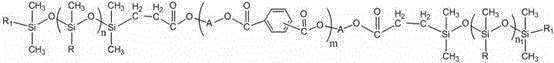

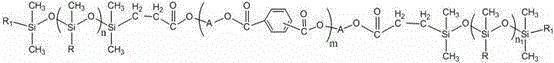

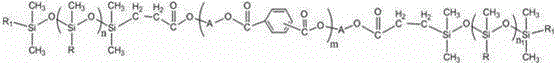

A kind of polysiloxane-polyarylate block copolymer and its preparation and application

A technology of block copolymer and polysiloxane, which is used in transportation and packaging, special packaging items, types of packaging items, etc., to achieve a wide range of applications, mild and easy-to-control reaction conditions, and prolonged coagulation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of olefin-terminated polyarylate: First, add 0.03mol (6.84g) of bisphenol A, 0.066mol (2.64g) of NaOH, 80ml of deionized water and 0.051g of phase transfer catalyst into a three-necked flask, and stir to dissolve bisphenol A It forms an inorganic phase in water. Dissolve 0.015mol (3.03g) of terephthaloyl chloride and isophthaloyl chloride in 150ml of dichloromethane to form an organic phase with a certain concentration. Slowly drop the organic phase into the inorganic phase at a temperature of 10°C. After stirring and reacting for 2 hours, slowly add 0.0035mol (0.317g) of acryloyl chloride monomer dropwise at 10°C. The following reaction was carried out for 1 hour. Remove dichloromethane and water, and obtain terminal olefin-based polyarylate after drying, and use GPC-MwA gel chromatography to measure the number-average molecular weight of polyarylate for 6300.

[0030] Preparation of polysiloxane-polyarylate block copolymer: Add 2 g (0.002 mol) of singl...

Embodiment 2

[0033] Preparation of fluorine-containing polyarylate with terminal olefin group: First, add bisphenol AF0.03mol (10.14g), 0.066mol (2.64g) NaOH, 80ml deionized water and 0.051g phase transfer catalyst in a three-necked flask, stir to make bisphenol AF is dissolved in water to form an inorganic phase. Dissolve 0.02mol (4.05g) of terephthaloyl chloride and 0.01mol (2.03g) of isophthaloyl chloride in 150ml of dichloromethane to form an organic phase with a certain concentration. Slowly drop the organic phase into the inorganic phase at a temperature of 0°C. After stirring for 5 hours, slowly add 0.0035mol (0.317g) of acryloyl chloride monomer dropwise at 0°C. The following reaction was carried out for 1 hour. Remove dichloromethane and water, and obtain olefin-terminated fluorine-containing polyarylate after drying, and use GPC-MwA gel chromatography to measure the number-average molecular weight of olefin-terminated fluorine-containing polyarylate for 48000.

[0034] Prepar...

Embodiment 3

[0037] Preparation of fluorine-containing polyarylate with terminal olefin group: First, add bisphenol AF0.03mol (10.14g), 0.066mol (2.64g) NaOH, 80ml deionized water and 0.051g phase transfer catalyst in a three-necked flask, stir to make bisphenol AF is dissolved in water to form an inorganic phase. Dissolve 0.01mol (2.03g) of terephthaloyl chloride and 0.02mol (4.05g) of isophthaloyl chloride in 150ml of dichloromethane to form an organic phase with a certain concentration. Slowly drop the organic phase into the inorganic phase at a temperature of 5°C. After stirring and reacting for 3 hours, slowly add 0.0035mol (0.317g) of acryloyl chloride monomer dropwise at 0°C. The following reaction was carried out for 5 hours. Remove dichloromethane and water, and obtain olefin-terminated fluorine-containing polyarylate after drying, and use GPC-MwA gel chromatography to measure the number-average molecular weight of olefin-terminated fluorine-containing polyarylate for 17000.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com