizhou

[0066] The chemical composition of potassium feldspar is shown in the table below:

[0067]

[0068] A method for producing phosphoric acid co-production alkaline fertilizer with phosphate rock and potassium feldspar, comprising the steps:

[0069] Mix phosphate rock: potassium feldspar: coke according to the mass ratio of 1:0.92:0.30, after grinding, pass through a 150-mesh sieve, add water to make balls, and calcinate in a blast furnace at 1200°C for 90 minutes to obtain slag and blast furnace gas;

[0070] The blast furnace gas is cooled by a normal temperature water bath in the phosphorus receiving tank to obtain crude phosphorus and most of the phosphorus sludge. The blast furnace gas that has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com