Preparation method of strontium ranelate

A technology of strontium ranelate and strontium salt, which is applied in the field of preparation of strontium ranelate and its hydrate, can solve the problems of easy decarboxylation, difficult quality control, difficult to meet the purity requirements, and achieve high content and controllable product quality , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

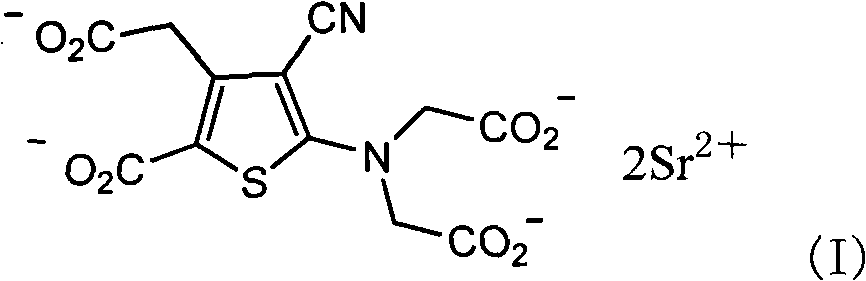

[0025] Add 0.6KG tetraethyl ranelate, 5L ethanol, and potassium hydroxide aqueous solution (0.31KG potassium hydroxide dissolved in 3L water) to a 10L reactor, heat to reflux, and react for 4 hours. The solvent was removed from the reaction solution to obtain 0.91KG of a light yellow viscous substance. Add 3.6L of water / methanol (volume ratio 1:7) mixed solution, heat to dissolve to obtain a brownish-yellow solution, cool down and wash, filter to obtain 0.44KG sodium ranelate refined product, yield 67.4%.

[0026] Dissolve potassium ranelate 0.44KG in 1.8L water, heat to reflux, add aqueous strontium chloride solution (0.37Kg dissolved in 2.5KG water) and continue to reflux for 2 hours, heat filter, dry to obtain strontium ranelate hydrate 0.51KG, and collect The rate is 87.2%. Content 98.6%, maximum impurity 0.05%.

Embodiment 2

[0028] Add 0.6KG tetraethyl ranelate, 5L ethanol, and aqueous sodium hydroxide solution (0.22KG sodium hydroxide dissolved in 3L water) to a 10L reactor, heat to reflux, and react for 4 hours. The solvent was removed from the reaction liquid to obtain 0.80KG of a light yellow viscous substance. Add 4.8 L of water / methanol (volume ratio 1:5) mixed solution, heat to dissolve to obtain a brownish-yellow solution, cool down and wash, filter to obtain 0.43KG sodium ranelate refined product, yield 75.7%.

[0029] Dissolve sodium ranelate 0.43KG in 1.8L water, heat to reflux, add strontium chloride aqueous solution (0.59Kg dissolved in 2.5KG water) and continue to reflux for 2 hours, heat filter, dry to obtain strontium ranelate hydrate 0.57KG, and collect The rate is 86.7%. Content 98.8%, maximum impurity 0.04%.

Embodiment 3

[0031] Add 0.6KG tetraethyl ranelate, 5L ethanol, and sodium hydroxide aqueous solution (0.22KG sodium hydroxide dissolved in 3L distilled water) into a 10L reactor, heat to reflux, and react for 4 hours. The solvent was removed from the reaction liquid to obtain 0.80KG of a light yellow viscous substance. Add 4.8 L of distilled water / methanol (volume ratio 1:5) mixed solution, heat to dissolve to obtain a brownish-yellow solution, cool down and wash, filter to obtain 0.44KG sodium ranelate fine product, yield 77.5%.

[0032] Dissolve sodium ranelate 0.44KG in 1.8L distilled water, heat to reflux, add strontium chloride aqueous solution (0.60Kg dissolved in 2.5KG distilled water) and continue to reflux for 2 hours, heat filter, and dry to obtain strontium ranelate hydrate 0.58KG , yield 86.2%. Content 99.7%, maximum impurity 0.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com