Environment-friendly, low-damage and clay-free deep water constant-rheology drilling fluid

An environment-friendly, clay-free technology, used in clay-free deep-water constant rheological drilling fluids, environment-friendly, low-damage fields, can solve problems such as large viscosity fluctuations, lost circulation, and difficult pressure control, and achieve strong shear dilution. , to prevent slurry running, the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

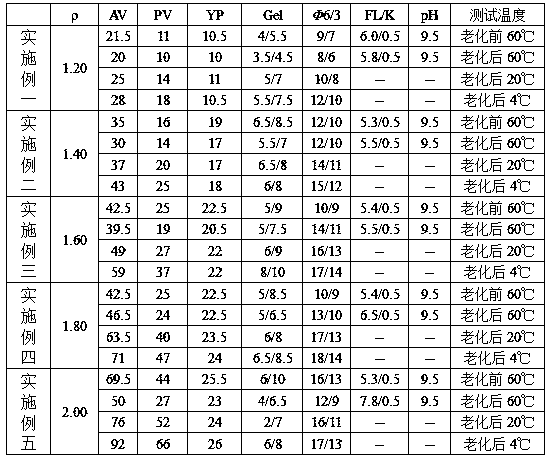

Embodiment 1

[0044] An environment-friendly, low-damage, clay-free deep-water constant rheological drilling fluid, prepared in 1m 3 The following masses of components are required: 2.5 kg sodium carbonate, 1 kg sodium hydroxide, 4.5 kg xanthan gum DHV, 70 kg KCl, 30 kg NaCl, 1 kg polyanionic cellulose PAC, 20 kg modified starch JHF, 30 kg polymeric alcohol JLX-A, 5 kg superfine calcium carbonate QS-2, 200 kg barite powder, 0.95m 3 seawater.

Embodiment 2

[0046] An environment-friendly, low-damage, clay-free deep-water constant rheological drilling fluid, prepared in 1m 3 The following masses of components are required: 2.5 kg sodium carbonate, 1 kg sodium hydroxide, 4.5 kg xanthan gum DHV, 70 kg KCl, 30 kg NaCl, 1 kg polyanionic cellulose PAC, 20 kg modified starch JHF, 30 kg polymeric alcohol JLX-A, 5 kg superfine calcium carbonate QS-2, 400 kg barite powder, 0.89m 3 seawater.

Embodiment 3

[0048] An environment-friendly, low-damage, clay-free deep-water constant rheological drilling fluid, prepared in 1m 3 The following masses of components are required: 2.5 kg sodium carbonate, 1 kg sodium hydroxide, 5 kg xanthan gum DHV, 70 kg KCl, 30 kg NaCl, 1 kg polyanionic cellulose PAC, 20 kg modified starch JHF, 40 kg polymeric alcohol JLX-A, 5 kg superfine calcium carbonate QS-2, 690 kg barite powder, 0.84m 3 seawater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com