Ultraviolet curing adhesive for liquid crystal display television side frame and preparation method of ultraviolet curing adhesive

A technology of LCD TV and ultraviolet light, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of product yield decline and low precision, so as to save production costs, improve production efficiency, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

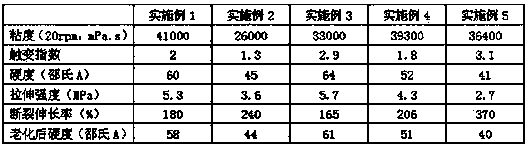

Examples

Embodiment 1

[0028] Add 100 grams of polyester diol with a hydroxyl value of 56 (Qingdao Xinyutian Chemical POL-156) into the reactor, vacuum dehydrate at 115°C for 2 hours, cool down to below 40°C, and add 13.1 grams of toluene Diisocyanate, 0.1 g of dibutyltin dilaurate, react at 60°C for 2.5 hours, add 0.3 g of p-hydroxyanisole, 0.45 g of antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl ) octadecyl propionate, 6.1 grams of hydroxyethyl acrylate, continue to react at 75 ° C for 2 hours, take a sample and measure the infrared spectrum to confirm that the infrared absorption peak of the isocyanate group disappears, and the material is cooled and discharged. polymer [DP1].

[0029] The preparation method of the inert polyurethane prepolymer [IU1] is the same as that of [DP1], except that the amount of toluene diisocyanate added is 17.4 g, 6.1 g of hydroxyethyl acrylate is replaced by 11.6 g of n-butanol, and the rest of the added amount is the same.

[0030] 36.5g of difunctional polyureth...

Embodiment 2

[0032]Add 100 grams of polyester diol with a hydroxyl value of 38 (Qingdao Xinyutian Chemical POL-138) into the reactor, vacuum dehydrate at 115°C for 2 hours, cool down to below 40°C, and add 8.1 grams of toluene Diisocyanate, 0.1 g of dibutyltin dilaurate, react at 60°C for 2.5 hours, add 0.3 g of p-hydroxyanisole, 0.45 g of antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl ) Octadecyl propionate, 4.1 g of β-hydroxybutyl acrylate, continue to react at 75°C for 2 hours, take a sample and measure the infrared spectrum to confirm that the infrared absorption peak of the isocyanate group disappears, and the material is cooled and discharged to obtain a difunctional polyurethane Acrylate prepolymer [DP2].

[0033] The preparation method of the inert polyurethane prepolymer [IU2] is the same as that of [DP2], except that the amount of toluene diisocyanate added is 11.6 g, 4.1 g of 4-hydroxybutyl acrylate is replaced by 3.1 g of ethanol, and the rest of the added amount is the same....

Embodiment 3

[0036] Add 100 grams of polyester diol with a hydroxyl value of 112 (Qingdao Xinyutian Chemical POL-3112) into the reactor, vacuum dehydrate at a temperature of 115°C for 2 hours, cool down to below 40°C, and add 22.6 grams of toluene Diisocyanate, 0.1 g of dibutyltin dilaurate, react at 60°C for 2.5 hours, add 0.3 g of p-hydroxyanisole, 0.45 g of antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl ) Octadecyl propionate, 8.2 g of β-hydroxypropyl acrylate, continue to react at 75°C for 2 hours, take a sample and measure the infrared spectrum to confirm that the infrared absorption peak of the isocyanate group disappears, and the material is cooled and discharged to obtain a difunctional polyurethane Acrylate prepolymer [DP3].

[0037] The preparation method of the inert polyurethane prepolymer [IU3] is the same as that of [DP3], except that the amount of toluene diisocyanate added is 34.8 g, 8.2 g of hydroxypropyl acrylate is replaced by 39.1 g of lauryl alcohol, and the rest of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com