Organic resin laminate

An organic resin, laminate technology, applied in synthetic resin layered products, coatings, layered products, etc., can solve problems such as cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0232] Synthetic examples, examples and comparative examples are given below by way of illustration, not by way of limitation. All parts and percentages are by weight unless otherwise indicated. The viscosity is measured at 25° C. according to JIS Z8803. Mw refers to the weight average molecular weight measured by gel permeation chromatography using polystyrene as a standard.

[0233] [(2-A) Surface-coated composite oxide nanoparticle dispersion]

[0234] Surface-coated composite oxide nanoparticle dispersions as shown below were used as UV shielding agents.

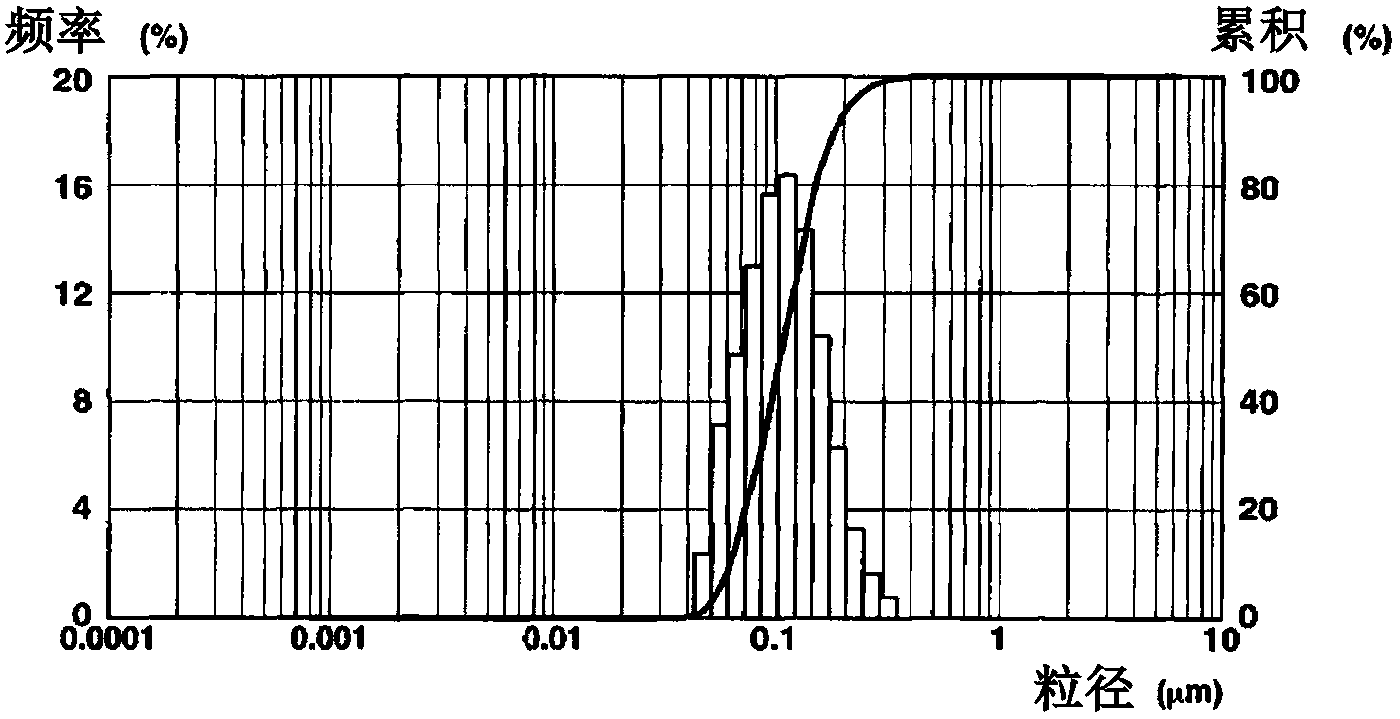

[0235] A-1: ZNTANB15wt%-E16 (2) from C.I.Kasei Co., Ltd (C.I.Kasei Co., Ltd) (adding silicon dioxide to zinc oxide nanoparticles prepared by DC arc plasma method , surface treated with methyltrimethoxysilane and dispersed in alcohol mixture with the help of dispersant, particle concentration: 15%, particle size distribution measured by Nanotrac UPA-EX150 (Nikkiso Co., Ltd.): figure 1 , average particle size (volume a...

Synthetic example 1

[0243] A 2-L flask was charged with 287 g (2.11 Si-mol) of methyltrimethoxysilane and cooled to a liquid temperature of approximately 10°C. After the flask was cooled, 211g of Snowtex O (Nissan Chemical Co., Ltd., water-dispersed silica gel, average particle size 15-20nm, SiO2 content of 20%) and 93g of 0.25N acetic acid aqueous solution were added dropwise so that the internal temperature would not exceed 40 °C, allow the hydrolysis to proceed. After the dropwise addition, the solution was stirred for 1 hour below 40° C., followed by 3 hours at 60° C. to allow complete hydrolysis.

[0244] Thereafter, 300 g of cyclohexanone was poured into the reaction mixture, heated under atmospheric pressure until the liquid temperature reached 92° C., thereby distilling off methanol produced by hydrolysis, and allowing condensation to proceed. 400 g of isopropanol diluent, 1.6 g of acetic acid and 1.6 g of 25% aqueous tetramethylammonium hydroxide (TMAH) were added to the reaction mixtur...

Synthetic example 2-9

[0247] Eight silicone resin coating compositions (II-b) to (II-i) were prepared as in Synthesis Example 1, except for the type and amount of the surface-coated composite oxide nanoparticle dispersion, and the amount of leveling agent have changed, as shown in Table 2.

[0248] [Synthesis of compounds having nitrogen and alkoxysilyl groups in the molecule]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com