Gold and silver alloy bonding wire with gold-plated layer on surface and preparation method thereof

A technology of gold-silver alloy and gold-plated layer, applied in the field of gold-silver alloy bonding wire and its preparation, can solve problems such as incompatibility, and achieve the effects of smooth surface, low price, and reduced packaging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

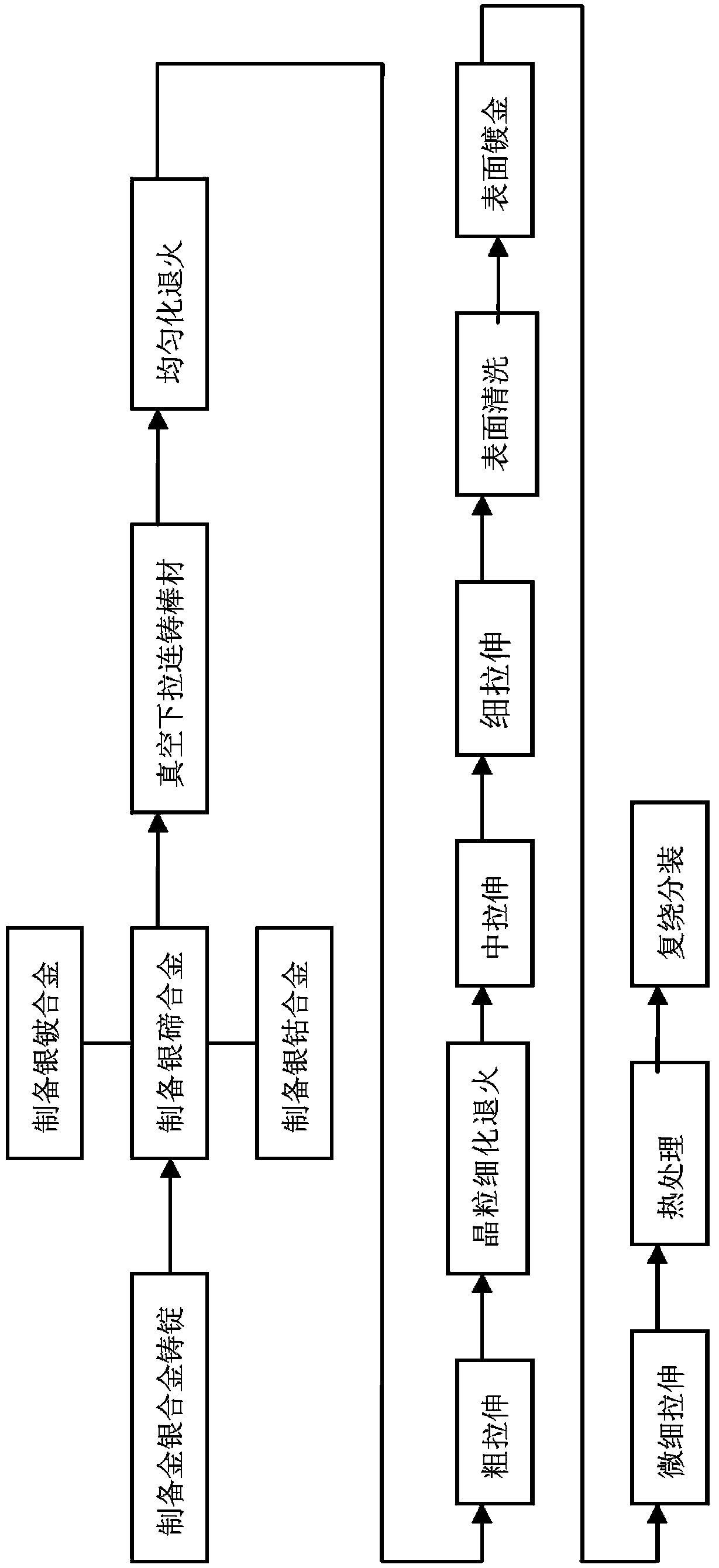

Method used

Image

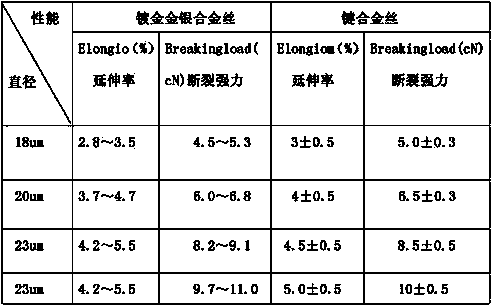

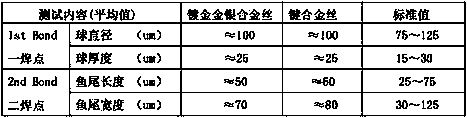

Examples

Embodiment 1

[0070] 1) Select silver ingots with a purity of ≥99.99% and gold ingots with a purity of ≥99.99%, first wash them with 10% sodium hydroxide, then rinse them with deionized water, and dry them in an oven for later use.

[0071] 2) Preparation of gold and silver alloy ingots: put silver ingots with a purity of ≥99.99% and gold ingots with a purity of ≥99.99% in proportion to a high-purity graphite crucible, place them in a vacuum melting furnace, and conduct intermediate frequency induction heating to 1100 ℃, during the heating process, vacuum treatment; after the material is completely melted, fill it with high-purity nitrogen and keep it warm for 30 minutes; pour the liquid gold-silver alloy into a high-purity graphite tank to obtain gold and silver with a width of 5 cm, a thickness of 1 cm, and a gold content of 7%. Alloy ingots.

[0072] 3) Preparation of silver-beryllium alloy rods: put 99.99% pure silver and trace element beryllium in a high-purity graphite crucible,...

Embodiment 2

[0087] 1) Select silver ingots with a purity of ≥99.99% and gold ingots with a purity of ≥99.99%, first wash them with 17.5% sodium hydroxide, then rinse them with deionized water, and dry them in an oven for later use.

[0088] 2) Preparation of gold and silver alloy ingots: put silver ingots with a purity of ≥99.99% and gold ingots with a purity of ≥99.99% in proportion to a high-purity graphite crucible, place them in a vacuum melting furnace, and conduct intermediate frequency induction heating to 1200 ℃, during the heating process, vacuum treatment; after the material is completely melted, fill it with high-purity nitrogen and keep it warm for 60 minutes; pour the liquid gold-silver alloy into a high-purity graphite tank to obtain a gold with a width of 7.5cm, a thickness of 1cm, and a gold content of 7%. Silver alloy ingots.

[0089] 3) Preparation of silver-beryllium alloy rods: put 99.99% pure silver and trace element beryllium in a high-purity graphite crucible,...

Embodiment 3

[0104] 1) Select silver ingots with a purity of ≥99.99% and gold ingots with a purity of ≥99.99%, first wash them with 17.5% sodium hydroxide, then rinse them with deionized water, and dry them in an oven for later use.

[0105] 2) Preparation of gold and silver alloy ingots: put silver ingots with a purity of ≥99.99% and gold ingots with a purity of ≥99.99% in proportion to a high-purity graphite crucible, place them in a vacuum melting furnace, and conduct intermediate frequency induction heating to 1200 ℃, during the heating process, vacuum treatment; after the material is completely melted, fill it with high-purity nitrogen and keep it warm for 60 minutes; pour the liquid gold-silver alloy into a high-purity graphite tank to obtain a gold with a width of 7.5cm, a thickness of 1cm, and a gold content of 10%. Silver alloy alloy ingot.

[0106] 3) Preparation of silver-beryllium alloy rods: put 99.99% pure silver and trace element beryllium in a high-purity graphite cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com