Preparation of a microfluidic monolithic column chip and its application in Raman detection

A microfluidic chip and monolithic column technology is applied in the field of preparation of microfluidic monolithic column chips to achieve the effects of strong detection repeatability, easy preparation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

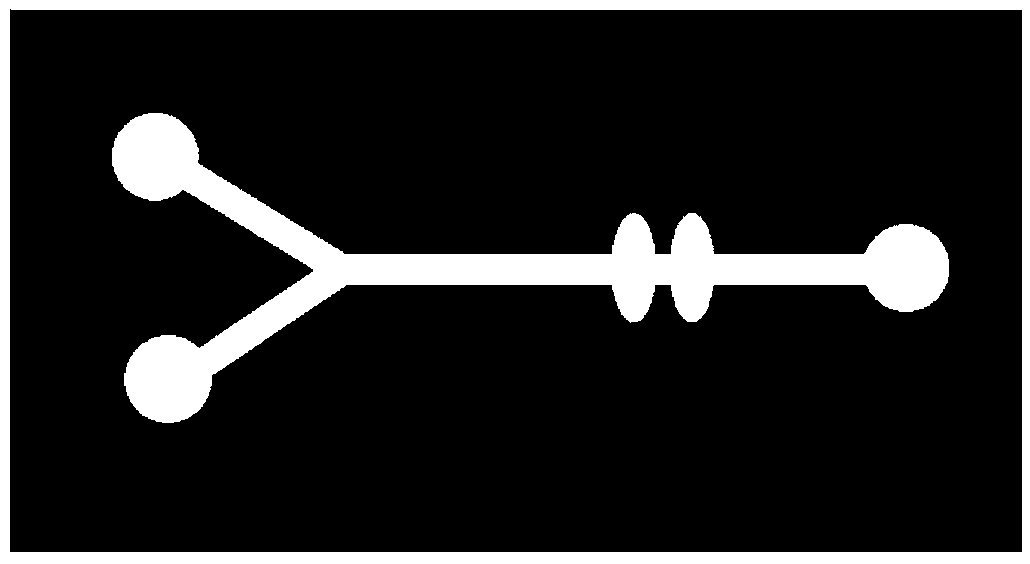

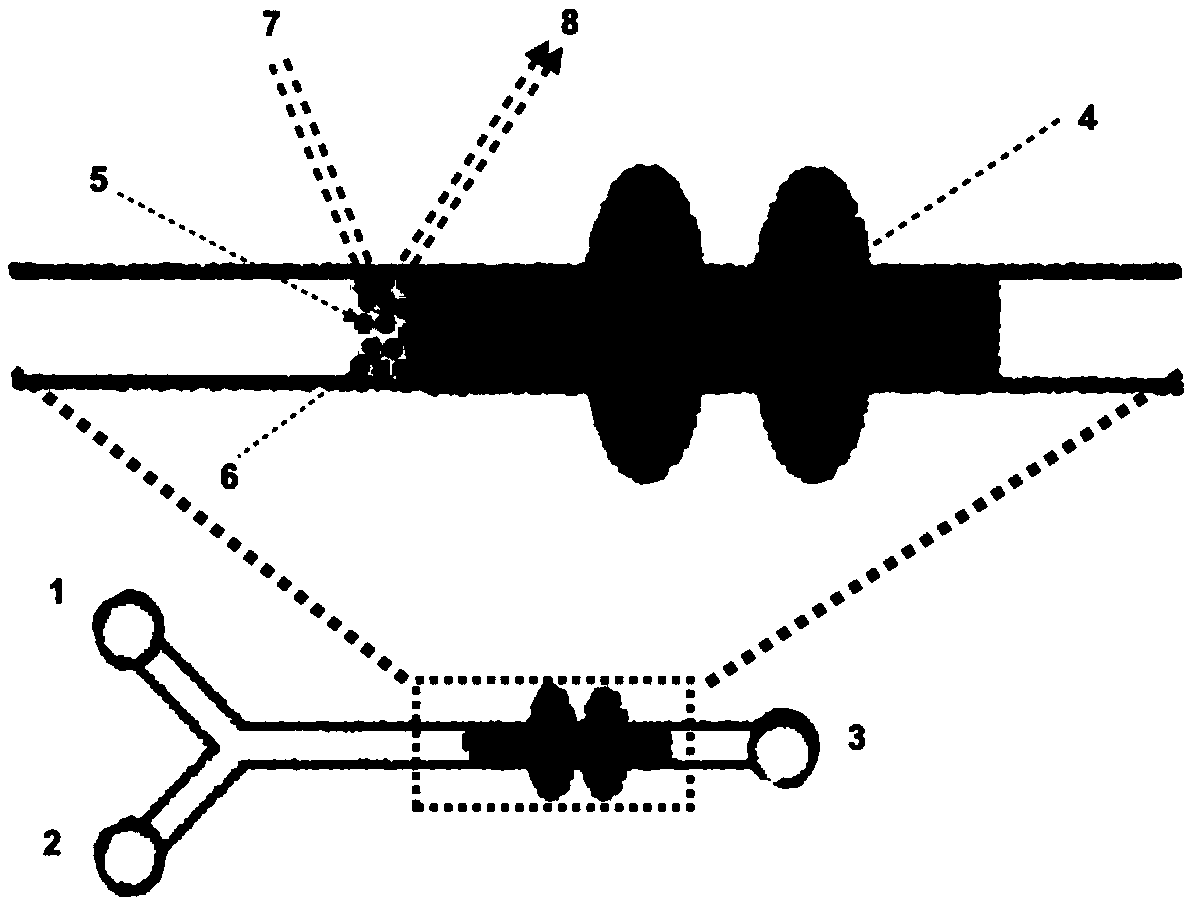

[0041] (a) Use AutoCAD computer drawing software to design the microfluidic pipeline drawing mask, and design two continuous vertical pipeline ellipses at the exposure place of the microfluidic chip, the long axis is 150-400 μm, and the short axis is 50-200 μm. The technology is different from other microfluidic chips, which usually adopt a rectangular pipeline design. The pipeline design is as follows: figure 1 shown.

[0042] (b) Fabrication of PDMS microfluidic chips using soft lithography standard microfabrication techniques.

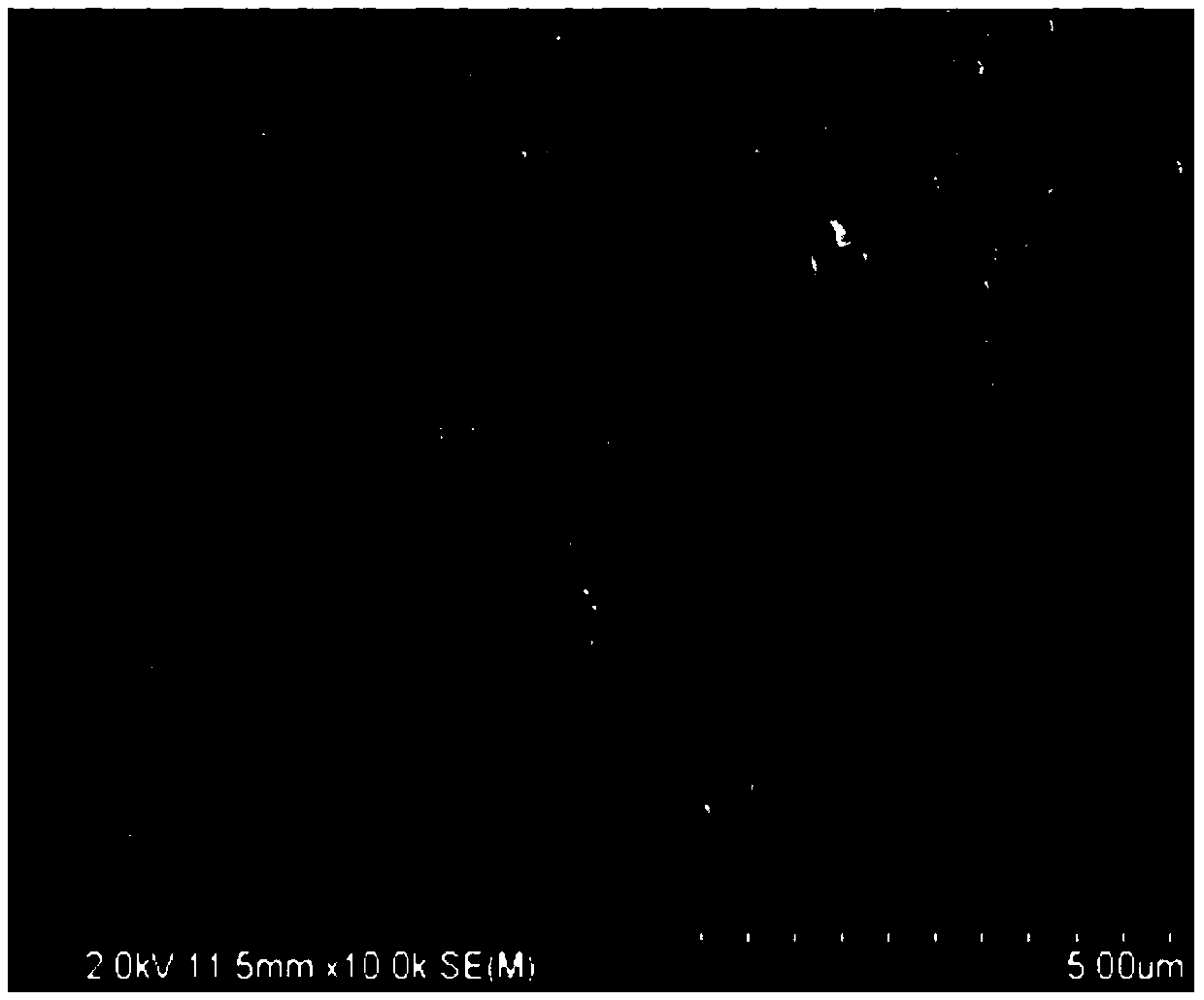

[0043](c) Preparation of monolithic column solution, mix monomer (GMA), cross-linking agent (EGDMA), and pore-forming agent (DOP) in a weight ratio of 2:1:7, and then add the above-mentioned 2 % photoinitiator (DMPA), prepare a porous monolithic column solution, ultrasonicate the mixture for 5-20 minutes, then pass nitrogen gas into the monolithic column solution for 5-30 minutes to remove oxygen in the solution, and finally place the monolithic co...

Embodiment 2

[0053] (a) Using AutoCAD computer drawing software to design the microfluidic pipeline drawing mask, the pipeline design is as follows figure 1 As shown, the pipeline design of the exposure area of the microfluidic chip is an ellipse with two continuous vertical pipelines, the long axis is 150-400 μm, and the short axis is 50-200 μm. This technology is different from other microfluidic chips that usually use rectangular pipeline design.

[0054] (b) Fabrication of PDMS chips using soft lithography standard microfabrication techniques.

[0055] (c) Preparation of monolithic column solution, mix monomer (GMA), cross-linking agent (EGDMA), and pore-forming agent (DOP) in a weight ratio of 3:2:5, and then add the above-mentioned 4% of the total weight of the mixture A photoinitiator (DMPA) was used to prepare a porous monolithic column solution, and the mixed solution was ultrasonicated for 5-20 minutes, and then nitrogen gas was passed through the monolithic column solution for...

Embodiment 3

[0065] (a) Using AutoCAD computer drawing software to design the microfluidic pipeline drawing mask, the pipeline design is as follows figure 1 As shown, the pipeline design of the exposure place of the microfluidic chip is an ellipse with two continuous vertical pipelines, the long axis is 150-400 μm, and the short axis is 50–200 μm. This technology is different from other microfluidic chips that usually use rectangular pipeline design. .

[0066] (b) Fabrication of PDMS chips using soft lithography standard microfabrication techniques.

[0067] (c) Preparation of the monolithic column solution, mix the monomer (GMA), cross-linking agent (EGDMA), and pore-forming agent (DOP) in a weight ratio of 3:6:11, and then add the above-mentioned 4.5% of the total weight of the mixture % photoinitiator (DMPA), prepare a porous monolithic column solution, ultrasonicate the mixture for 5-20 minutes, then pass nitrogen gas into the monolithic column solution for 5-30 minutes to remove oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com