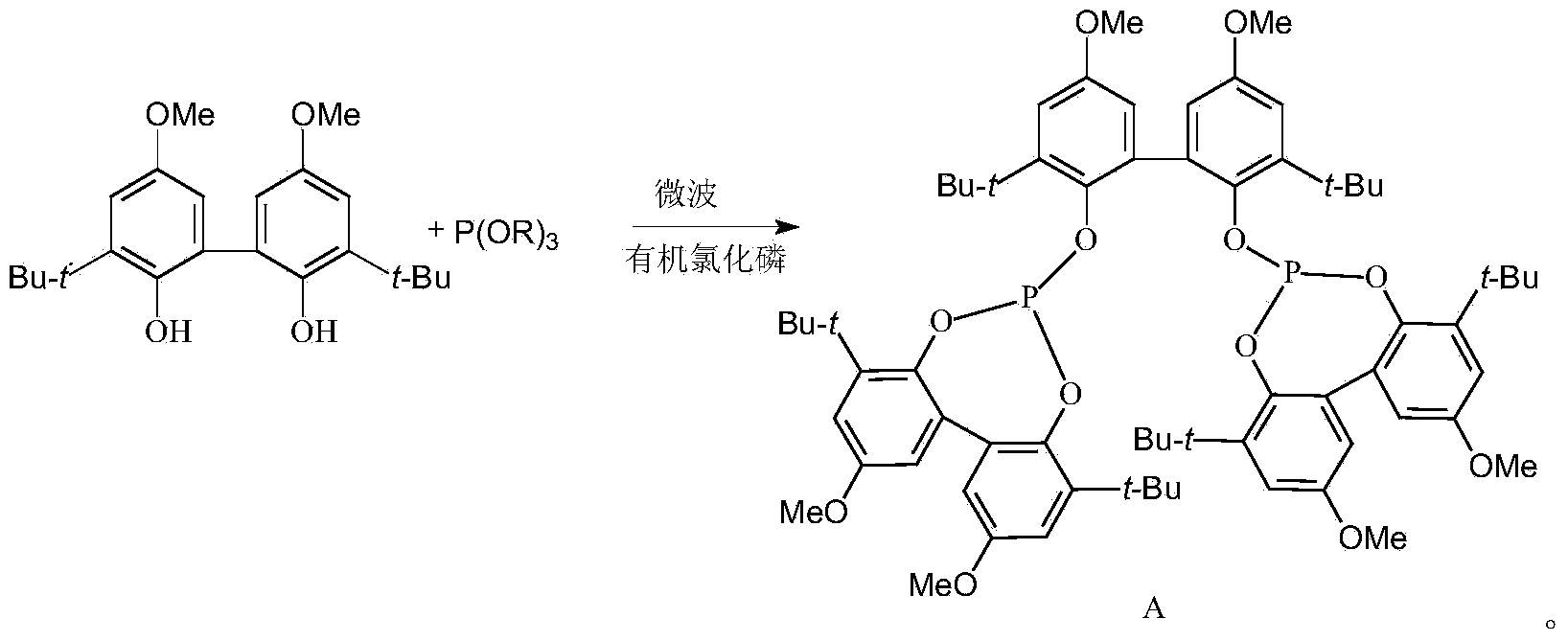

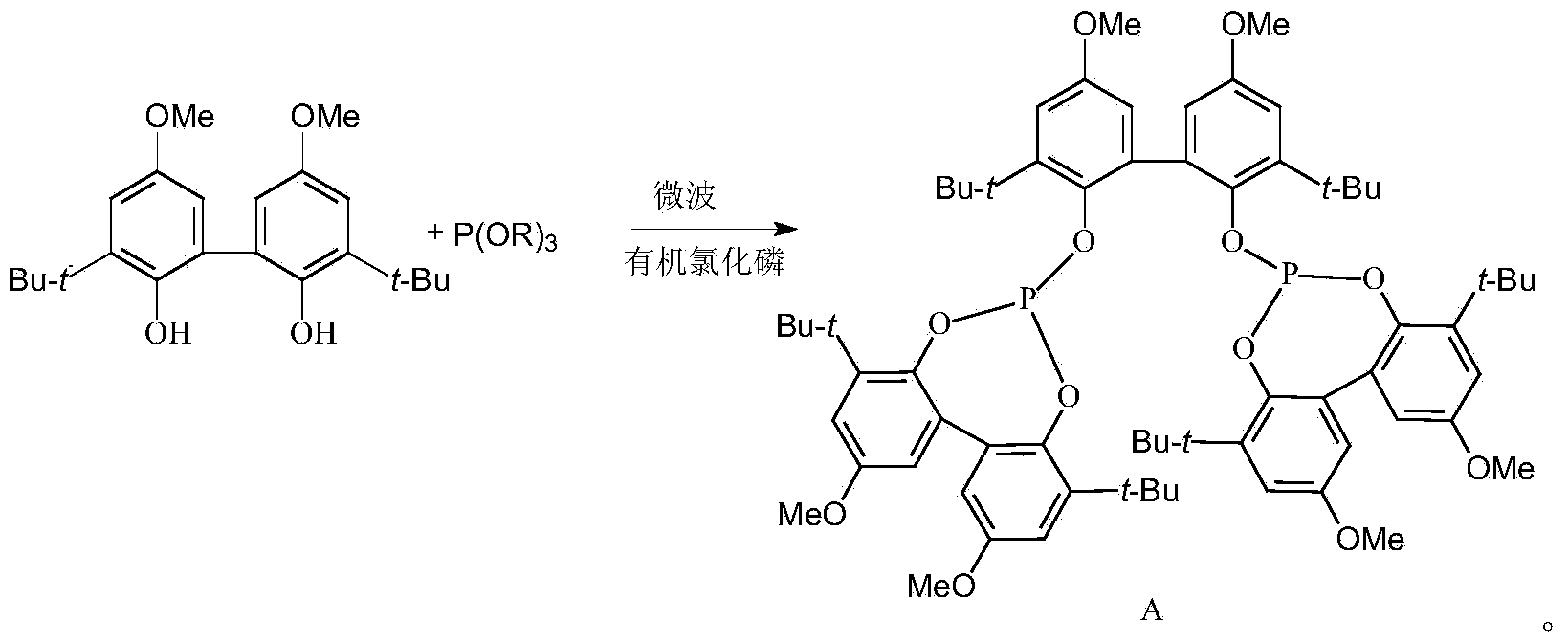

Microwave synthesis method for tri(3,3'-di-tert-butyl-5,5'-dimethoxy-2,2'-diphenol) biphosphite

A technology of trialkyl phosphite and bisphosphite, which is applied in the field of microwave synthesis of bisphosphite triester to achieve the effects of less by-products, high product yield and simple post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 14.5 grams of triethyl phosphite, 37.4 grams of 3,3'-di-tert-butyl-5,5'-dimethoxy-2,2'-biphenol and 2.7 grams of diphenyl phosphorus chloride catalyst In the microwave reaction device, after mixing and stirring evenly, react under the microwave radiation with a power of 200w for 25 minutes. After the reaction is completed, the reaction crude product is recrystallized with a mixed solvent of toluene and n-hexane to obtain the product. And HPLC analysis and verification, it is bisphosphite tris(3,3'-di-tert-butyl-5,5'-dimethoxy-2,2'-biphenol) ester with a yield of 90% (yield The rate is calculated based on 3,3'-di-tert-butyl-5,5'-dimethoxy-2,2'-biphenol).

Embodiment 2

[0022] 46.7 grams of triethyl phosphite, 37.4 grams of 3,3'-di-tert-butyl-5,5'-dimethoxy-2,2'-biphenol and 1.0 grams of phenyl phosphorus dichloride catalyst In a microwave reaction device, mix and stir evenly and react under microwave radiation with a power of 300w for 20 minutes. After the reaction is completed, the crude product is recrystallized with toluene and n-hexane to obtain the product. Liquid chromatography analysis verification, is bisphosphite tris (3,3'-di-tert-butyl-5,5'-dimethoxyl-2,2'-biphenol) ester, yield 89% (yield in 3,3'-di-tert-butyl-5,5'-dimethoxy-2,2'-biphenol as the basis for calculation).

Embodiment 3

[0024] 25.4 grams of trimethyl phosphite, 37.4 grams of 3,3'-di-tert-butyl-5,5'-dimethoxy-2,2'-biphenol and 6.2 grams of diphenyl phosphorus chloride catalyst In a microwave reaction device, mix and stir evenly and react under microwave radiation with a power of 500w for 15 minutes. After the reaction is completed, the reaction crude product is recrystallized with a mixed solvent of ethyl acetate and petroleum ether to obtain the product. Phosphorus spectrum and HPLC analysis verification, bisphosphite tris(3,3'-di-tert-butyl-5,5'-dimethoxy-2,2'-biphenol) ester, yield 91% (The yield is calculated based on 3,3'-di-tert-butyl-5,5'-dimethoxy-2,2'-biphenol).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com