Cooking ware for induction cooker and production technology thereof

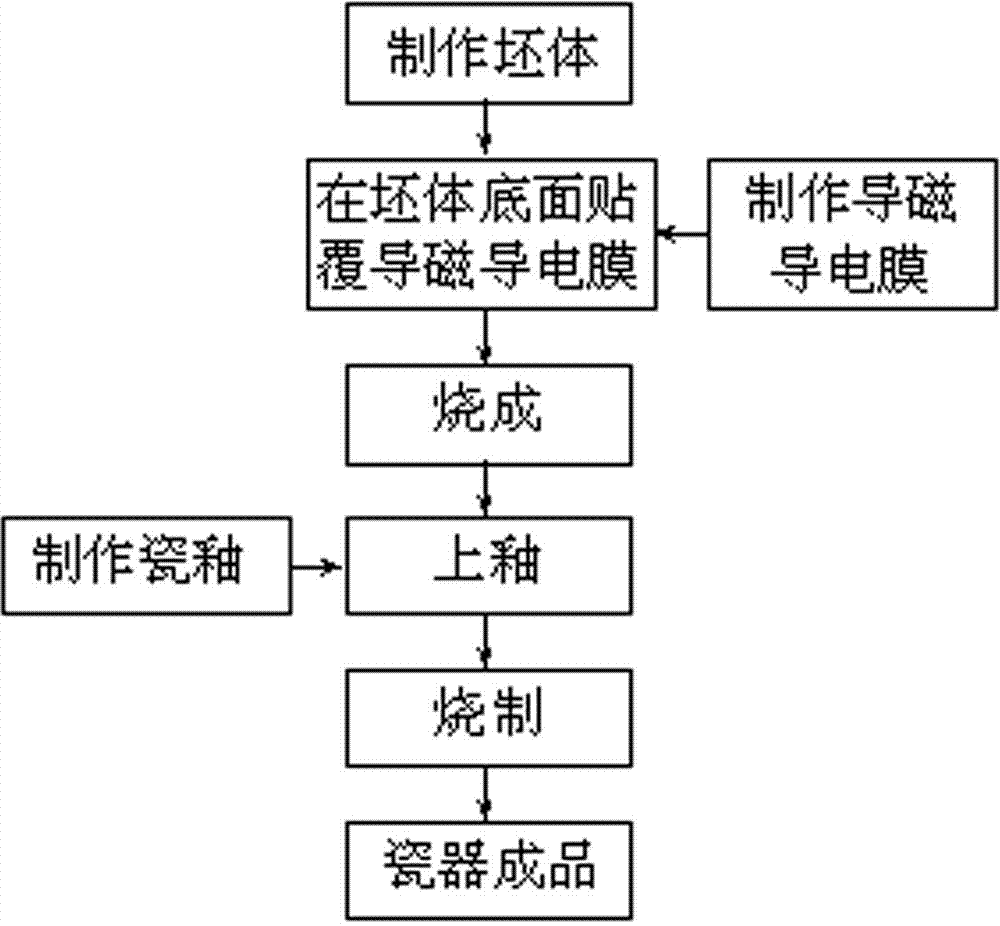

A production process and induction cooker technology, applied in the field of porcelain and its production process, can solve the problems of cooking food or water in an induction cooker, inconvenience, etc., and achieve the effects of good whiteness and light transmittance, fast heating, and good magnetic and electrical conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0018] First of all, the raw materials (calculated by mass fraction) for making green body, enamel and magnetic and conductive film are taken according to the following components:

[0019] 1) The green body contains the following components: kaolin 36%, quartz 60%, bone powder 0.6%, talc 0.3%, potassium feldspar 2.6% and spodumene 0.5%;

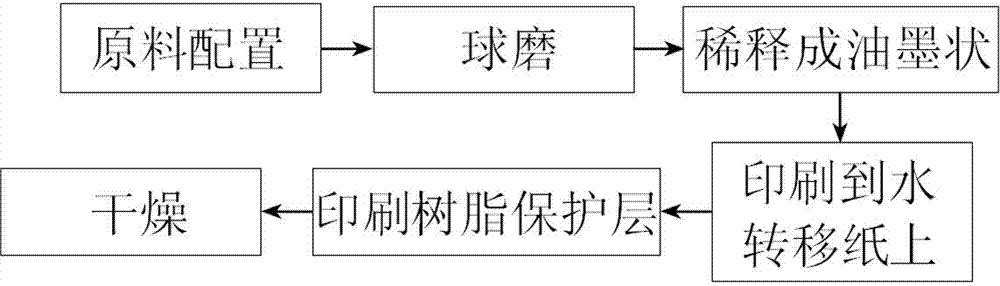

[0020] 2) The magnetic and conductive film contains: 35% silver oxide paste and 65% quartz powder, of which silver oxide paste contains 50% silver oxide;

[0021] 3) The composition of the enamel layer is: 32% kaolin, 42% quartz, 10% limestone, 3% talc, 6% potassium feldspar, 1% spodumene and 6% zinc oxide.

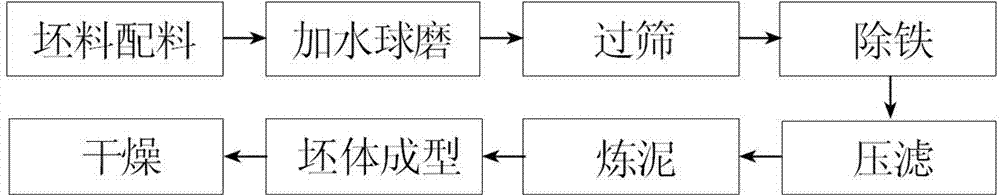

[0022] Next, water ball mill is added to make the raw material of the green body, and after sieving, iron removal, pressure filtration and mud refining, the green body is formed, and then dried to make the green body to be processed.

[0023] At the same time, the raw materials for making enamel are milled with water balls, and then si...

specific Embodiment 2

[0027] First of all, the raw materials (calculated by mass fraction) for making green body, enamel and magnetic and conductive film are taken according to the following components:

[0028] 1) The green body contains the following components: kaolin 56%, quartz 40%, bone powder 0.2%, talc 0.2%, potassium feldspar 3.2% and spodumene 0.4%;

[0029] 2) The magnetic and conductive film contains: 45% silver oxide paste and 55% quartz powder, of which silver oxide paste contains 60% silver oxide;

[0030] 3) The composition of the enamel layer is: kaolin 49%, quartz 28%, limestone 8%, talc 4%, potassium feldspar 4.8%, spodumene 1.5% and zinc oxide 4.7%.

[0031] Next, water ball mill is added to make the raw material of the green body, and after sieving, iron removal, pressure filtration and mud refining, the green body is formed, and then dried to make the green body to be processed.

[0032] At the same time, the raw materials for making enamel are milled with water balls, and th...

specific Embodiment 3

[0036] First of all, the raw materials (calculated by mass fraction) for making green body, enamel and magnetic and conductive film are taken according to the following components:

[0037] 1) The green body contains the following components: kaolin 42%, quartz 54%, bone meal 0.3%, talc 0.2%, potassium feldspar 3.1% and spodumene 0.4%;

[0038] 2) The magnetic and conductive film contains: 38% silver oxide paste and 62% quartz powder, of which silver oxide paste contains 52% silver oxide;

[0039] 3) The composition of the enamel layer is: 50% kaolin, 28% quartz, 6% limestone, 3% talc, 4% potassium feldspar, 2% spodumene and 7% zinc oxide.

[0040] Next, water ball mill is added to make the raw material of the green body, and after sieving, iron removal, pressure filtration and mud refining, the green body is formed, and then dried to make the green body to be processed.

[0041] At the same time, the raw materials for making enamel are milled with water balls, and then sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com