Preparation method of composite structure of photoresist film and substrate for LIGA (Lithographie, Galvanoformung and Abformung) technology

A composite structure, photoresist technology, applied in microlithography exposure equipment, processes for producing decorative surface effects, microstructure technology, etc., can solve the problem of limited bonding area, peeling, and collapse of PMMA photoresist column structure and other issues to achieve the effect of improving research level and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

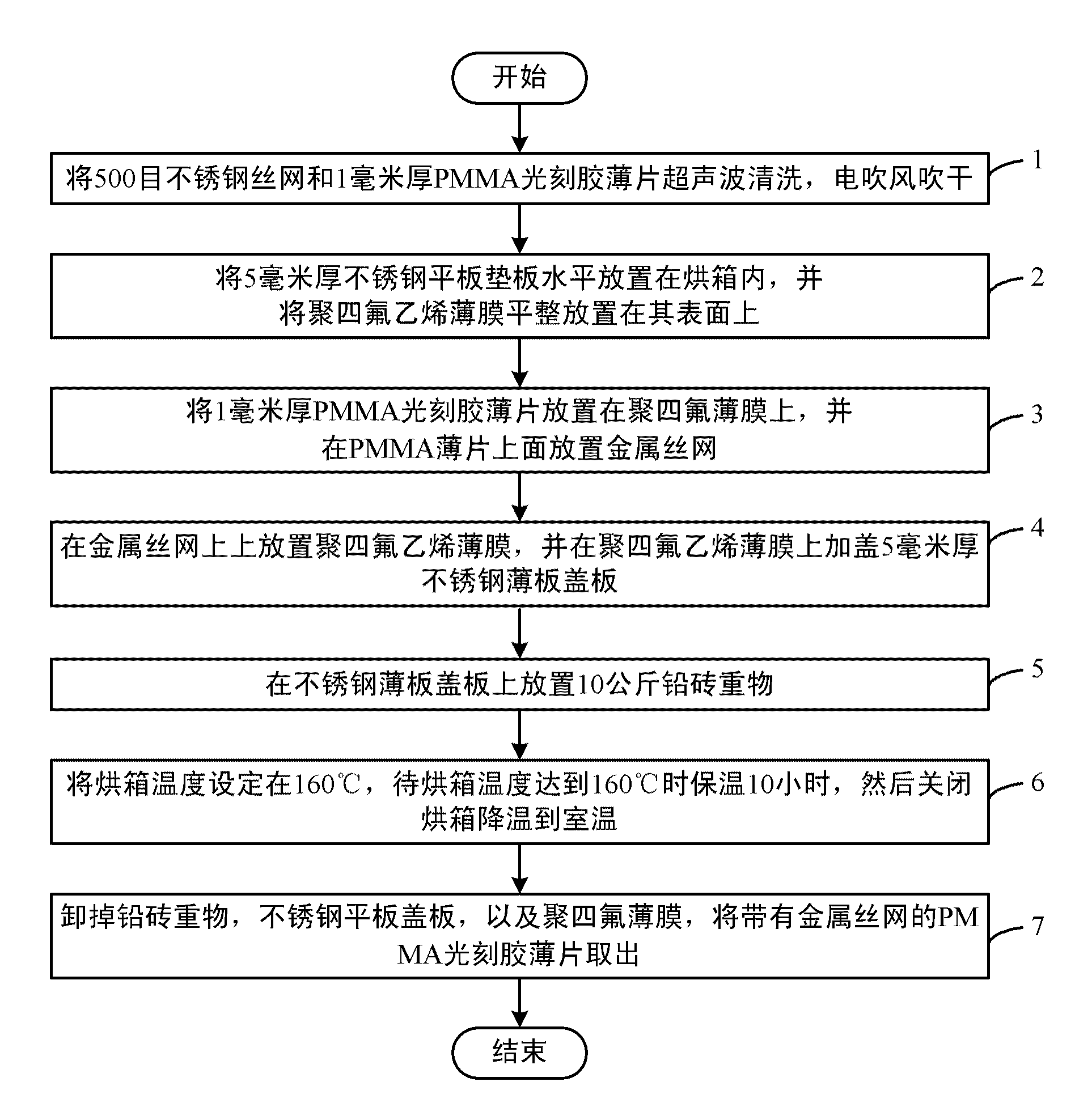

[0026] Such as figure 1 as shown, figure 1 It is a flow chart of a method for preparing a composite structure of a photoresist film and a substrate for LIGA technology according to an embodiment of the present invention, and the method includes:

[0027] Step 1: Clean the 500-mesh stainless steel wire mesh and the 1 mm thick PMMA photoresist sheet ultrasonically, and dry them with a hair dryer.

[0028] Step 2: Place the 5 mm thick stainless steel flat plate horizontally in the oven, and place the PTFE film flat on its surface.

[0029] Step 3: Place a 1 mm thick PMMA photoresist sheet on the PTFE film, and place a wire mesh on top of the PMMA sheet.

[0030] Step 4: Place a polytetrafluoroethylene film on the wire mesh, and cover the polytetrafluoroethylene film with a 5 mm thick stainless steel sheet cover; the polytetrafluoroethylene film prevents the PMMA photoresist from melting through the stainless steel mesh and The adhesion of the stainless steel flat backing plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com