Preparation of red soil-base polymer catalyst and application of catalyst in preparation of hydrogen energy

A polymer and red mud-based technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrogen production, etc., can solve the problem of not finding red mud-based polymer catalysts and energy consumption , secondary pollution and other issues, to achieve the effect of enriching catalyst types, no three wastes discharge, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

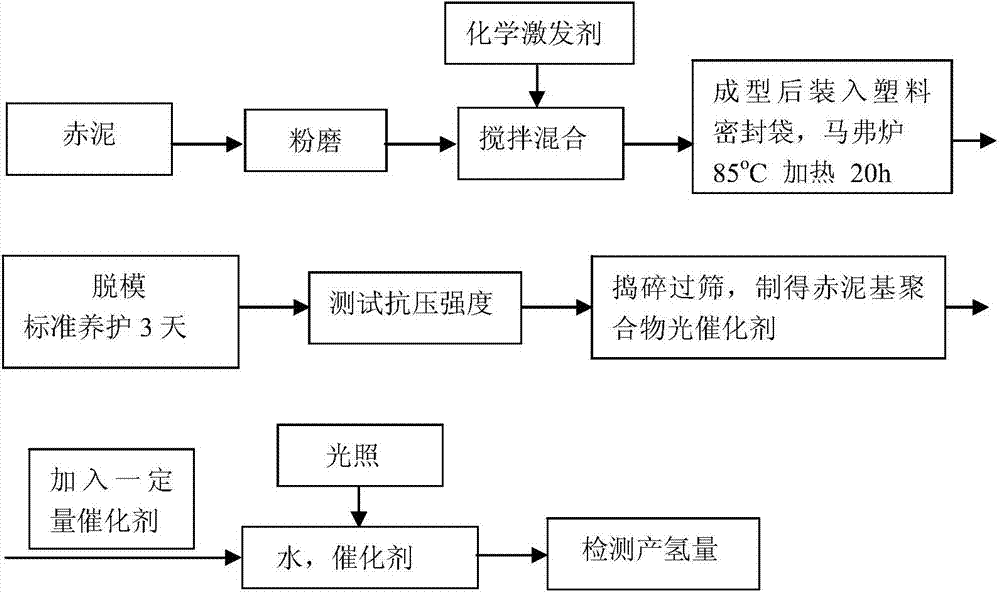

Method used

Image

Examples

Embodiment 1

[0076] Accurately weigh 900 grams of Guangxi Bayer process red mud, and use this as the basis for measurement (100%); adopt the external mixing method, and the amount of sodium silicate is 18% of the weight of Guangxi Bayer process red mud (hereinafter referred to as red mud) ; The mass ratio of water to red mud is 0.3.

[0077] The activator sodium silicate is dissolved in water to form an aqueous solution at room temperature. Pour the sodium silicate aqueous solution into a double-rotation and double-speed slurry mixer, then add red mud for high-speed stirring to form a uniformly mixed slurry, and put the slurry into a 30mm×30mm×40mm iron triple mold. Vibrate on the plastic sand vibrating table, and scrape it with a scraper to obtain a shaped red mud-based polymer. Put the formed red mud-based polymer into a plastic film bag and seal it, heat it at 85°C for 20 hours, then release it from the mold, and then maintain it for 3 days under standard curing conditions. 10.8MPa. ...

Embodiment 2

[0080] All the operation steps are the same as in Example 1, except that the dosage of the activator sodium silicate is 20% of the weight of the red mud, and the compressive strength of the red mud-based polymer is 17 MPa as measured by a compression tester.

Embodiment 3

[0082] All the operation steps are the same as in Example 1, except that the content of the activator sodium silicate is 23% of the weight of the Guangxi Bayer process red mud, and the compressive strength of the red mud-based polymer is 7.5 MPa measured by a compression tester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com