Sulfur-containing tail gas purifying and recycling method

A tail gas purification and tail gas technology, applied in chemical instruments and methods, sulfur compounds, separation methods, etc., can solve the problems of low economic value and high energy consumption of sodium sulfide products, and achieve the effect of reducing energy consumption and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

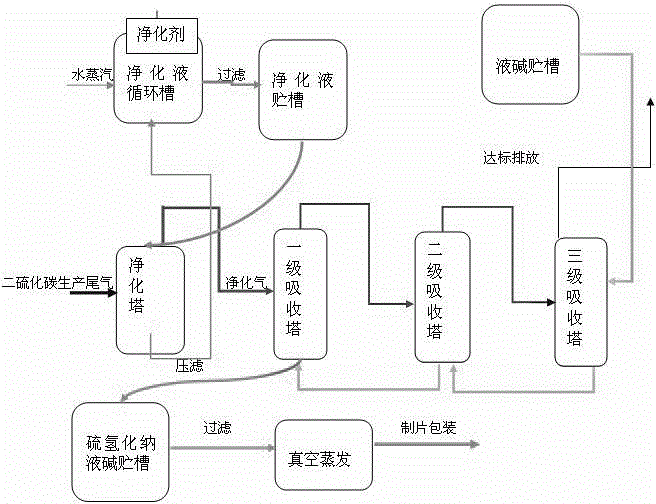

[0025] see figure 1 , the implementation process of the inventive method is as follows:

[0026] Firstly, the straight-through sulfur recovery method is used to recover the sulfur-containing tail gas (carbon disulfide tail gas produced from natural gas), according to the O in the air 2 The converted amount is H in the exhaust gas 2 The amount of 1-1.5 times the S content controls the amount of air dosage, so that the tail gas of the once-through sulfur recovery process is mainly hydrogen sulfide.

[0027] 1. Dissolve the purifying agent barium sulfide with steam, let it stand for precipitation and filter, and make a purification solution with a concentration required by the process (concentration is controlled at 25%), store it in the purification solution storage tank, and transport it to the purification treatment with a delivery pump The tower (1 / 3---1 / 2 liquid level of the tower body) is ready for use.

[0028] 2. Pass the tail gas into the purification treatment tower,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com