Digital cold-stamping gold film and production process thereof

A cold bronzing film and digital technology, applied in the direction of layered products, synthetic resin layered products, copying/marking methods, etc., can solve the problems of high operation risk, high pollution, high use cost, etc., and achieve less process flow and easier operation The effect of simplicity and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

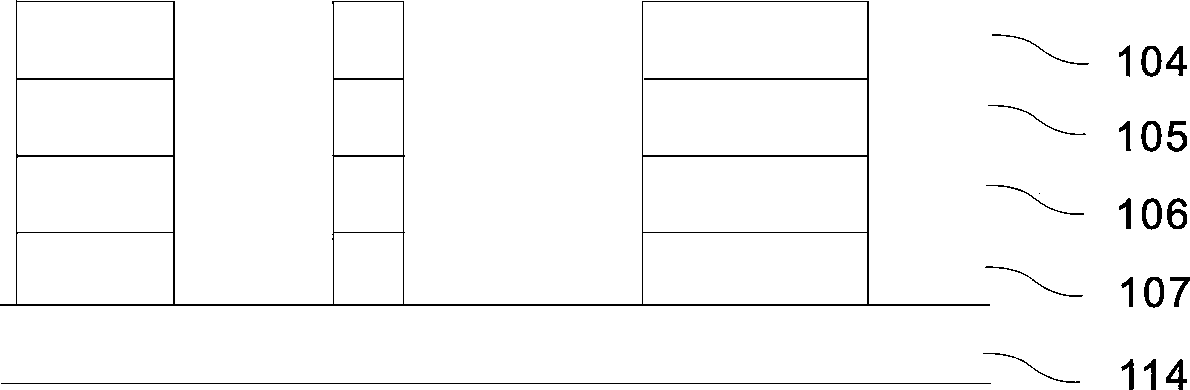

[0074] Embodiment one, see Figure 4 , is shown as the overall structure schematic diagram of an embodiment of the digital cold stamping film of the present invention, and this bronzing film comprises: information carrier 162, release layer 103 on the first surface of information carrier 162, bonded to release layer 103 A pressure-sensitive adhesive layer 102, face paper 101 covered on the A pressure-sensitive adhesive layer 102, B pressure-sensitive adhesive layer 107 on the second surface of the information carrier 162, silicone oil layer 108 bonded to the B pressure-sensitive adhesive layer 107 , and the base paper 109 covered on the silicone oil layer 108.

[0075] Wherein, the information carrier 162 includes a three-layer structure: a film carrier 106 , a specular reflection layer 105 on the film carrier 106 , and a surface layer 104 bonded to the specular reflection layer 105 .

[0076] From top to bottom, it is face paper 101, A pressure-sensitive adhesive layer 102, ...

Embodiment 2

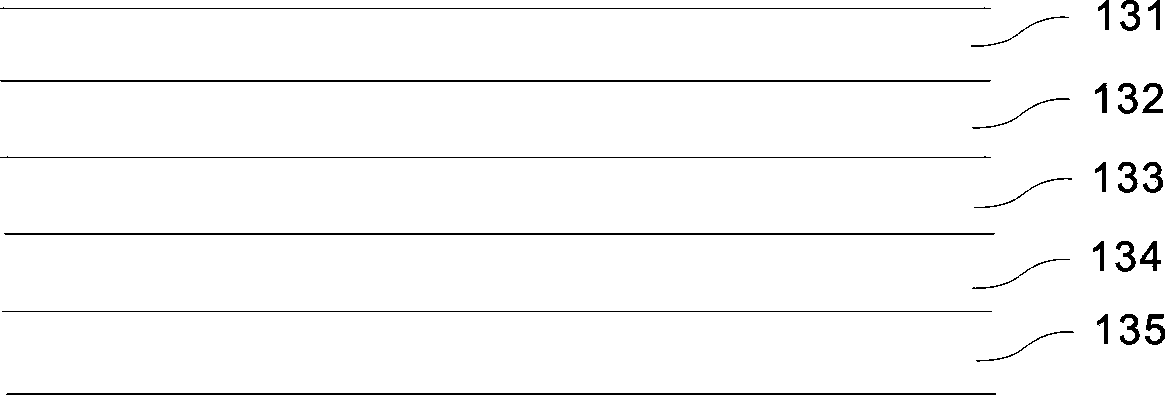

[0088] Embodiment two, see Figure 5 , is shown as the overall structure schematic diagram of another embodiment of digital cold stamping film of the present invention, and this bronzing film comprises: information carrier 162, the release layer 103 on the first surface of information carrier 162, is bonded on the release layer 103 The A pressure-sensitive adhesive layer 102, the face paper 101 covered on the A pressure-sensitive adhesive layer 102, the B pressure-sensitive adhesive layer 107 on the second surface of the information carrier 162, the silicone oil layer bonded to the B pressure-sensitive adhesive layer 107 108, and the base paper 109 covered on the silicone oil layer 108.

[0089] Wherein, the information carrier 162 includes a three-layer structure: a film carrier 106 , a surface layer 104 on the film carrier 106 , and a specular reflection layer 105 bonded to the surface layer 104 .

[0090] From top to bottom are face paper 101, A pressure-sensitive adhesive...

Embodiment 3

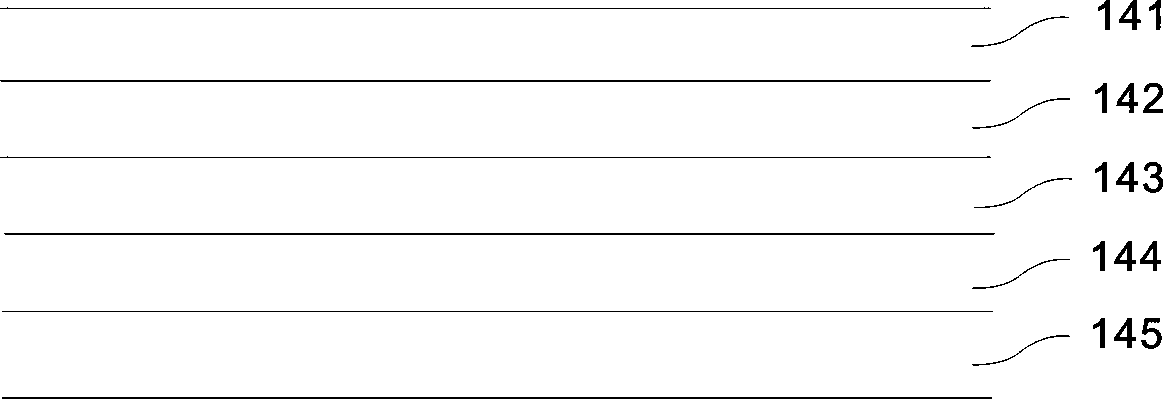

[0102] Embodiment three, see Image 6 , is shown as the overall structure schematic diagram of another embodiment of digital cold stamping film of the present invention, and this bronzing film comprises: information carrier 162, the release layer 103 on the first surface of information carrier 162, is bonded on the release layer 103 The A pressure-sensitive adhesive layer 102, the face paper 101 covered on the A pressure-sensitive adhesive layer 102, the B pressure-sensitive adhesive layer 107 on the second surface of the information carrier 162, the silicone oil layer bonded to the B pressure-sensitive adhesive layer 107 108, and the base paper 109 covered on the silicone oil layer 108.

[0103] Wherein, the information carrier 162 includes a two-layer structure: a film carrier 106 and a surface layer 104 on the film carrier 106 .

[0104] From top to bottom, there are surface paper 101, A pressure-sensitive adhesive layer 102, release layer 103, film carrier 106, surface la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| release force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com