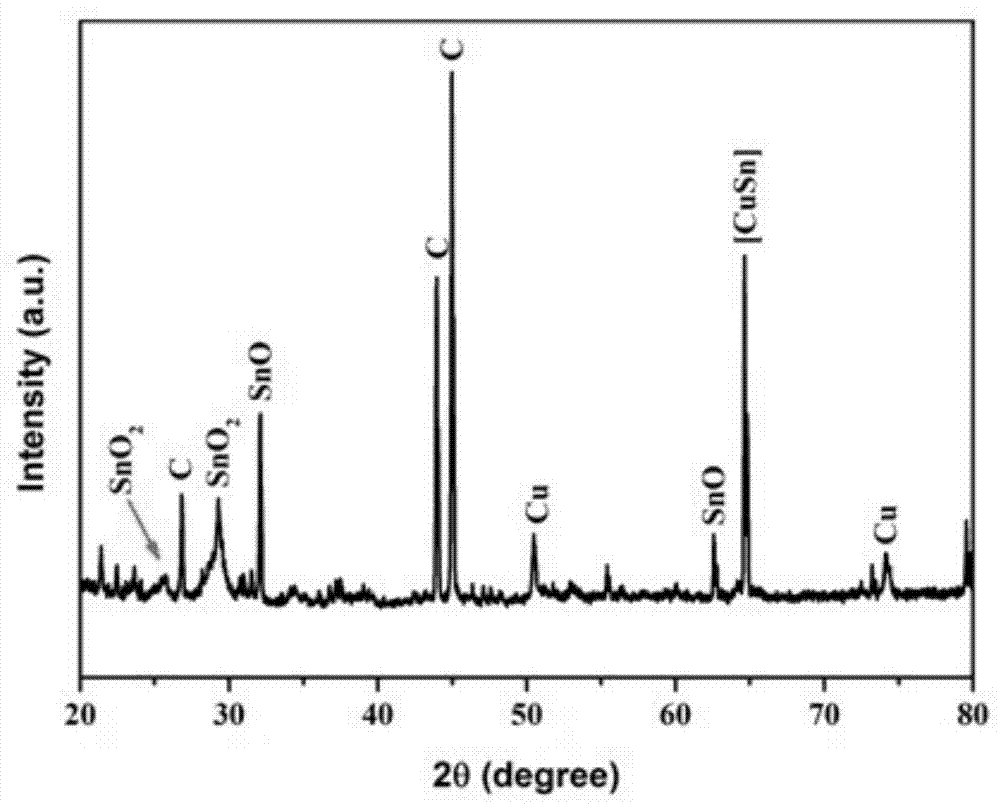

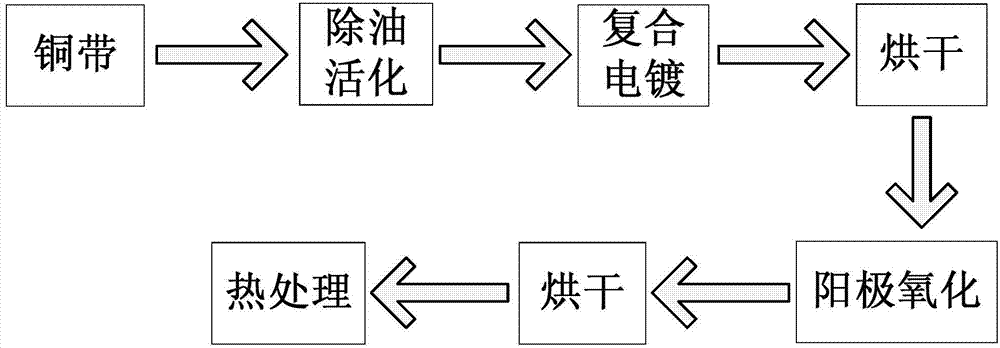

CNTS-doped tin oxide negative electrode material for lithium-ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in the field of CNTs-doped tin oxide negative electrode materials and its preparation, can solve the problems of high cost, serious environmental pollution, poor cycle performance, etc., and achieve cost controllable, low heat treatment temperature, and relatively The effect of capacity fade reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Copper strip was chosen as the electroplating substrate.

[0053] 1. Copper strip pretreatment

[0054] Degreasing solution:

[0055]

[0056] The activation formula and temperature used when preparing the activation solution are:

[0057] Sulfuric acid 40g / L;

[0058] Activation temperature Room temperature.

[0059] Add the pretreatment solution into the pretreatment tank of the continuous electroplating apparatus in sequence, and heat it to the specified temperature.

[0060] 2. Preparation of composite electroplating solution and anodizing solution

[0061] The formula and conditions used when preparing the composite tin plating solution are:

[0062]

[0063] The oxidation formula and conditions used when preparing the anodic oxidation solution are:

[0064]

[0065] 3. After preparing the plating solution, add it to the electroplating tank, and use constant current electroplating in an ultrasonic environment.

[0066] 4. Place the copper strip on t...

Embodiment 2

[0070] Preparation method: select the same copper strip as in Example 1, electroplate a layer of CNTs-doped metal tin layer with the thickness of the material electroplated in Example 1 in the same electroplating tin solution as Example 1, and pass through the same thickness as Example 1 The same anodic oxidation is not heat-treated, and it can be directly used as the negative electrode material of lithium-ion batteries.

Embodiment 3

[0072] Preparation method: take the copper strip, and electroplate a layer of CNTs-doped metal tin layer with the same thickness as the material electroplated in Example 1 in the same electroplating tin solution as in Example 1, without anodic oxidation and then adopt the same method as in Example 1. The same heat treatment temperature and heat treatment time are annealed to obtain the lithium ion battery negative electrode material.

[0073] Performance Testing

[0074] A sample was prepared as a comparative example in the following manner.

[0075] Purchase natural flake graphite, mix graphite, PVDF and acetylene black evenly according to the mass ratio of 8:1:1, add a certain amount of NMP, stir to make a slurry with appropriate viscosity, and use the scraper method to evenly attach the slurry to the surface of the copper foil. Make a negative electrode sheet.

[0076] The lithium-ion battery anode materials prepared in Example 1, Example 2, Example 3 and Comparative Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com