Preparation method of polyepichlorohydrin-ethanediamine decolorizing agent

A polyepichlorohydrin and epichlorohydrin technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem of high treatment cost, and achieve the effect of improving the conversion rate, wide application range and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

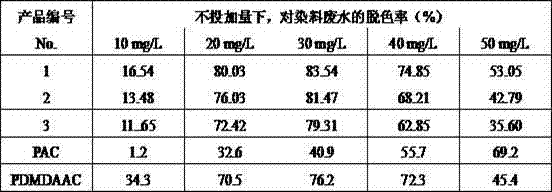

Examples

Embodiment 1

[0017] Take 24mL of liquid paraffin in a 250mL four-necked round-bottomed flask equipped with a stirrer, thermometer and reflux condenser, place the flask in an ice-water bath, control the temperature at 8°C, and feed a flow rate of 0.5m into the flask. 3 Nitrogen for 15 minutes per hour, then weigh 6.02 g of ethylenediamine and add it to the round bottom flask (the mass ratio of ethylenediamine to liquid paraffin is 1:3), open the cooling water of the reflux condenser, and stir at a G value of 150 S -1 While stirring, the temperature was raised to 25 °C, and 18.56 g of epichlorohydrin (the molar ratio of epichlorohydrin to ethylenediamine was 2:1) was slowly added dropwise with a separatory funnel for addition reaction, and the dropping time was 2.5 hours. After the dropwise addition, continue to stir for 60 minutes; then lower the temperature to below 15°C, and add a trimethylamine crosslinking agent with a mass percentage concentration of 33% according to the molar ratio of ...

Embodiment 2

[0020] Take 48mL of liquid paraffin in a 250mL four-neck round bottom flask, place the flask in an ice-water bath, control the temperature at 5°C, and feed a flow rate of 0.5m into the flask. 3 Nitrogen per hour for 20 minutes, then weigh 12.05 g of ethylenediamine and add it to the round bottom bottle, open the cooling water of the reflux condenser, and stir at a G value of 200 S -1 While stirring, the temperature was raised to 20 ° C, and 18.57 g of epichlorohydrin (the molar ratio of epichlorohydrin to ethylenediamine was 1:1) was slowly added dropwise with a separatory funnel for addition reaction, and the dropping time was 2 hours. Continue to stir for 70 minutes after the dropwise addition; then lower the temperature to 15°C, add 33% trimethylamine crosslinking agent according to the molar ratio of trimethylamine and epichlorohydrin 1:1.5; raise the temperature to 90°C again, and keep the constant temperature React for 5 hours, filter the obtained product to obtain a sol...

Embodiment 3

[0023] Take 96mL of liquid paraffin in a 250mL four-necked round bottom flask, place the flask in an ice-water bath, control the temperature at 0°C, and feed a flow rate of 0.5m into the flask. 3 Nitrogen per hour for 18 minutes, then weigh 24.1 g of ethylenediamine and add it to the round bottom bottle, open the cooling water of the reflux condenser, and stir at G value of 250 S -1 While stirring, the temperature was raised to 23 ° C, and 18.57 g of epichlorohydrin (the molar ratio of epichlorohydrin to ethylenediamine was 1:2) was slowly added dropwise with a separatory funnel for addition reaction, and the dropping time was 3 hours. Continue to stir for 90 minutes after the dropwise addition; then lower the temperature to 15°C, add 33% trimethylamine crosslinking agent according to the molar ratio of trimethylamine and epichlorohydrin 1:1.5; raise the temperature to 87°C again, React for 5 hours, filter the obtained product to obtain a solid product, wash with toluene 2-3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com