Method for synchronously separating lotus leaf flavone and chlorophyll from fresh lotus leaves

A technology for synchronous separation of lotus leaf flavonoids, applied in chemical instruments and methods, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the waste of lotus leaf chlorophyll, low content of lotus leaf flavonoids, high content of impurities in lotus leaf flavonoids, etc. problems, to achieve the effect of improving purity and yield, increasing added value, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

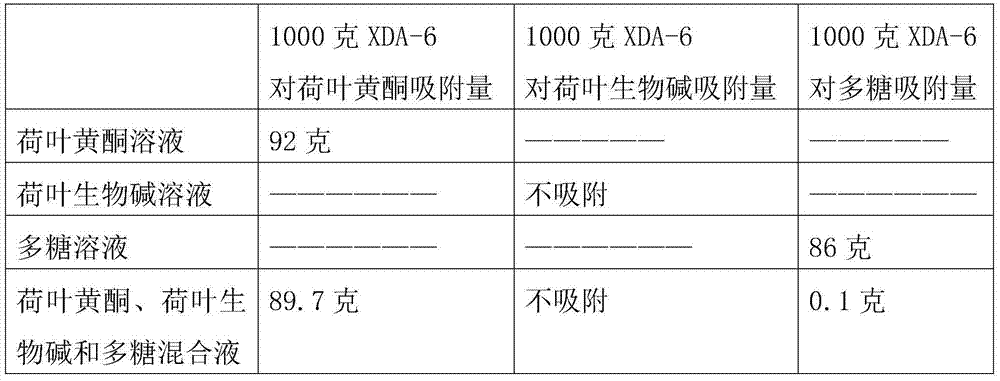

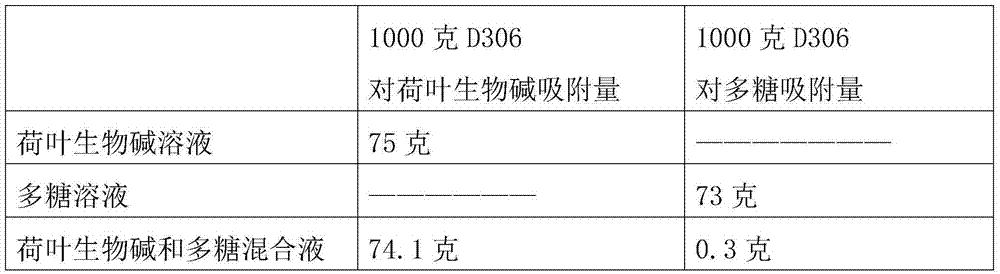

Embodiment 1

[0025] Crush the fresh lotus leaves, add 1 part by weight of fresh lotus leaves and 15 parts by weight of ethanol with a mass concentration of 90% in the extraction tank, extract 3 times at 50°C for 1.5 hours each time, combine the extracts, and add to the extracts Petroleum ether is added to the mixture, and the volume ratio of the extract to the added petroleum ether is 3:1, stirred, and left to stand to obtain an extract layer containing petroleum ether and chlorophyll and a layer containing ethanol, lotus leaf flavonoids, lotus leaf alkaloids and polysaccharides. Raffinate layer.

[0026] The extract containing petroleum ether and chlorophyll is concentrated under reduced pressure at a vacuum degree of 700mmHg to obtain a green oily liquid, and the green oily liquid is subjected to microwave vacuum drying at a vacuum degree of 740mmhg and a temperature of 60°C to obtain a chlorophyll powder. , the color value of the obtained chlorophyll reaches 240, and the yield can reach...

Embodiment 2

[0030] Crush the fresh lotus leaves, add 1 part by weight of fresh lotus leaves and 8 parts by weight of ethanol with a mass concentration of 95% in the extraction tank, extract 4 times at 80°C for 2 hours each time, combine the extracts, and add to the extracts Add sherwood oil, the volume ratio of the extract and the added sherwood oil is 2:1, stir, leave standstill, obtain the extract liquid layer that contains petroleum ether and chlorophyll and contain ethanol, lotus leaf flavonoids, lotus leaf alkaloids and polysaccharide Raffinate layer.

[0031] The extract containing petroleum ether and chlorophyll is concentrated under reduced pressure at a vacuum degree of 750mmHg to obtain a green oily liquid, and the green oily liquid is subjected to microwave vacuum drying at a vacuum degree of 760mmhg and a temperature of 55°C to obtain a chlorophyll powder. , the color value of the obtained chlorophyll reaches 260, and the yield can reach 92% (yield=quality of chlorophyll obtai...

Embodiment 3

[0036] Crush the fresh lotus leaves, add 1 part by weight of fresh lotus leaves and 25 parts by weight of ethanol with a mass concentration of 90% in the extraction tank, extract twice at 80°C for 1 hour each time, combine the extracts, and add to the extraction tank Add petroleum ether to the liquid, the volume ratio of the extract to the added petroleum ether is 3:1, stir, and let it stand to obtain an extract layer containing petroleum ether and chlorophyll and containing ethanol, lotus leaf flavonoids, lotus leaf alkaloids and polysaccharides raffinate layer.

[0037] Concentrate the extract containing petroleum ether and chlorophyll under reduced pressure at a vacuum degree of 800mmHg to obtain a green oily liquid, and dry the green oily liquid in a microwave vacuum at a vacuum degree of 800mmhg and a temperature of 50°C to obtain a chlorophyll powder. , the color value of the obtained chlorophyll reaches 210, and the yield can reach 90.7% (yield=quality of chlorophyll ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com