Industrial production method of chloromethyl pyridine derivative

A technology of chloromethylpyridine and a production method, applied in directions such as organic chemistry, can solve the problems of high production cost, difficult disposal of three wastes, long process flow, etc., and achieves the effects of reducing production cost, protecting the environment, and being highly competitive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the present invention, the industrial production method of a kind of chloromethylpyridine derivative of the present invention is described in further detail below in conjunction with embodiment:

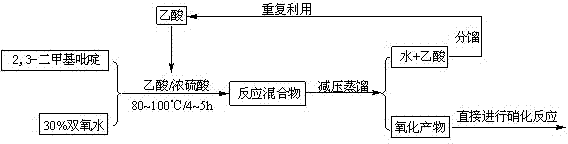

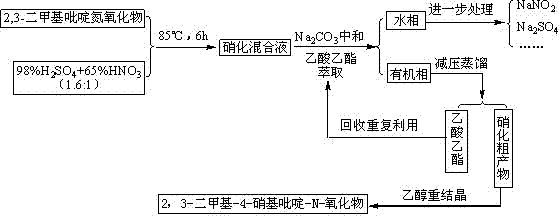

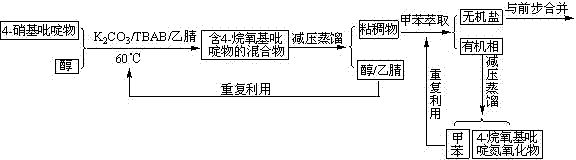

[0021] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the industrial production method of a chloromethylpyridine derivative of the present invention comprises five reaction steps including oxidation reaction, nitration reaction, substitution reaction, heavy row hydrolysis reaction and chloromethylation reaction.

[0022] 1. Oxidation reaction

[0023] Depend on figure 1 The oxidation reaction process flow chart shown shows that dilute 2,3-lutidine with 3 times the volume of acetic acid, add a catalytic amount of concentrated sulfuric acid dropwise, raise the temperature to 80~100°C, add 30% hydrogen peroxide dropwise, add dropwise After completion of the heat preservation reaction for 4-5 h, the reaction was com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com