Dental implant

A technology for dental implants and implants, applied in dentistry, dental implants, dental prosthetics, etc., can solve the problems of weakening the bonding ability of implants and surrounding connective tissue, adverse patient recovery, and adhesion of surrounding bacteria, and achieves the promotion of platelets. Adhesion and activation, accelerates good healing, prevents bacterial invasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

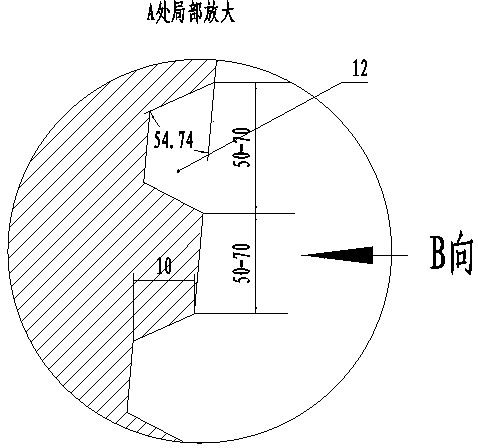

[0023] Embodiment 1, adopt photolithography technology, design the same mask plate as etched groove width and pitch, control the width and the pitch of the groove on the silicon plate through the mask plate, control the groove depth on the silicon plate by etching time, Realize multiple microgrooves evenly distributed at equal intervals on the surface of the smooth collar of the implant: the width is 60 μm, the groove spacing is 60 μm, and the depth is 10 μm. °, a 200nm titanium (Ti) coating was sprayed on the groove surface by magnetron sputtering technology.

Embodiment 2

[0024] Embodiment 2, adopt photolithography technology, design the mask plate with identical width and pitch of etched groove, control the width and the pitch of the groove on the silicon plate through the mask plate, control the groove depth on the silicon plate by etching time, Realize multiple microgrooves evenly distributed at equal intervals on the surface of the smooth collar of the implant: the width is 60 μm, the groove spacing is 60 μm, and the depth is 10 μm. °, a 200nm titanium nitride (TiN) coating was sputtered on the groove surface by magnetron sputtering technology.

Embodiment 3

[0025] Embodiment 3, adopt photolithography technology, design the mask plate with identical width and pitch of etched groove, control the width and the pitch of the groove on the silicon plate through the mask plate, control the groove depth on the silicon plate by etching time, Realize multiple micro-grooves evenly distributed at equal intervals on the surface of the smooth collar of the implant: width 50 μm, groove spacing 100 μm, depth 13 μm, the longitudinal section of the groove is an inverted trapezoid, and the angle between the side wall of the groove and the surface of the collar is 54.74 °, a 300nm titanium nitride (TiN) coating was sputtered on the groove surface by magnetron sputtering technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com