Silane crosslinked polyethylene cable material and preparation method

A technology of silane crosslinking and polyethylene, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems affecting the physical and mechanical properties and processing of cable materials, achieve good processing performance and cable surface quality, improve production efficiency, and quickly deliver linked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

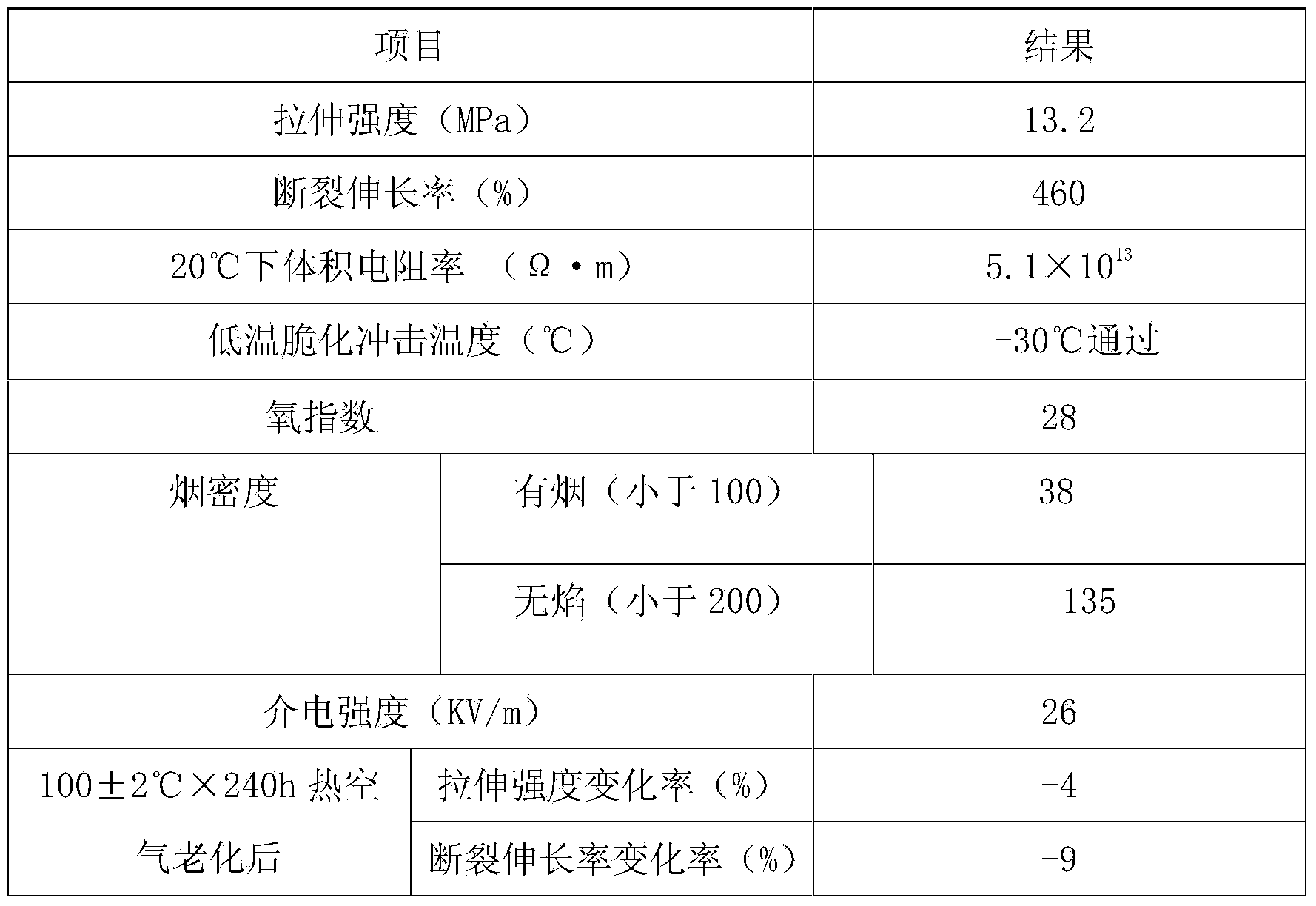

Examples

Embodiment Construction

[0013] A silane cross-linked polyethylene cable material, prepared from the following component raw materials by weight (kg):

[0014] Low-density polyethylene 85, high-density polyethylene 15, polyvinyl chloride 8, silane coupling agent KH5502, antioxidant 0.1, nano-titanium dioxide 0.3, di-n-octyltin dilaurate 0.2, light calcium carbonate 18, talcum powder 1.5, Modified filler 8, asphalt 0.3, aluminum hypophosphite 18, polyisobutylene 1, polytetrafluoroethylene 1.5.

[0015] Wherein, the modified filler is prepared by the following method:

[0016] Calcinate the diatomite at 540°C for 3.5 hours, take it out, add 3% sodium hydroxide solution and grind it for 1.5 hours, then add 13% hydrochloric acid solution, adjust the pH value to 4-5, and age for 12 hours. Add sodium hydroxide solution to adjust the pH of the grinding liquid to be neutral, filter and dry to obtain filler powder, then, add camphor essential oil equivalent to 1% of powder weight, 1% nano-carbon, 2% aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com