Fatty acid mixture amide propyl betaine compound and application

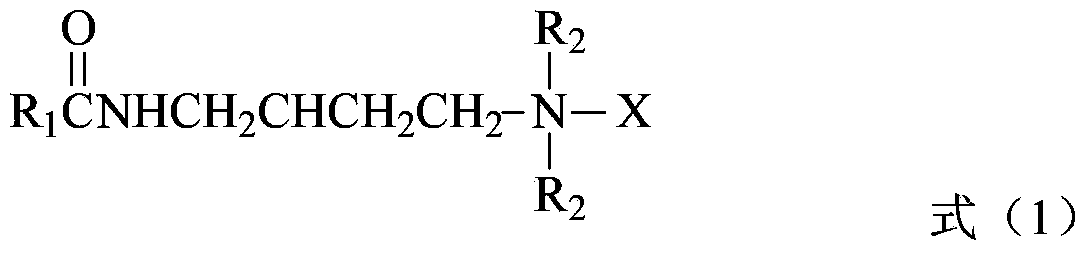

A technology of fatty acid amidopropyl beet and fatty acid amidopropyl sulfopropyl beet, which is applied in the field of chemical compound flooding composition, application of chemical compound flooding composition in tertiary oil recovery, and mixed fatty acid amidopropyl betaine compound, It can solve problems such as affecting application and poor solubility, and achieve the effects of diverse production raw materials, improved oil-water interface performance, and improved versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] (1) Preparation of rapeseed oil fatty acid

[0044] 1. Take rapeseed oil and put it into a high-pressure reactor, then add deionized water, hydrolyze it at 260°C and 5.0MPa for 8 hours, take samples to analyze the acid value and saponification value of fatty acids, and stop the reaction when the hydrolysis rate reaches more than 98%. Discharge.

[0045] 2. Preparation of rapeseed oil fatty acid amides

[0046] Add a certain amount of rapeseed oil fatty acid and N,N-dimethyl-1,3-propanediamine (the ratio of substances is 1:1.2) to the autoclave, react at 150-220°C for 6-10h, Rapeseed oil fatty acid amide can be prepared.

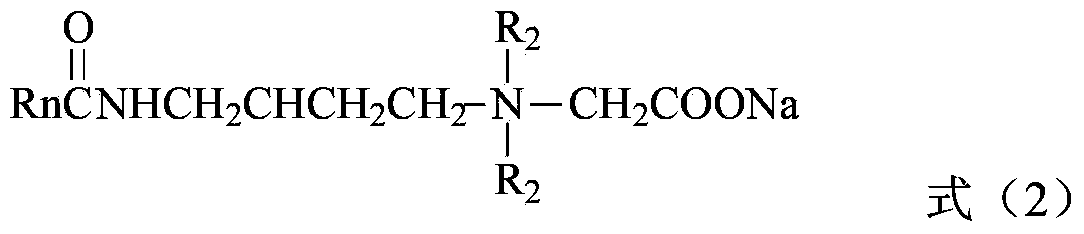

[0047] 3. Preparation of rapeseed oil fatty acid amidopropyl carboxyethyl betaine

[0048] Add rapeseed oil fatty acid amide and sodium chloroacetate (mass ratio: 1:1.05) into a four-neck round bottom flask, add isopropanol-water mixed solvent, and react at 70-80°C for more than 10 hours to obtain rapeseed oil Fatty acid amidopropyl carboxyethyl be...

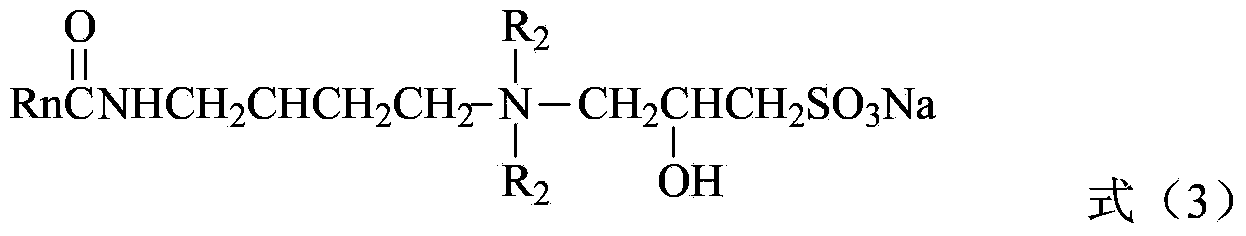

Embodiment 1

[0058] Example 1 Oil-water interfacial tension test in block 1 of reservoir 1

[0059] Rapeseed oil fatty acid amide propyl hydroxypropyl sultaine alone. The produced water of oil reservoir 1 block 1 was used to prepare rapeseed oil fatty acid amidopropyl hydroxypropyl sulfobetaine with mass concentrations of 0.05%, 0.10% and 0.20%, and polymer HPAM with a mass percentage concentration of 0.12% Measure the interfacial tension between the metachemical compound flooding composition and the crude oil in block 1 of reservoir 1.

[0060] Oleamidopropyl hydroxypropyl sultaine was used as a control. The test results are shown in Table 1.

[0061] Table 1. Test results of oil-water interfacial tension under the condition of block 1 in reservoir 1

[0062]

Embodiment 2

[0063] Example 2 Oil-water interfacial tension test in block 2 of reservoir 1

[0064] Rapeseed oil fatty acid amidopropyl carboxyethyl betaine and rapeseed oil fatty acid amidopropyl hydroxypropyl sulfobetaine are compounded to form a rapeseed oil fatty acid amidopropyl betaine compound. In terms of weight ratio, rapeseed Oil fatty acid amidopropyl carboxyethyl betaine: rapeseed oil fatty acid amidopropyl hydroxypropyl sultaine=70:30. Alkali-free binary chemical compounding with rapeseed oil fatty acid amidopropyl betaine compound mass concentrations of 0.05%, 0.10% and 0.20% and polymer HPAM mass percentage concentration of 0.15% was prepared with the produced water of oil reservoir 1 block 2 The flooding composition was used to measure the interfacial tension between it and the crude oil in block 2 of reservoir 1.

[0065] Oleamidopropyl carboxyethyl betaine was used as a control. The test results are shown in Table 2.

[0066] Table 2 Test results of oil-water interfaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com