A kind of intestinal mucosa protection and repair type enteral nutrition product and preparation method thereof

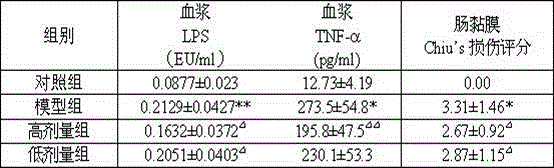

A technology of nutrition and products, which is applied in the field of functional nutrition for intestinal mucosal protection and repair and its preparation, can solve the problems that the efficacy and nutrition cannot be taken into account at the same time, the function of chemical drugs is single, and the ingredients of traditional Chinese medicine are complex, so as to enhance and promote Intestinal mucosal repair effect, reduce endotoxin translocation, and promote intestinal peristalsis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

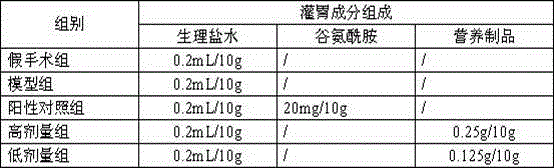

Method used

Image

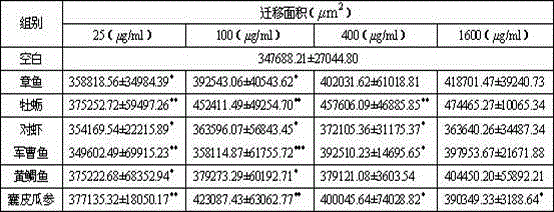

Examples

Embodiment 1

[0072] Raw materials that meet the relevant national edible standards are fresh oysters cultured in sea water. The materials are obtained by washing, shelling and viscera removal, adding 1:3 pure water according to the weight to volume ratio, and mixing until homogeneous. According to the weight of the material, add 1% trypsin, adjust the pH, keep the temperature at 40°C, and perform enzymatic hydrolysis for 7 hours. Centrifuge to remove the precipitate, and the supernatant is passed through an ultrafiltration membrane to obtain a peptide solution below 5000 Da, and then concentrated in a vacuum to obtain a small molecule peptide solution separated by enzymatic hydrolysis of oysters.

[0073] Take 2.0 parts of marine animal enzymatic hydrolysis and separation of small molecule peptide liquid (dry weight basis), 15.0 parts of soybean peptide, 4.0 parts of medium and long-chain fatty acid edible oil, 76 parts of maltodextrin, 2.0 parts of polydextrose, 0.5 part of stachyose, Ala ...

Embodiment 2

[0077] Raw materials that meet the relevant national edible standards are fresh octopus cultured in sea water, cleaned and removed from the viscera to obtain materials, added 1:3 purified water according to the weight-to-volume ratio, and crushed to homogenize. According to the weight of the material, add 3% pepsin, adjust the pH, keep the temperature at 40°C, and perform enzymatic hydrolysis for 6 hours. Centrifuge to remove the precipitate, and the supernatant is passed through an ultrafiltration membrane to obtain a peptide solution below 5000 Da, and then concentrated in a vacuum to obtain a small molecule peptide solution separated by enzymatic hydrolysis of octopus.

[0078] Take 10.0 parts of octopus enzymatic hydrolysis and separation of small molecule peptide liquid (dry weight basis), 15.0 parts of soybean peptide, 10.0 parts of medium and long-chain fatty acid edible oil, 43 parts of maltodextrin, 10.0 parts of soybean dietary fiber, 3.0 parts of raffinose, Arg- 9.0...

Embodiment 3

[0082] Raw materials that meet the relevant national edible standards are fresh cobia cultured in sea water, cleaned, scaled and viscerated to obtain materials, and purified water of 1:3 is added according to the weight-to-volume ratio, and crushed and homogenized. According to the weight of the material, add 2% papain, adjust the pH, keep the temperature at 50°C, and perform enzymatic hydrolysis for 8 hours. Centrifuge to remove the precipitate, and the supernatant is passed through an ultrafiltration membrane to obtain a peptide solution below 5000 Da, and then concentrated in a vacuum to obtain a cobia enzymatic hydrolysis and separation of small molecules.

[0083] Take cobia enzymatic hydrolysis and separation of small molecule peptide liquid 10.0 parts (dry weight basis), soybean peptide 5.0 parts, medium and long-chain fatty acid edible oil 4.0 parts, maltodextrin 78.0 parts, soybean dietary fiber 2.0 parts, fructooligosaccharides 0.5 parts, Gly -0.5 part of Gln, and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com