Organic solar cell and manufacturing method thereof

A technology of a solar cell and a manufacturing method, applied in the field of solar cells, can solve the problems of limited improvement of photoelectric conversion efficiency, inability to fully absorb scattered light, uncontrollable randomness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

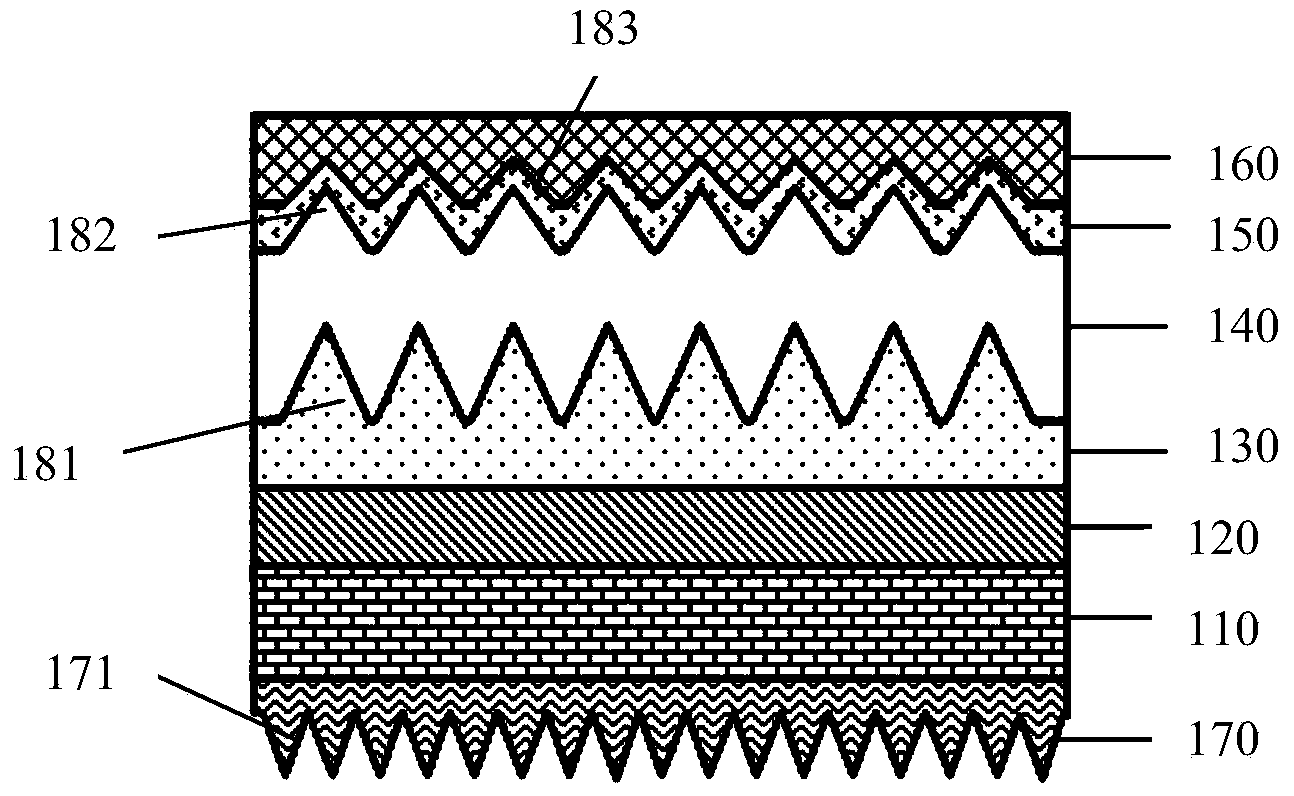

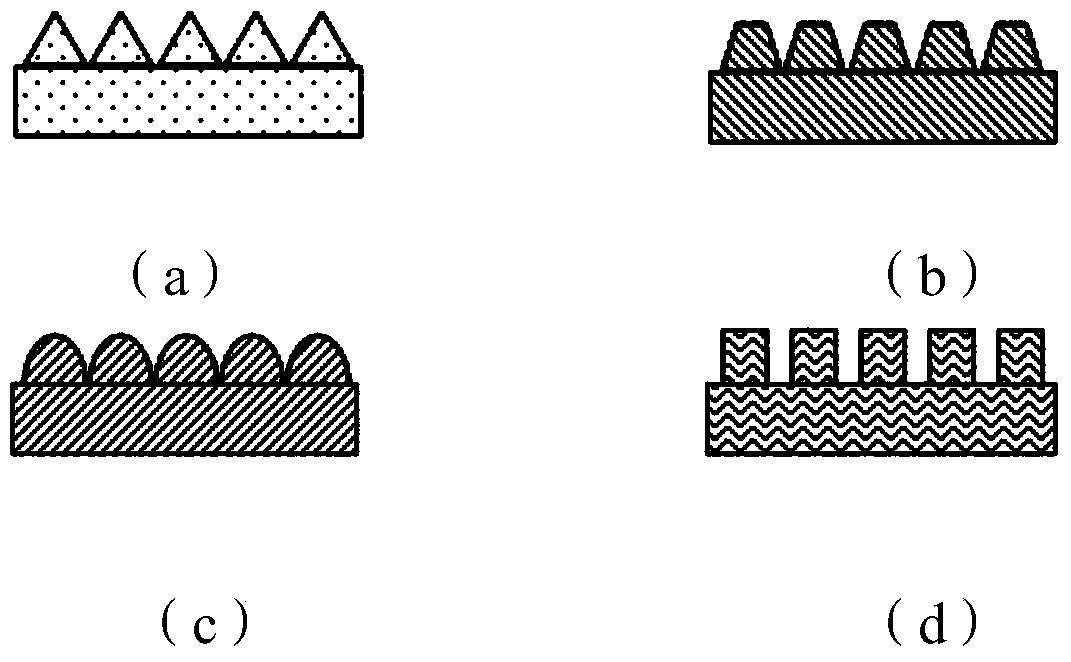

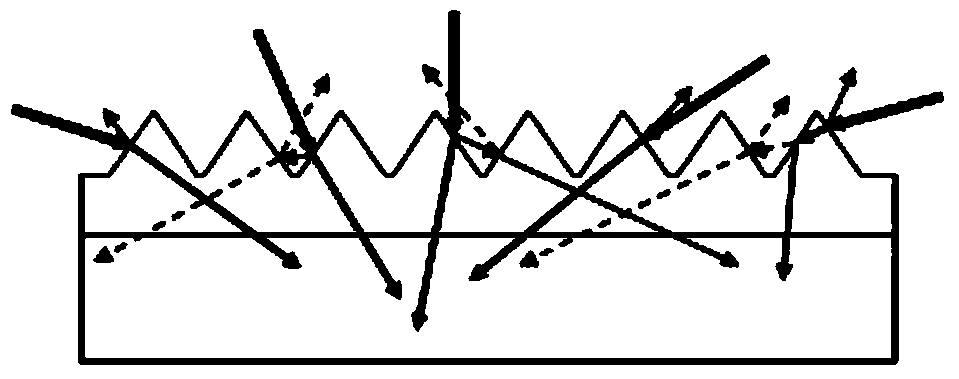

[0067] The embodiment of the present invention discloses an organic solar cell, comprising a substrate, and a first electrode, a first charge transport layer, a photoactive layer, a second charge transport layer and a second electrode sequentially located on one surface of the substrate, wherein, The other surface of the substrate is provided with an anti-reflection layer, and the anti-reflection layer has a first nano-concave-convex structure whose refractive index changes gradually along the direction of incident light.

[0068] The embodiment of the present invention discloses a method for manufacturing an organic solar cell as described above, wherein the operation steps include:

[0069] a10), coating a colloidal or semi-colloidal material layer on the surface of the substrate;

[0070] b10), performing a nano soft imprint process on the material layer to obtain an anti-reflection layer, and the anti-reflection layer has a first nano-concave-convex structure whose refract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com