Improved method for resolving ammonium salt in acrylonitrile non-ammonium-sulfate process

A technology of acrylonitrile and ammonium sulfate, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high material consumption and high energy consumption, and achieve the effects of reducing consumption, reducing energy consumption and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

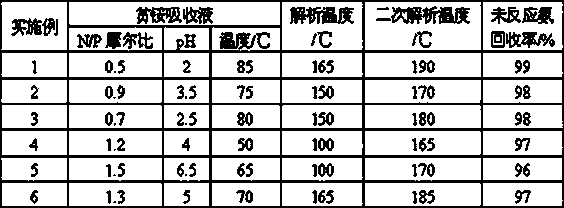

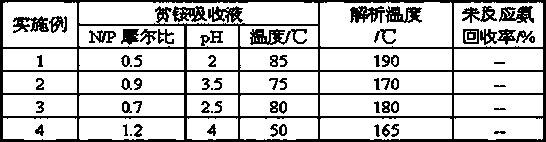

Embodiment 1~6

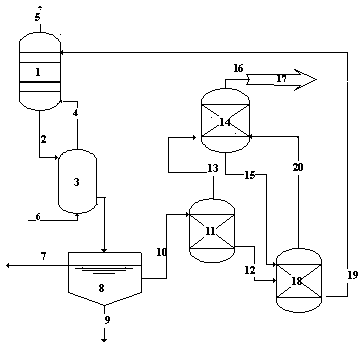

[0015] Embodiment 1-6 presses figure 1 Shown flow process operation, acrylonitrile reaction gas contacts and absorbs unreacted ammonia in quick cooling tower 1 and poor ammonium absorption liquid 12 and obtains reaction gas 5 and rich ammonium absorption liquid 2 without ammonia, and rich ammonium absorption liquid 2 is in stripping tower 3 After being stripped to light organic components 4 by stripping gas 5, it enters a special oil-water separation device 8 to remove light organic components 7 and heavy components such as catalysts and polymers 9 to obtain ammonium-rich absorption liquid 10, and then enters a desorption tower 11 for desorption to obtain Crude ammonia gas stream 13 and ammonium dihydrogen phosphate crystal 12, ammonium dihydrogen phosphate crystal enters secondary analysis tower 18 and dissolves in ammonia rectification tower still liquid 15 to obtain diammonium hydrogen phosphate absorption liquid, and further analysis obtains crude ammonia gas stream 20 poor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com