Macromolecular polymerization tantalum capacitor cathode preparation method

A technology of polymer polymerization and tantalum capacitors, which is applied in the direction of capacitor electrodes, capacitor parts, solid electrolytic capacitors, etc., can solve the problems of difficult polymerization to form a conductive polymer layer, and the increase of equivalent series resistance, so as to achieve tight combination and enhanced Infiltrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

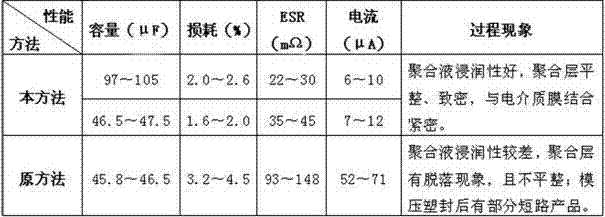

Examples

Embodiment 1

[0010] 1) Press the tantalum powder with a specific volume of 70000μFV / g into a tantalum compact according to the conventional method, and then sinter into the anode tantalum block according to the conventional method;

[0011] 2) Immerse the anode tantalum block in phosphoric acid solution to prepare Ta 2 o 5 Dielectric oxide film;

[0012] 3) Prepare the surface with Ta 2 o 5 The anode tantalum block of the dielectric oxide film is immersed in the pretreatment solution with a conductivity of 30-100μS / cm, and it is taken out at a speed of 1-2mm / min after immersion for 5 minutes; the pretreatment solution is prepared from the following volume percentage raw materials Composition: silane coupling agent 10%, glacial acetic acid 0.5%, water 89.5%;

[0013] 4) Polymerize the PEDOT conductive film on the surface of the pretreated anode tantalum block as the negative electrode according to the conventional method;

[0014] 5) Apply graphite and silver paste on the surface of th...

Embodiment 2

[0016] The steps are the same as in Example 1, wherein the immersion time in step 3) is 15 minutes, the silane coupling agent in the pretreatment liquid is 1%, the glacial acetic acid is 5%, and the water is 94%.

Embodiment 3

[0018] The steps are the same as in Example 1, wherein the immersion time in step 3) is 10 minutes, the silane coupling agent in the pretreatment solution is 10%, the glacial acetic acid is 5%, and the water is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com