Hydrous cutting fluid for slicing silicon ingot

A cutting fluid and slicing technology, applied in grinding/polishing equipment, base materials, stone processing equipment, etc., can solve the problems of silicon wafer surface flatness degradation and insufficient effect, and achieve excellent reaction inhibition and foam suppression Excellent performance and high cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

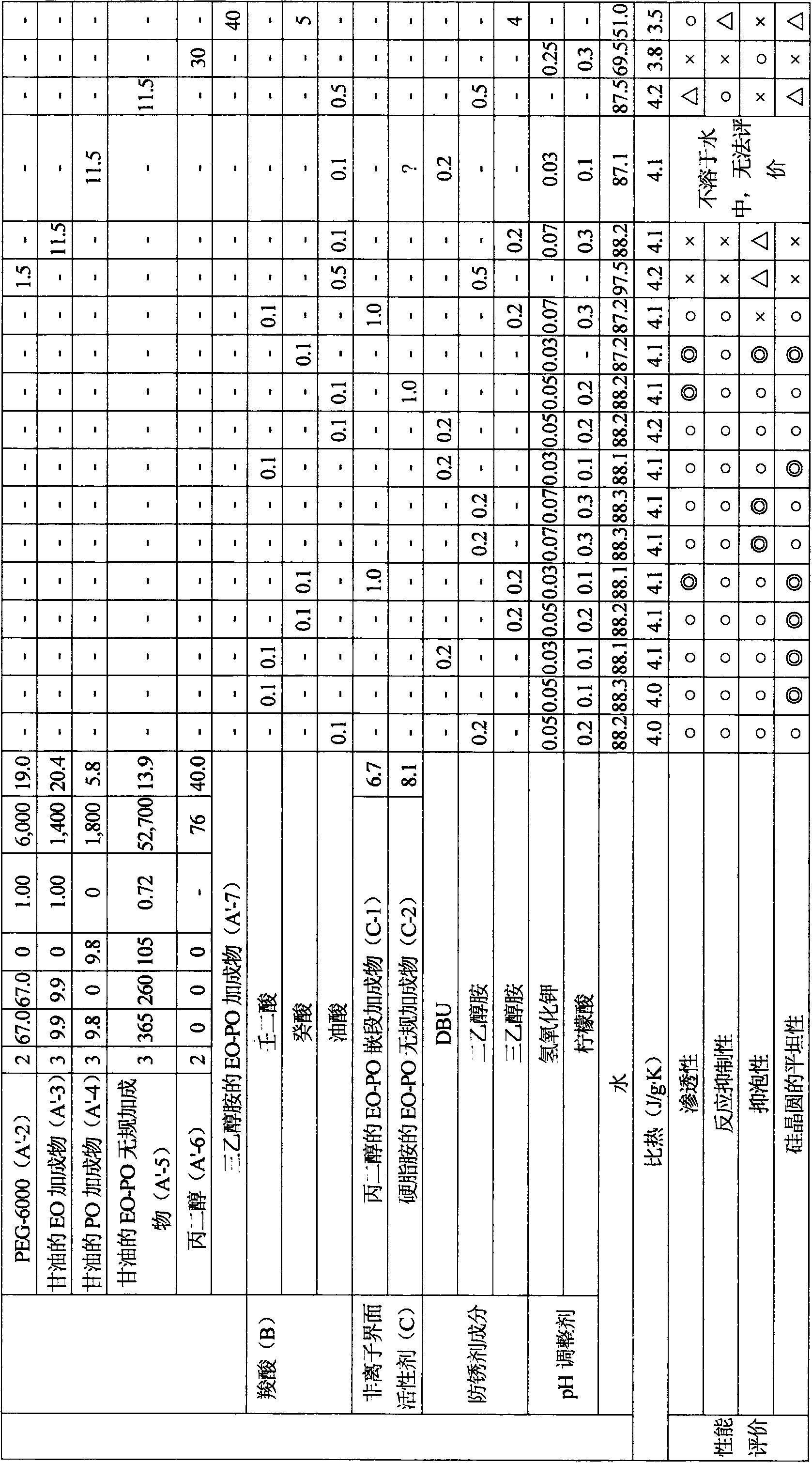

Examples

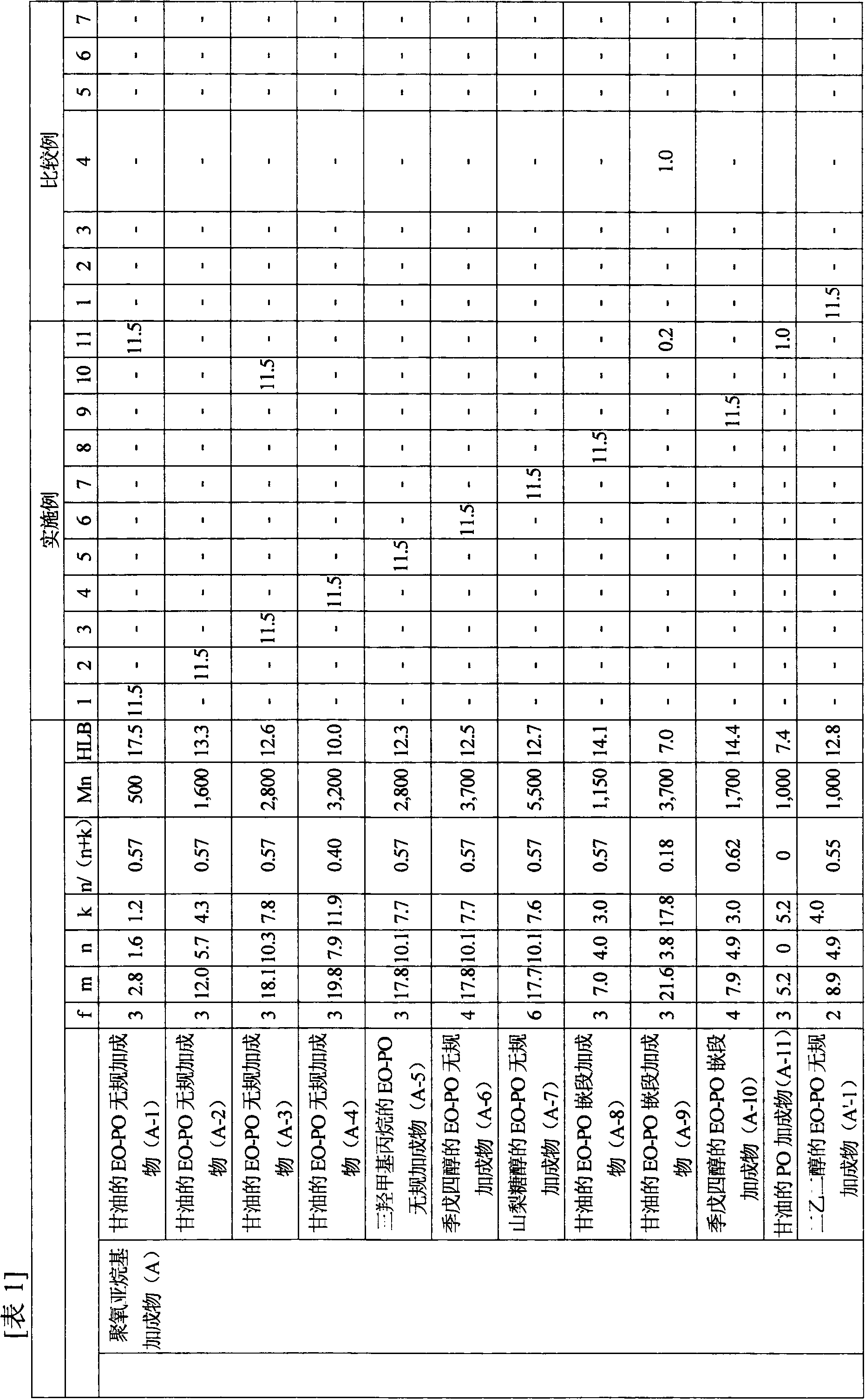

manufacture example 1

[0100] Production Example 1

[0101] Add 92 parts of glycerin and 0.05 parts of sodium hydroxide to a pressurized reaction device made of stainless steel, and replace with nitrogen, then mix 204 parts of ethylene oxide and 204 parts of propylene oxide at 120°C to 140°C for about 4 hours Hydraulic indentation.

[0102]Further react at this temperature for 10 hours to obtain the EO-PO random adduct (A-1) of glycerol of the present invention (f=3; m=2.8; n=1.6; k=1.2; n / (n+ k) = 0.57; number average molecular weight 500; HLB = 17.5).

[0103] In addition, the number average molecular weight is the molecular weight obtained by gel permeation chromatography (GPC).

manufacture example 2

[0104] Production Example 2

[0105] In Production Example 1, except that glycerol was set to 29 parts, ethylene oxide was set to 238 parts, and propylene oxide was set to 238 parts, the same operation as Production Example 1 was carried out to obtain the EO-PO random adduct (A-2) of glycerol (f=3; m=12.0; n=5.7; k=4.3; n / (n+k)=0.57; number average molecular weight is 1,600; HLB= 13.3).

manufacture example 3

[0106] Production Example 3

[0107] In Production Example 1, except that glycerin was set to 16.4 parts, ethylene oxide was set to 241 parts, and propylene oxide was set to 241 parts, the same operation as Production Example 1 was carried out to obtain the EO-PO random adduct (A-3) of glycerol (f=3; m=18.1; n=10.3; k=7.8; n / (n+k)=0.57; number average molecular weight is 2,800; HLB= 12.6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com