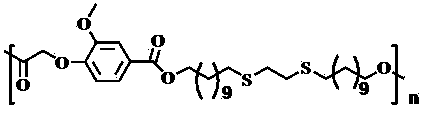

Preparation method for degradable polyester from 10-undecenoic acid and vanillic acid

A technology for degrading polyester and dimethyl vanillate, which is applied in the fields of renewable resource utilization and green synthesis, can solve the problems of hindering the application of renewable resources, complicated separation process, long reaction time, etc., and achieves easy structure and function, raw material Wide range of sources, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] A method for preparing degradable polyester based on 10-undecylenic acid and vanillic acid, using vegetable oil-based unsaturated fatty acid and vanillic acid as raw materials, using n-butyl titanate as a catalyst, and realizing it under high temperature and high vacuum conditions Ontology aggregation, the steps are as follows:

[0028] 1) Preparation of 10-undecen-1-ol from 10-undecenoic acid

[0029] Dissolve 1.84 g (10.0 mmol) of 10-undecenoic acid in 20.0 mL of anhydrous tetrahydrofuran in the reaction flask, place the reaction flask in an ice-water bath, slowly add 0.94 g of lithium tetrahydrogen aluminum within 30 min, remove In an ice-water bath, react at room temperature for another 3 h, then reflux for 1 h. After the reaction was completed, 50 mL of distilled water and 100 mL of 2 M hydrochloric acid were successively added to the reaction system, extracted three times with 50 mL of ethyl acetate, the organic phase was washed with saturated NaCl solution and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com