Electrolytic manganese waste slag sintered building brick and preparation method thereof

A technology for electrolytic manganese waste residue and a manufacturing method, which is applied in the field of building materials, can solve problems such as high product cost and complex formula, and achieve the effects of low production cost, simple ingredients and less coal consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 The electrolytic manganese waste slag used in this example is the waste slag produced by the electrolytic manganese prepared by the direct leaching method of manganese-poor high-iron manganese carbonate and manganese dioxide. The radioactive substance radium was tested by the building materials product quality inspection station of Guangxi Zhuang Autonomous Region. -226, Thorium-232 and Potassium-40 all do not exceed the standard.

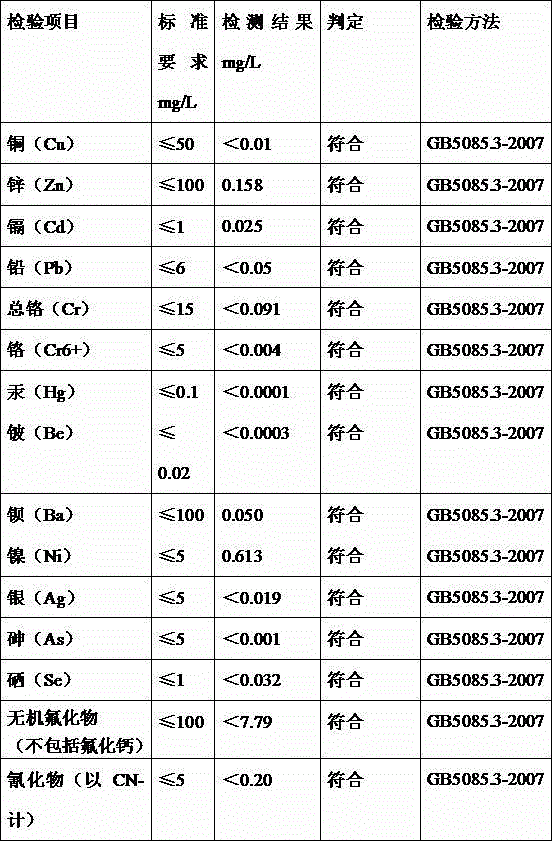

[0024] Such electrolytic manganese waste slag has been tested, and other indicators are as follows.

[0025]

[0026] It can be seen from the above data that they all meet the requirements of the standard and can fully guarantee the safe use of the product.

[0027] 10 parts by weight of coal gangue, 15 parts by weight of shale and 20 parts by weight of clay are pulverized to a fineness range of 2 to 3 mm, and then 45 parts by weight of electrolytic manganese waste residue is mixed according to a conventional method, stirred, an...

Embodiment 2

[0028] Example 2 The same electrolytic manganese waste slag as in Example 1 was used.

[0029] 18 parts by weight of coal gangue, 18 parts by weight of shale and 25 parts by weight of clay are pulverized to a fineness range of 2 to 3mm, and then 35 parts by weight of electrolytic manganese waste residue is mixed according to a conventional method, stirred, and then Aging for 25 hours, stirring again, and a series of processes to make the finished product.

Embodiment 3

[0030] Example 3 The same electrolytic manganese waste slag as in Example 1 was used.

[0031] 8 parts by weight of coal gangue, 8 parts by weight of shale and 12 parts by weight of clay are pulverized to a fineness range of 2 to 3 mm, and then 48 parts by weight of electrolytic manganese waste residue are mixed according to conventional methods, stirred, and then Aging for 72 hours, stirring again, and a series of processes to make the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com