A lithium-rich manganese-based mixed conductor positive electrode material and preparation method thereof

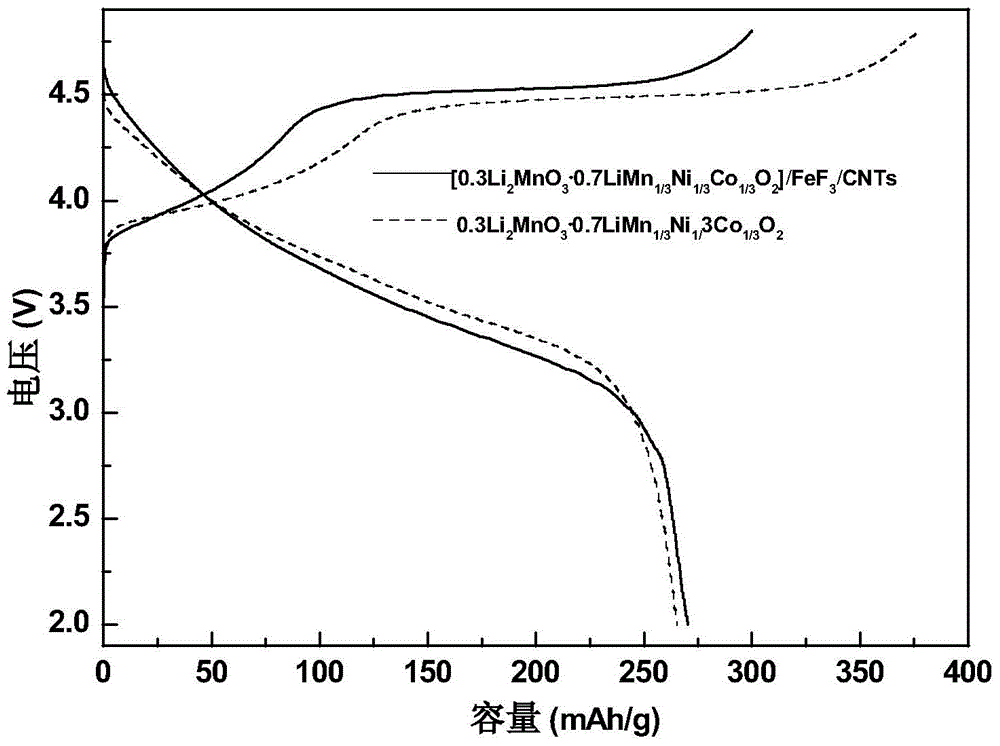

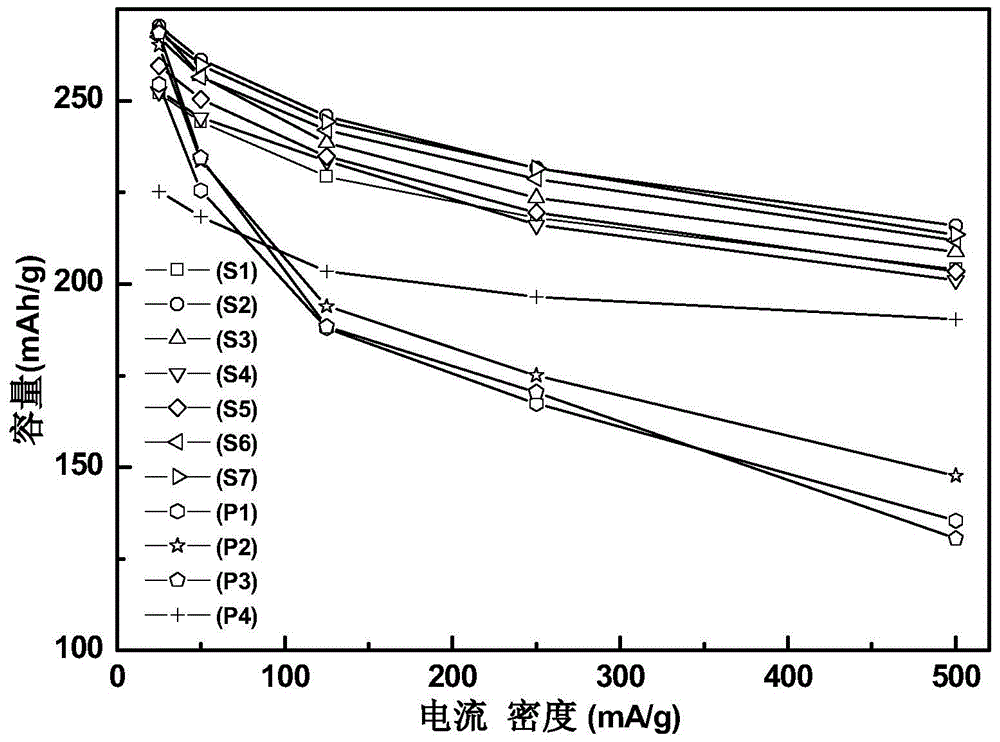

A lithium-rich manganese-based, mixed conductor technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as poor electronic conductivity and affect electrochemical performance, and achieve increased electronic conductivity and first Coulomb efficiency. The effect of high and superior magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

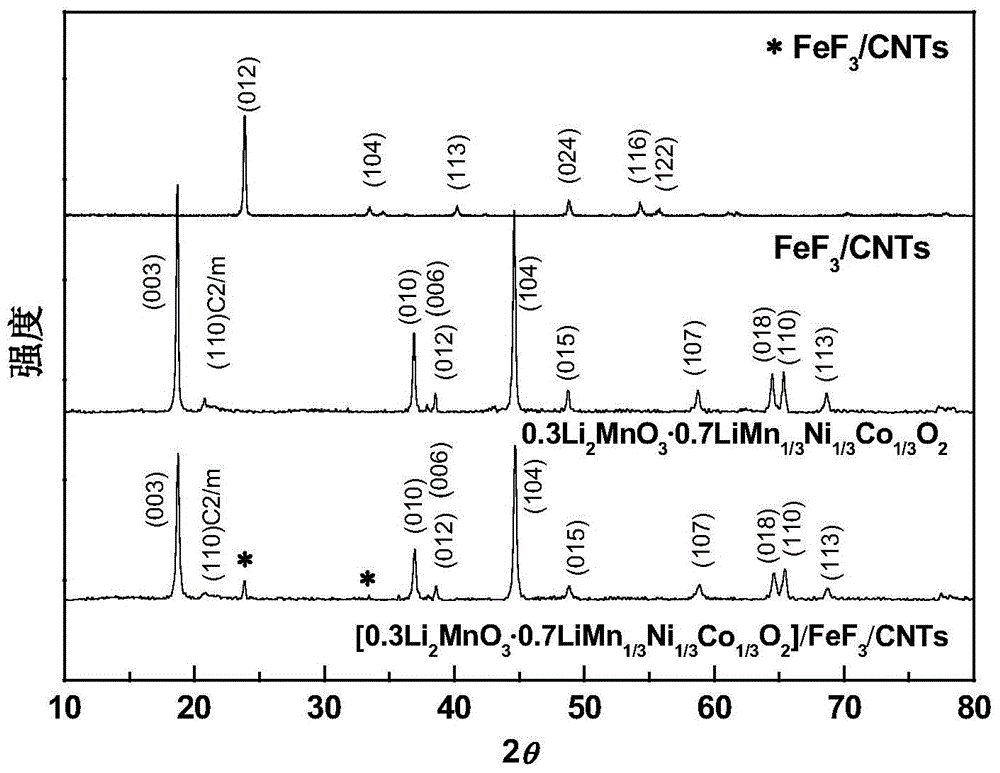

Embodiment 1

[0033] 11mol of lithium hydroxide, 4mol of manganese nitrate, 3mol of nickel nitrate and 3mol of cobalt nitrate were evenly mixed and dispersed in the carboxymethyl cellulose solution, and stirred until a suspension was formed; The viscous slurry was prepared by grinding at a speed of 1 / min for 2 hours; the above slurry was spray-dried by a spray dryer, the feed rate was controlled at 10mL / min, the inlet temperature was 320°C, and the outlet temperature was 120°C to prepare the precursor; The body was placed in a sintering furnace, and the temperature was raised to 950°C at a heating rate of 5°C / min, and kept for 10 hours to obtain a lithium-rich manganese-based solid solution 0.1Li 2 MnO 3 0.9LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 . Add 1 mol of ferric chloride and 3 mol of hydrogen fluoride into a sealed hydrothermal reaction kettle, raise the temperature to 160°C, react for 5h, filter with suction, wash, and dry at 130°C to obtain FeF 3 powder. The obtained manganese-based solid...

Embodiment 2

[0035] Lithium phosphate 13mol, manganese oxalate 3.33mol, nickel carbonate 2.33mol, cobalt carbonate 2.33mol were uniformly mixed and dispersed in the styrene-butadiene rubber solution, stirred until a suspension was formed; The viscous slurry was prepared by grinding at a speed of 1 / min for 5 hours; the above slurry was spray-dried by a spray dryer, the feed rate was controlled at 20mL / min, the inlet temperature was 200°C, and the outlet temperature was 80°C to prepare the precursor; The body was placed in a sintering furnace, and the temperature was raised to 950°C at a heating rate of 10°C / min, and kept for 20 hours to obtain a lithium-rich manganese-based solid solution 0.3Li 2 MnO 3 0.7LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 . Add 1 mol of ferric chloride and 3 mol of hydrogen fluoride into a sealed hydrothermal reaction kettle, raise the temperature to 240°C, react for 15 hours, filter with suction, wash, and dry at 90°C to obtain FeF 3 powder. The prepared manganese-based so...

Embodiment 3

[0037]15 mol of lithium hydroxide, 6.67 mol of manganese carbonate, 1.67 mol of nickel oxalate, and 1.67 mol of cobalt hydroxide were uniformly mixed and dispersed in the polyvinyl alcohol solution, stirred until a suspension was formed; the suspension was transferred to a roller mill tank, Grind at a speed of 500r / min for 20 hours to obtain a viscous slurry; use a spray dryer to spray dry the above slurry, control the feed rate to 50mL / min, the inlet temperature is 280°C, and the outlet temperature is 150°C to prepare the precursor; Place the precursor in a sintering furnace, raise the temperature to 950°C at a heating rate of 2°C / min, and keep it warm for 6 hours to obtain a lithium-rich manganese-based solid solution 0.5Li 2 MnO 3 0.5LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 . Add 1 mol of ferric nitrate and 3 mol of hydrogen fluoride into a sealed hydrothermal reaction kettle, raise the temperature to 200°C, react for 20 hours, filter with suction, wash, and dry at 100°C to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com