Method for controlling operation of non-radial displacement sensor of bearingless permanent magnetic synchronous motor

A technology of permanent magnet synchronous motor and radial displacement, which is applied in the high-performance control of bearingless permanent magnet synchronous motor and the field of operation control of bearingless permanent magnet synchronous motor without radial displacement sensor, which can solve high-frequency signal extraction and signal filtering processing Problems such as complex process, difficult to accurately model, complex bearingless motor, etc., achieve the effect of improving system approximation accuracy, easy engineering implementation, and good generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

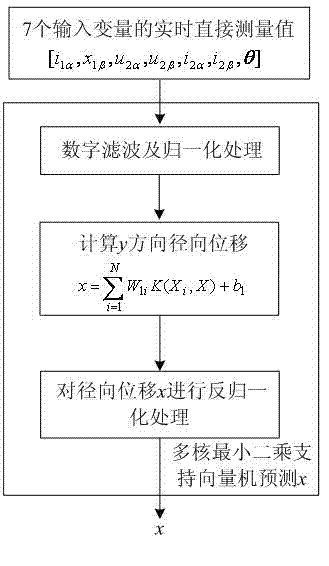

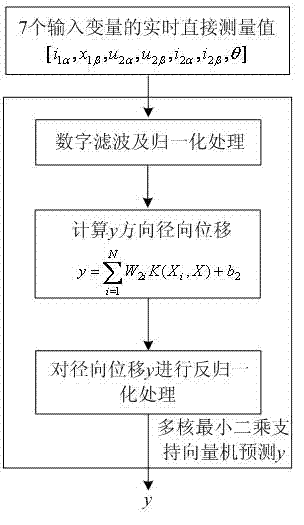

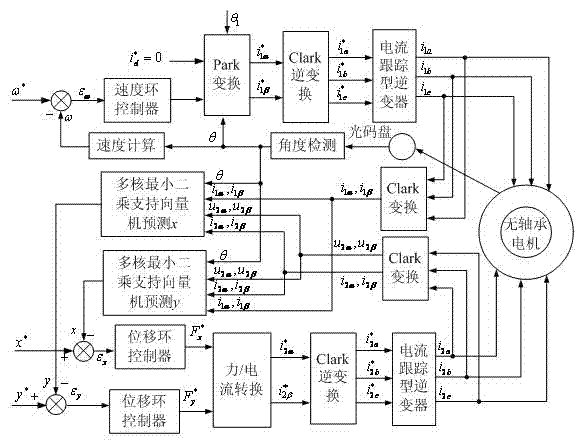

[0022] The embodiment of the present invention is: under the two-phase static coordinate system, the magnetic linkage of the suspension winding of the bearingless permanent magnet synchronous motor , Mathematical model and rotor radial displacement x , y vs. torque winding current i 1α 、i 1β , suspension winding voltage u 2α , u 2β , suspension winding current i 2α , i 2β and rotor angle θ The nonlinear mathematical model among them; design a multi-core least squares support vector machine, and construct a new equivalent kernel by linear combination of three kernel functions: polynomial kernel, exponential kernel and radial basis kernel; collect input data[ i 1α , i 1β , u 2α , u 2β , i 2α , i 2β , θ ] with output data x , y Perform preprocessing and normalization to form training samples, train the multi-core least squares support vector machine, adjust and determine the weight coefficients and thresholds of the support vector machine; construct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com