MEMS-based interdigital gap beam structure energy collector and manufacturing method thereof

The technology of an energy collector and a manufacturing method, which is applied in the field of interdigital gap beam structure energy collectors, can solve the problems of mass production constraints of the energy collector and the preparation of PZT thin films, etc., so as to improve the energy output efficiency and the output energy efficiency. , the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

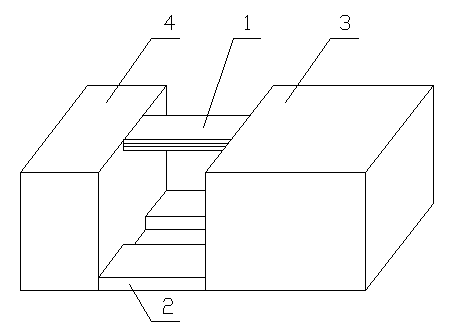

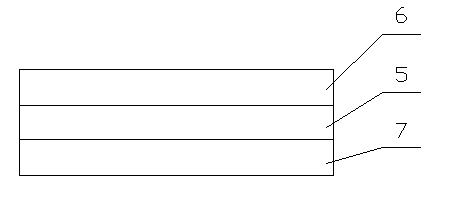

[0023] A MEMS-based energy harvester with an interdigitated gap beam structure, which consists of: a top layer PZT composite membrane beam 1, with two bottom supporting silicon beams 2 below the top layer PZT composite membrane beam, and the top layer PZT composite membrane beam The two ends of the beam and the bottom supporting silicon beam are respectively connected to the mass block 3 and the fixed block 4; wherein, the top layer PZT composite membrane beam includes a PZT beam layer 5, and an upper layer connected to the upper and lower layers of the PZT beam layer respectively. Metal electrode 6 and lower metal electrode 7.

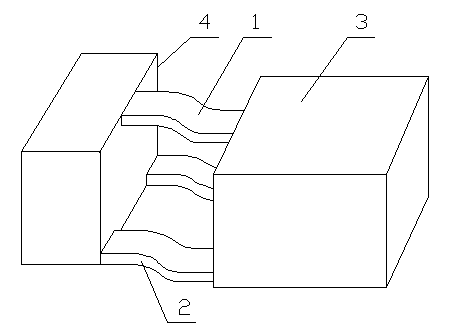

[0024] When the device vibrates, the beam undergoes S-shaped bending (attached image 3 ) and pure bend (with Figure 4 ), when S-shaped bending, due to the different materials, the stress of the upper and lower beams is different, and the bending degree is also different. The PZT beam has a greater bending degree, resulting in an increase in the amo...

Embodiment 2

[0026] MEMS-based interdigitated gap beam structure energy collector described in embodiment 1, the sum of the width of the top layer PZT composite film beam and the width of the two bottom supporting silicon beams is equal to the width of the mass block; The width of the gap between the two bottom supporting silicon beams is the same as the width of the top layer PZT composite membrane beam.

Embodiment 3

[0028]A MEMS-based method for manufacturing an energy harvester with an interdigitated gap beam structure. First, using the PZT thin film preparation method and the MEMS bulk silicon method, a three-dimensional gap cavity structure is etched on a rectangular silicon substrate, and the upper and lower two-layer structures Form a void cantilever beam structure, and prepare a three-dimensional void silicon beam structure with a top PZT composite membrane beam and two bottom supporting silicon beams; after that, convert most of the mechanical energy generated by the vibration source to the top PZT composite membrane into effective electrical energy output, and improve Response frequency; at the same time, by adjusting the shape of the mass block on the free end of the top PZT composite membrane beam, the distance between the top PZT composite membrane beam and the bottom supporting silicon beam is adjusted to realize the resonant frequency range of the interdigitated beam structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com